Preparation method and application of photocatalyst material with magnetic core-shell structure

A photocatalyst, core-shell technology, applied in organic compound/hydride/coordination complex catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve pollution, low catalyst recycling efficiency, and energy consumption big problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

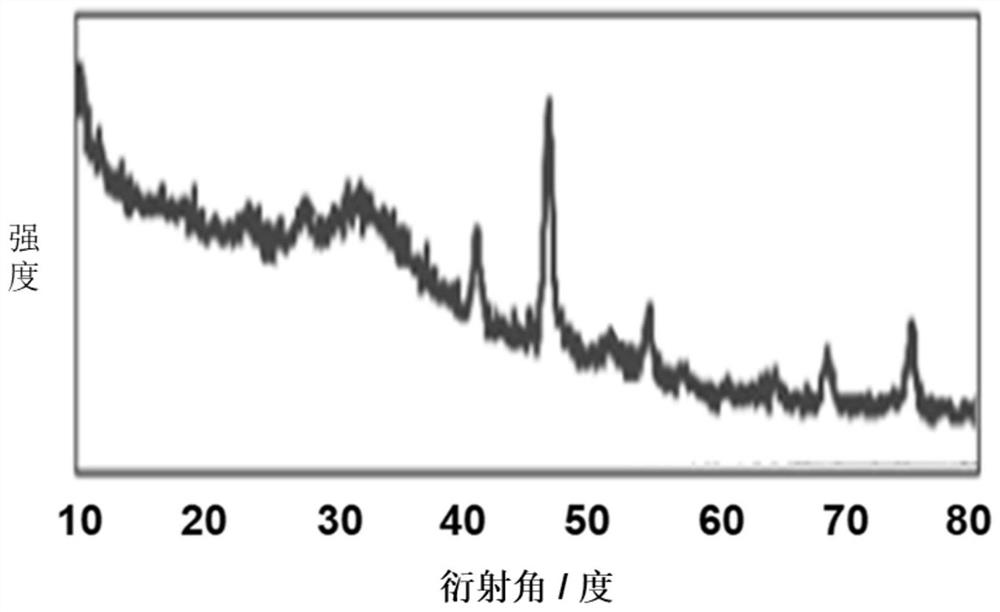

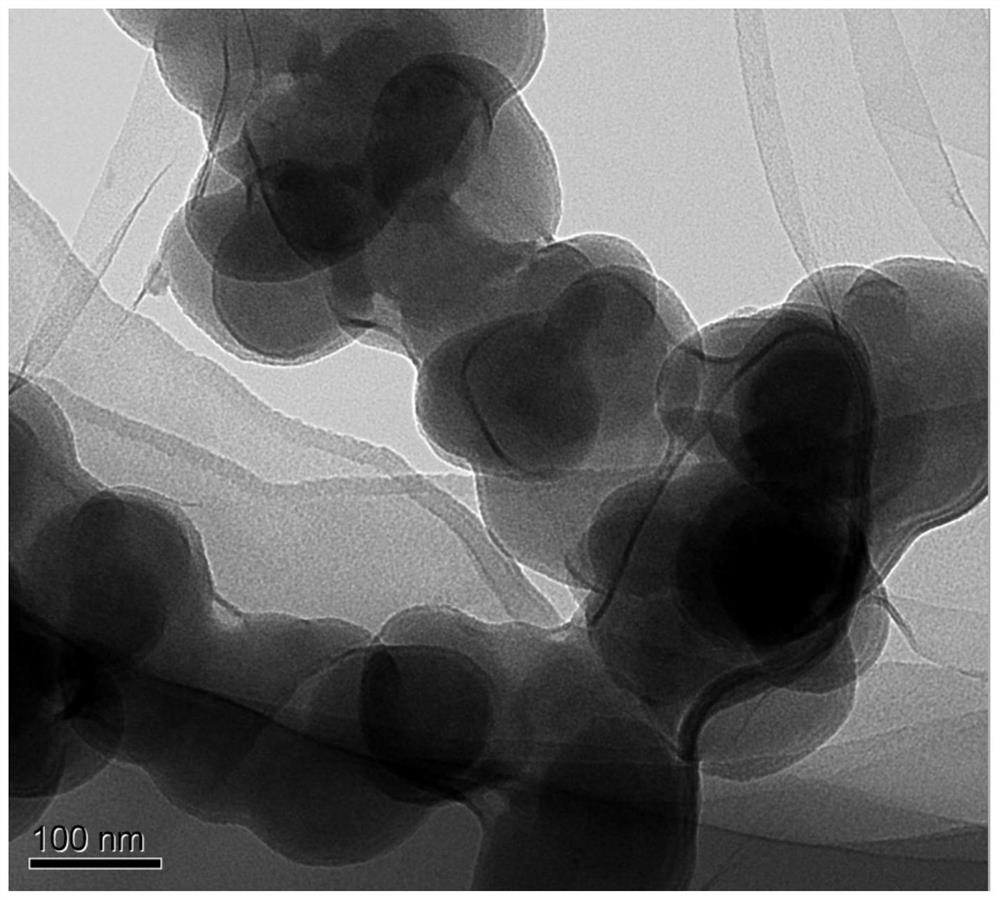

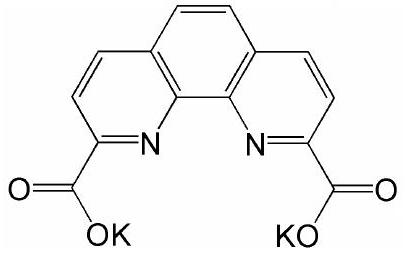

[0027] 1.0g of magnetic Fe 3 o 4 @SiO 2 The composite nanoparticles were suspended in 20 mL of anhydrous methanol solvent. After ultrasonication for 20 min, 0.1 g of organic ligand 1,10-phenanthroline-2,9-dicarboxylate potassium (phenCOOK) was added, and then the mixture was Reflux for 12 h, cool to room temperature, centrifuge to separate the precipitate, wash with anhydrous methanol three times, and dry in vacuum to obtain magnetic Fe containing phenCOO 3 o 4 @SiO 2 composite nanoparticles.

[0028] 1.0 g of magnetic Fe containing phenCOO 3 o 4 @SiO 2 Disperse the composite nanoparticles into 20mL of dry methanol, then slowly add 10mL of 0.01g / mL palladium acetate methanol solution dropwise, the mixture was refluxed under nitrogen atmosphere for 12h, cooled to room temperature, centrifuged to separate the precipitate, washed three times with anhydrous methanol , dried under vacuum to obtain magnetic Fe containing Pd-phenCOO 3 o 4 @SiO 2 Composite nanoparticles, ab...

Embodiment 2

