A simple and rapid method for preparing ultramicroelectrode arrays

An ultra-micro electrode and fast technology, applied in the direction of material electrochemical variables, etc., can solve the problems of ultra-micro electrode array process complexity, time-consuming preparation, high cost, etc., and achieve the effect of convenient reassembly, saving time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

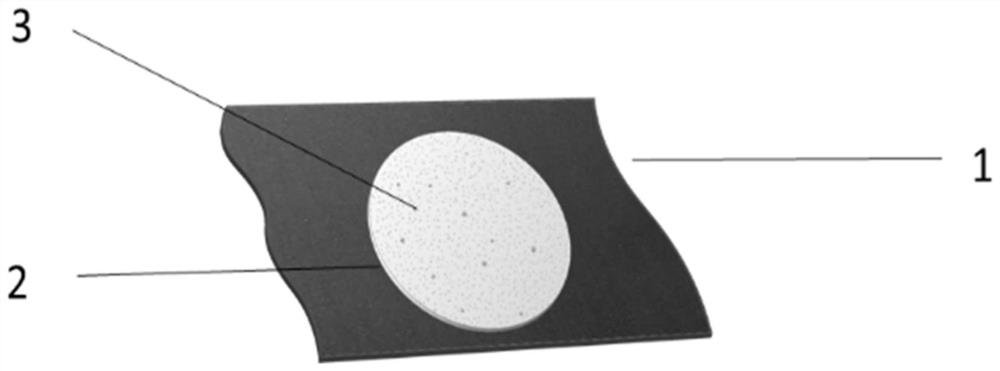

[0034] Embodiment 1: A simple and rapid method for preparing an ultra-micro electrode array in this embodiment is completed according to the following steps:

[0035] 1. Paste one side of the double-sided carbon conductive tape onto the metal-coated glass sheet flatly;

[0036] 2. Place the template with nano-pore size on the other side of the double-sided carbon conductive tape, then empty the air between the template and the double-sided carbon conductive tape, and finally compact it to obtain an assembled metal sheet;

[0037] The material of the template with nano-pore size described in step 2 is alumina porous membrane or polycarbonate porous membrane;

[0038] 3. Open a circular hole at the bottom of the electrolytic cell, then place the assembled metal sheet on the bottom of the electrolytic cell, align the template with the circular hole, seal it with an O-ring, and then use screws to assemble the base of the electrolytic cell and assemble it. The metal sheet and the ...

specific Embodiment approach 2

[0041] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the double-sided carbon conductive tape described in step 1 has a thickness of 150-170 μm, a width of 23-28 mm, and a length of 18-22 mm. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0042]Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the double-sided carbon conductive tape described in step 1 is made of non-woven fabric as the base material, and both sides contain carbon powder as conductive filler. Acrylic pressure sensitive adhesive, resistivity (1.8±0.2)×10 4 Ωcm. Other steps are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com