Impact-resistant bamboo bundle-rubber composite board as well as preparation method and application thereof

A composite board and impact-resistant technology, which is applied in the direction of chemical instruments and methods, manufacturing tools, wood layered products, etc., can solve the problems of limited application range, poor impact resistance and damping internal friction performance, and complicated installation process, so as to achieve improvement Safety and comfort, improved impact resistance, high strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention provides the preparation method of impact-resistant bamboo beam-rubber composite plate described in above-mentioned technical scheme, comprises the following steps:

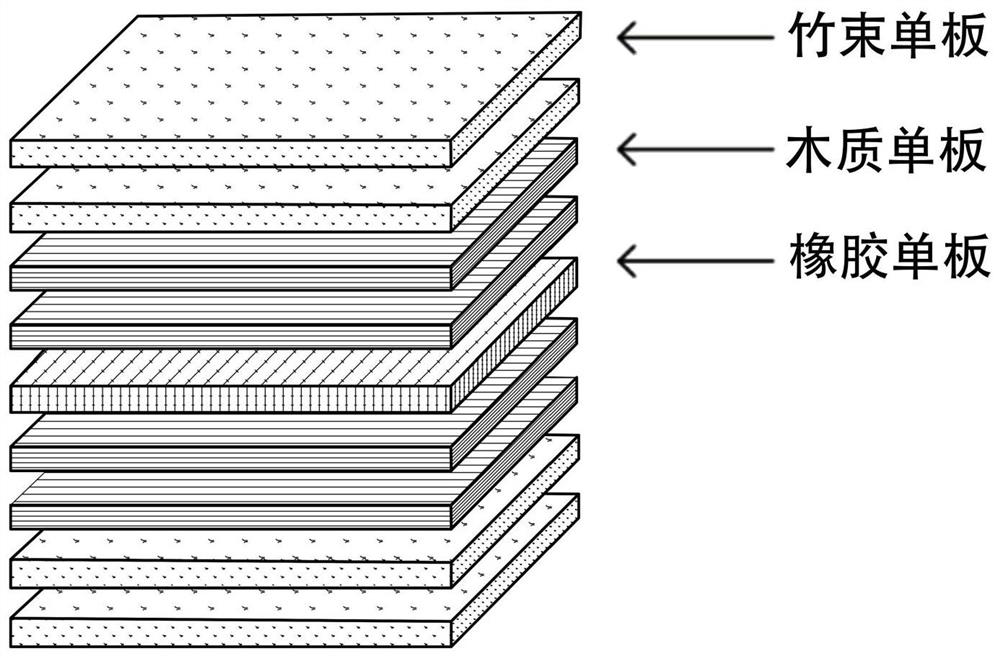

[0043] Apply adhesive on the upper and lower surfaces of the rubber veneer, and adopt the method of symmetrical lamination to form the blank, with the bamboo veneer as the surface layer, the wooden veneer as the middle layer, and the rubber veneer as the core layer, pave the obtained slab Hot pressing is carried out to obtain an impact-resistant bamboo bundle-rubber composite board.

[0044] In the present invention, the adhesive is coated on the upper and lower surfaces of the rubber veneer. In the present invention, the adhesive is preferably a one-component isocyanate adhesive, and in an embodiment of the present invention, the model of the one-component isocyanate adhesive is WANNATECW20; the double-sided sizing amount of the adhesive is preferably 30-50g / m 2 , more preferably ...

Embodiment 1

[0056] Cut the original bamboo into long bamboo sections of equal length, divide the bamboo section into four pieces, remove the bamboo partition, select the outer layer of the bamboo tube, and process it into green side bamboo strips with regular cross-sections by using a splitting machine;

[0057] Utilize bamboo material broomification rolling equipment to carry out broomification and loosen 6 times to described green side bamboo strip, form the bamboo bundle fiber unit;

[0058] Immerse the bamboo bundle fiber unit in an aqueous NaOH solution with a mass concentration of 15% for 3 hours, take it out and wash it until neutral, then dry it, and control the moisture content to 10%, to obtain a bamboo bundle unit;

[0059] Adopt braiding machine to carry out integral weaving of described bamboo bundle unit, obtain bamboo bundle veneer (thickness is 4mm);

[0060] Immerse the bamboo bundle veneer in a thermosetting phenolic resin solution with a solid content of 25% for 10 minu...

Embodiment 2

[0065] Prepare bamboo beam veneer (thickness is 4mm) according to the method for embodiment 1;

[0066] Immerse the bamboo bundle veneer in a thermosetting phenolic resin solution with a solid content of 25% for 10 minutes, take it out and drain it, and then expose it to sunlight until the water content is 10%, and set aside, the amount of gluing is 20% (mass content), Get the treated bamboo bundle veneer;

[0067]Immerse the poplar veneer (thickness 2mm) in a thermosetting phenolic resin solution with a solid content of 25% for 10 minutes, take it out and drain it, and expose it to sunlight until the water content is 10%. content), to obtain the treated wood veneer;

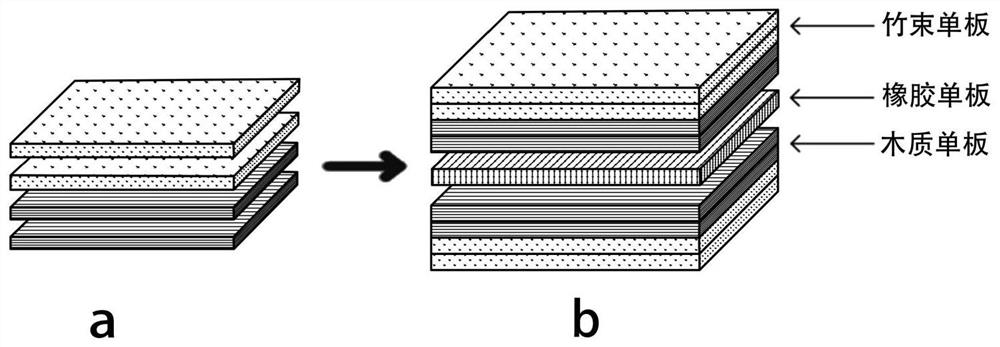

[0068] according to figure 2 In the method shown in middle a, two layers of above-mentioned treated bamboo veneers and two layers of treated poplar veneers are respectively assembled into blanks, and the paved slabs are sent into a multi-layer hot press to control the slabs. Thickness is 6mm, hot-pressing co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com