[0030] 1.0g of magnetic Fe 3 o 4 @SiO 2 The composite nanoparticles were suspended in 30 mL of anhydrous ethanol solvent. After ultrasonication for 30 min, 0.1 g of organic ligand 1,10-phenanthroline-2,9-dicarboxylate potassium (phenCOOK) was added, and the mixture was heated under a nitrogen atmosphere. Reflux for 8h, cool to room temperature, centrifuge to separate the precipitate, wash with absolute ethanol three times, and dry in vacuum to obtain magnetic Fe containing phenCOO 3 o 4 @SiO 2 composite nanoparticles.

[0031] 1.0 g of magnetic Fe containing phenCOO 3 o 4 @SiO 2Disperse the composite nanoparticles into 30mL of dry ethanol, then slowly add 15mL of 0.01g / mL palladium dichloride ethanol solution dropwise, the mixture was refluxed under nitrogen atmosphere for 8h, cooled to room temperature, centrifuged to separate the precipitate, and washed with absolute ethanol After three times, vacuum drying yielded magnetic Fe containing Pd-phenCOO 3 o 4 @SiO 2 Co...

Embodiment 3

[0033] 1.0g of magnetic Fe 3 o 4 @SiO 2 The composite nanoparticles were suspended in 30 mL of anhydrous methanol solvent. After ultrasonication for 30 min, 0.1 g of organic ligand 1,10-phenanthroline-2,9-dicarboxylate potassium (phenCOOK) was added, and then the mixture was Reflux for 6 h, cool to room temperature, centrifuge to separate the precipitate, wash with anhydrous methanol three times, and dry in vacuum to obtain magnetic Fe containing phenCOO 3 o 4 @SiO 2 composite nanoparticles.

[0034] 1.0 g of magnetic Fe containing phenCOO 3 o 4 @SiO 2 Disperse the composite nanoparticles into 20mL of dry methanol, then slowly add 20mL of 0.01g / mL palladium nitrate methanol solution dropwise, the mixture was refluxed under nitrogen atmosphere for 6h, cooled to room temperature, centrifuged to separate the precipitate, washed three times with anhydrous methanol , dried under vacuum to obtain magnetic Fe containing Pd-phenCOO 3 o 4 @SiO 2 Composite nanoparticles, abbr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com