Full-biodegradable pressure-sensitive adhesive and preparation method thereof

An all-biological, pressure-sensitive adhesive technology, applied in the direction of adhesives, adhesive additives, polymer adhesive additives, etc., can solve the problems of non-biodegradable products, poor environmental protection, poor tape performance, etc., to achieve safety and environmental protection in the preparation process , Simple and low cost, the effect of reducing the temperature of hot melt coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

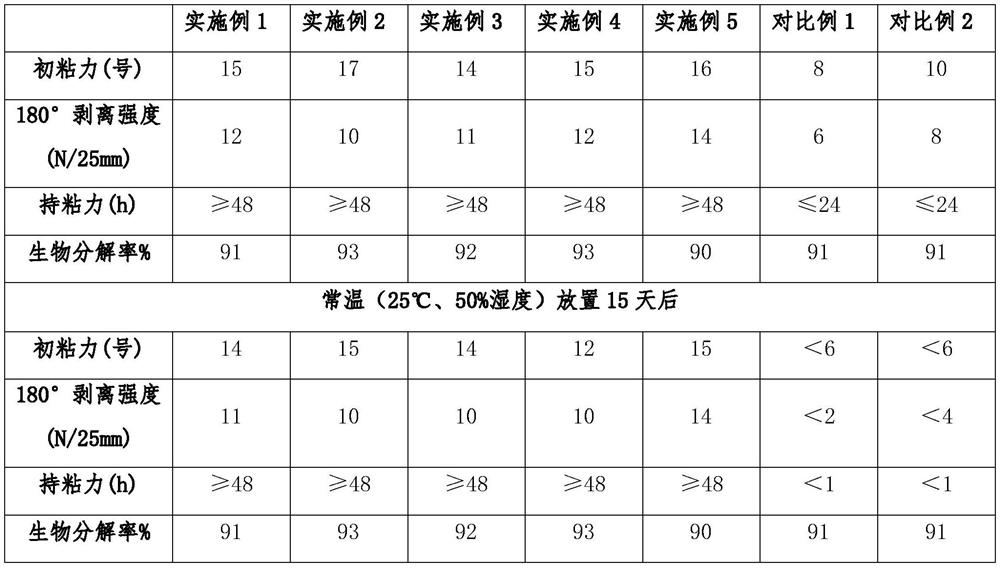

Examples

Embodiment 1

[0035] 1. Preparation of fully biodegradable elastomer:

[0036] Add 4kg of terephthalic acid, 4kg of isophthalic acid, 8kg of adipic acid, 14kg of butanediol, and 125g of trimethylolpropane into a reaction kettle with a distillation column, and react at -0.05MPa, 230°C, The by-product water and tetrahydrofuran are discharged into the collection tank through the rectification tower. When the produced water reaches the theoretical value, 20g of tetrabutyl titanate and 10g of triphenyl phosphate are put in, the temperature is raised to 270°C, and the reaction is performed at -0.1MPa first. After 1 hour, switch to high vacuum and continue to react at 100pa. When the stirring power of the motor reaches the set value, the material is discharged to obtain a fully biodegradable elastomer;

[0037] 2. Preparation of lactic acid oligomers:

[0038] The D,L-lactic acid aqueous solution with a mass concentration of 90% is added to the first reaction kettle at a rate of 15kg / h. The first...

Embodiment 2

[0050] Different from Example 1 is the modulation of full biological pressure-sensitive adhesive:

[0051] The above 70 parts of fully biodegradable elastomers, 28 parts of 300-600D, L-lactic acid oligomers, 1 part of 600-2000D, L-lactic acid oligomers, 1 part of glycerol tribenzoate, 0.5 parts of diphosphite Add pentaerythritol diisodecyl ester into the reaction kettle, stir and mix for 15 minutes at 180°C, and then discharge to obtain a finished biodegradable pressure-sensitive adhesive.

Embodiment 3

[0053] Different from Example 1 is the modulation of full biological pressure-sensitive adhesive:

[0054] The above 70 parts of fully biodegradable elastomer, 1 part of 300-600D, L-lactic acid oligomer, 21 parts of 600-2000D, L-lactic acid oligomer, 8 parts of adipate-propylene glycol-butylene glycol ester, 0.5 Parts of pentaerythritol diisodecyl diphosphite were added to the reaction kettle, stirred and mixed for 15 minutes at 180°C, and then discharged to obtain a finished biodegradable pressure-sensitive adhesive.

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com