Nano polysaccharide compound and preparation method and application thereof

A compound and polysaccharide technology, applied in the fields of drug delivery, pharmaceutical formulation, medical science, etc., can solve the problems of high energy consumption, time-consuming and labor-intensive, and inability to provide physical and chemical properties at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0053] Take 50g of Ganoderma tsugae (Ganoderma tsugae) fiber extracted by hot water (purchased from Kang Jian, Nantou, Taiwan, China), and decompose it with 400mL of 1N sodium hydroxide at 85°C for 24 hours. After decomposition, the reaction residue was collected and washed with deionized water to remove residual sodium hydroxide. Then use hydrogen peroxide (the weight ratio of hydrogen peroxide and reaction residue is 1:3) to decolorize to obtain a syrupy mixture. After decolorization (bleaching), the decolorized slurry mixture is thoroughly washed with secondary deionized water. The polysaccharide complex (SC) referred to in this disclosure is obtained by filtering and freeze-drying the cleaned slurry mixture.

[0054] The nanometerization of the polysaccharide complex includes physical methods and chemical methods, and in Preparation Example 1, the physical method of nanometerization will be described as follows. Disperse 4 g of the polysaccharide complex in 200 mL of sec...

preparation example 2

[0056] The difference from Preparation Example 1 is that in Preparation Example 2, after the step of collecting the polysaccharide complex, the nano-polysaccharide complex will be produced by chemical oxidation. Specifically, the chemical method in Preparation Example 2 was performed by an oxidation system with TEMPO.

[0057] 5 g of the polysaccharide complex was dispersed in 375 mL of secondary deionized water containing 0.0625 g of TEMPO and 0.625 g of sodium bromide to obtain a mixed solution. The TEMPO-mediated oxidation of the mixed solution (slurry) with polysaccharide complexes will be initiated after adding 5% sodium hypochlorite (NaClO) aqueous solution. There are 5 kinds of NaClO addition amounts (1.66, 3.33, 5.00, 6.67 and 10 mmol NaClO per gram of polysaccharide complex, respectively), and then add the aforementioned 5 kinds of NaClO addition amounts to the mixed solution, and keep stirring at room temperature. During the reaction, 5N sodium hydroxide and 1N hydr...

