Anti-UV and antibacterial extinction chinlon chip and preparation method thereof

A nylon and slicing technology, applied in the manufacture of rayon, single-component polyamide rayon, chemical characteristics of fibers, etc., can solve problems such as breakage, decreased fiber strength, and non-smooth fiber surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

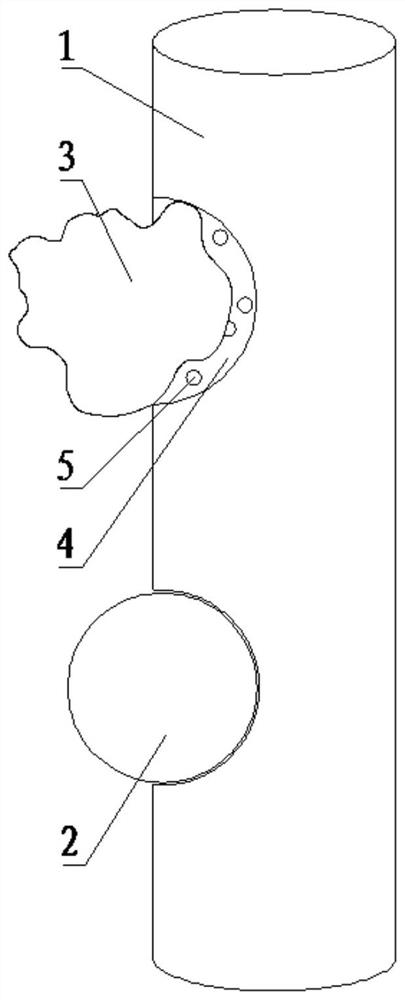

Method used

Image

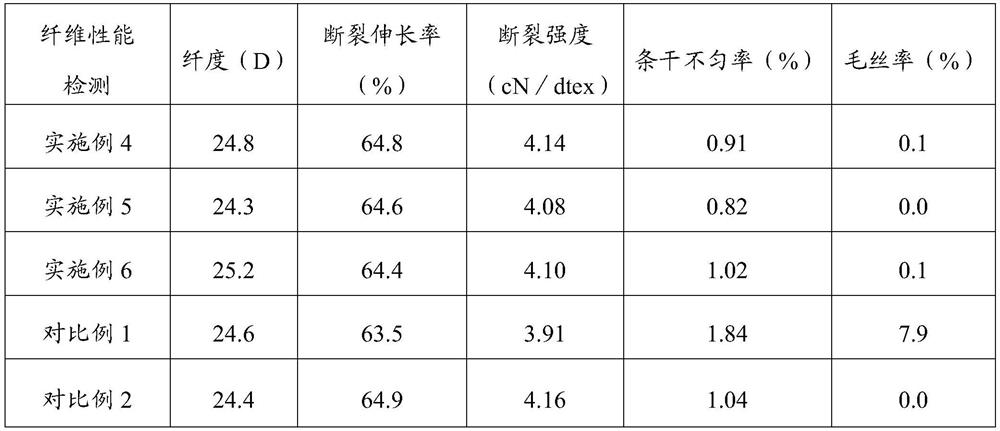

Examples

preparation example Construction

[0025] Further, the preparation method of the nano-zinc oxide composite particles includes the following steps;

[0026] Step 1. Add n-butanol to desalted water, add polyether polyol (such as polyether F127) after dissolving, add acid to adjust the pH to 1.8-2.5, and then add tetraethyl orthosilicate (such as TEOS-28) dropwise After the dropwise addition is completed, heat to 40-50°C and keep stirring for 24 hours, then raise the temperature to 100-110°C, and let it stand for 24 hours to obtain a white precipitate, which is filtered with a 0.22 μm filter membrane, and the retained material on the filter membrane is washed, Calcined after drying to obtain mesoporous silica;

[0027] Step 2. Add the zinc acetylacetonate mixture into ethanol (100%), then add the mesoporous silica obtained in step 1, heat and stir at 70° C. for 5-8 hours, collect the remaining white powder, and then wash it with ethanol. Calcining after drying to obtain nano zinc oxide composite particles.

[00...

Embodiment 1

[0055] Anti-UV, antibacterial matting nylon slices, by weight percentage, are composed of 1.75% titanium dioxide-nanometer zinc oxide composite particle preparation solution, 0.4% acid, 0.22% amine and the balance of caprolactam;

[0056] In percent by weight, the titanium dioxide-nanometer zinc oxide composite particle formulation solution includes 22.2% of titanium dioxide matting agent and 0.12% of nano-zinc oxide composite particles;

[0057] The nano-zinc oxide composite particles are composed of nano-zinc oxide particles and organic silicon TEOS-28 coated on the periphery of the nano-zinc oxide particles;

[0058] The titanium dioxide matting agent is composed of titanium dioxide particles and a composite layer coated on the outside of the titanium dioxide particles, and the composite layer sequentially includes an inorganic silicon compound layer, a metal compound layer and an organic polymer coating layer from the inside to the outside;

[0059] The titanium dioxide ma...

Embodiment 2

[0064] The anti-UV and antibacterial matting nylon slices are composed of 1.58% titanium dioxide-nanometer zinc oxide composite particle preparation solution, 0.26% acid, 0.15% amine and the balance of caprolactam by weight percentage;

[0065] In percent by weight, the titanium dioxide-nanometer zinc oxide composite particle preparation solution includes 21.5% of titanium dioxide matting agent and 0.08% of nano-zinc oxide composite particles;

[0066] The nano-zinc oxide composite particles are composed of nano-zinc oxide particles and organic silicon TEOS-28 coated on the periphery of the nano-zinc oxide particles;

[0067] The titanium dioxide matting agent is composed of titanium dioxide particles and a composite layer coated on the outside of the titanium dioxide particles, and the composite layer sequentially includes an inorganic silicon compound layer, a metal compound layer and an organic polymer coating layer from the inside to the outside;

[0068] The metal compoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com