Method for recycling positive electrode material of waste nickel-cobalt-manganese ternary lithium battery

A technology of ternary lithium battery and cathode material, applied in battery recycling, waste collector recycling, secondary battery, etc., can solve problems such as complex recycling operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

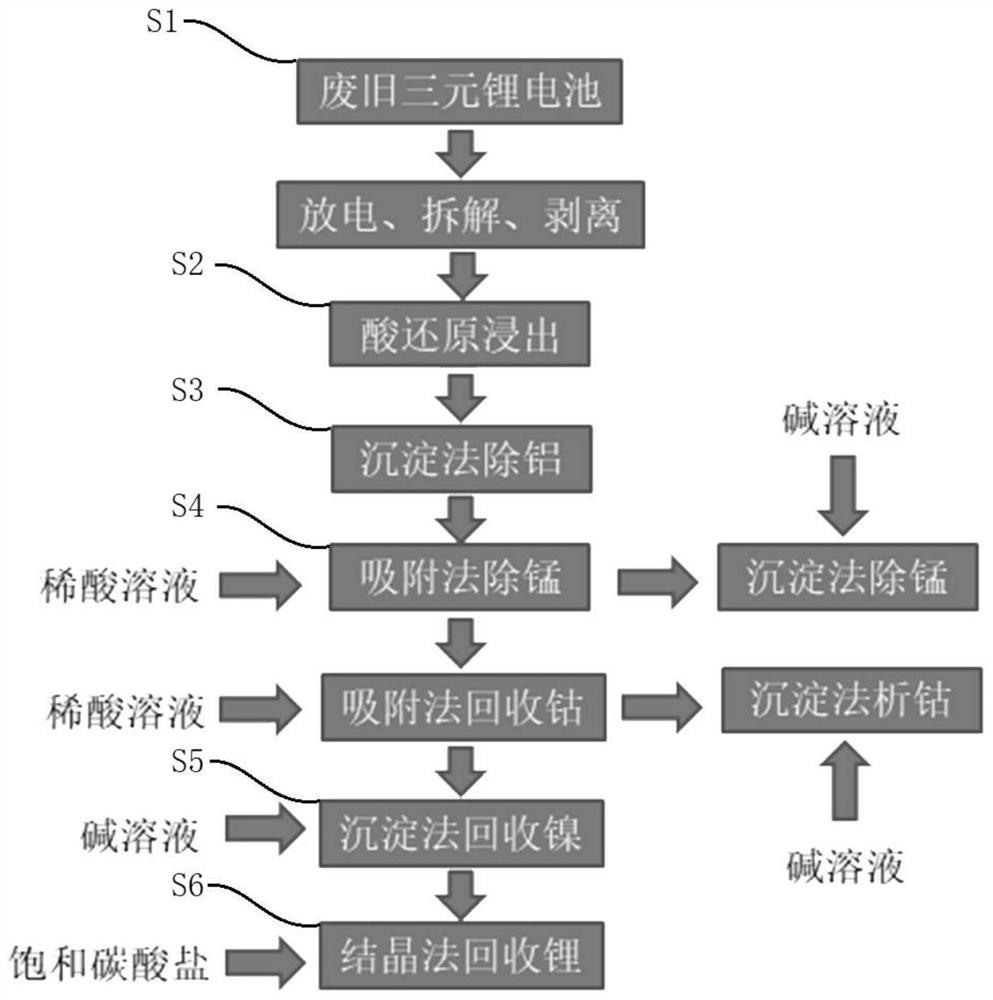

[0027] Such as figure 1 As shown, the recovery process of the waste nickel-cobalt-manganese ternary lithium battery cathode material in this embodiment is as follows:

[0028] S1, put the waste nickel-cobalt-manganese ternary lithium battery in 1.5mol / L NaCl solution for discharge treatment, wash and dry the waste nickel-cobalt-manganese ternary lithium battery after discharge, disassemble and peel off, and obtain the powder form positive electrode material; the concentration is 5.0wt% sulfuric acid solution to the positive electrode material leaching of waste nickel-cobalt-manganese ternary lithium battery for 10 ~ 60min, the solid-liquid ratio of positive electrode material and sulfuric acid solution is 50g / g; the slurry obtained after leaching Material is through pressure filtration, obtains the leach solution A containing nickel-cobalt-manganese-lithium;

[0029] S2, adding sulfuric acid solution with a concentration of 2.0wt% and hydrogen peroxide with a concentration of...

Embodiment 2

[0041] Such as figure 1 As shown, the recovery process of the waste nickel-cobalt-manganese ternary lithium battery cathode material in this embodiment is as follows:

[0042] S1, put the waste nickel-cobalt-manganese ternary lithium battery in 1.5mol / L NaCl solution for discharge treatment, wash and dry the waste nickel-cobalt-manganese ternary lithium battery after discharge, disassemble and peel off, and obtain the powder form positive electrode material; the concentration is 5.0wt% sulfuric acid solution to the positive electrode material leaching of waste nickel-cobalt-manganese ternary lithium battery for 10 ~ 60min, the solid-liquid ratio of positive electrode material and sulfuric acid solution is 50g / g; the slurry obtained after leaching Material is through pressure filtration, obtains the leach solution A containing nickel-cobalt-manganese-lithium;

[0043] S2, adding sulfuric acid solution with a concentration of 1.0 wt% and hydrogen peroxide with a concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com