Embodiment 1

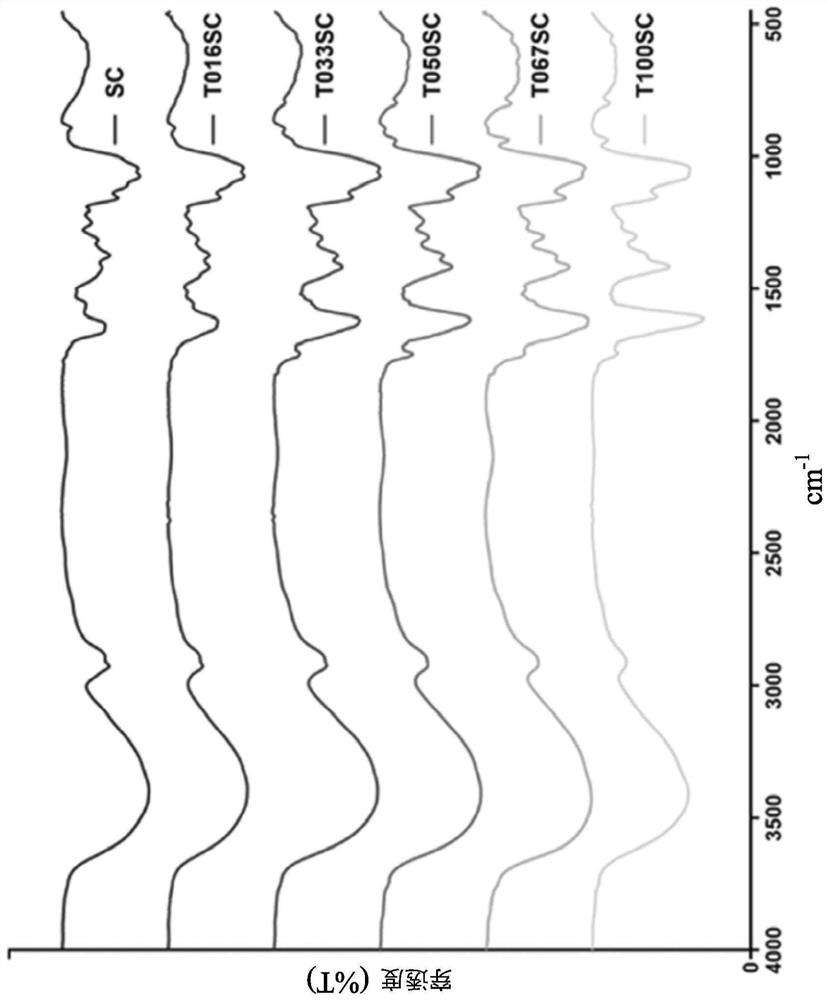

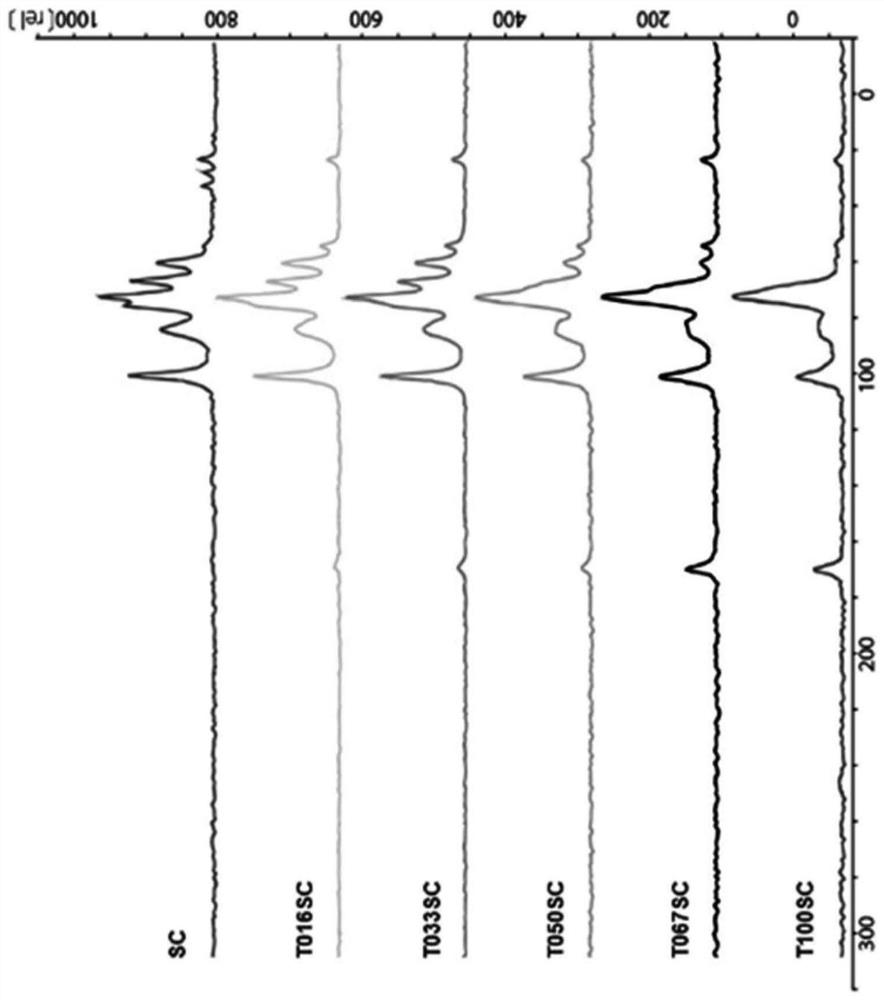

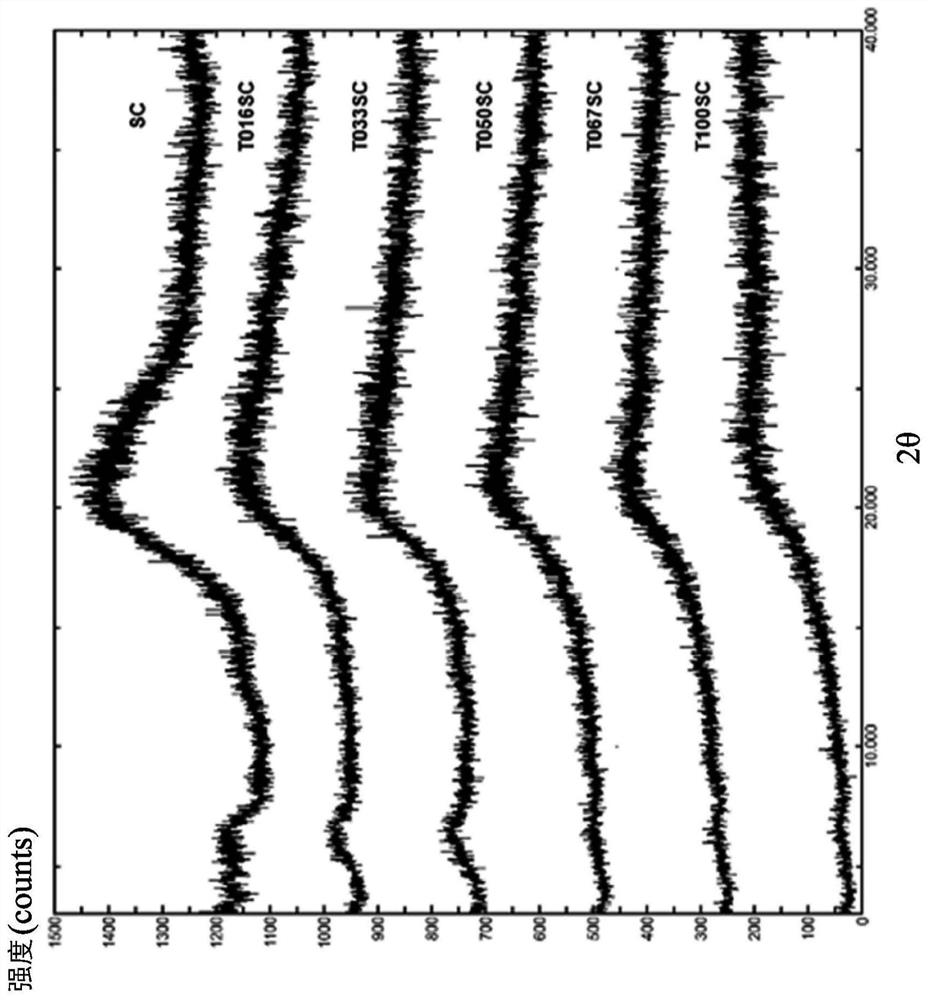

[0061] For the various properties and detection data of the above nano-polysaccharide complexes, please refer Figure 1A to Figure 1E . Regarding the code, SC in the figure represents the polysaccharide complex; SCN3 represents the nano-polysaccharide compound made by 3 cycles through the high-pressure homogenizer; SCN5 represents the nano-polysaccharide compound made by 5 cycles through the high-pressure homogenizer ; CN10 represents the nano-polysaccharide compound made by carrying out 10 cycles through a high-pressure homogenizer; T016SC represents the nano-polysaccharide compound made by oxidation of 1.66 mmol NaClO per gram of polysaccharide compound; Nano-polysaccharide complexes made by oxidation of mmol NaClO; T050SC represents nano-polysaccharide complexes produced by oxidation of 5.0 mmol NaClO per gram of polysaccharide complexes; T067SC represents nano-polysaccharide complexes produced by oxidation of 6.67 mmol NaClO per gram of polysaccharide complexes Polysaccha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com