Preparation method of high-strength and high-conductivity Cu-Cr-Zr bar

A technology of copper chromium zirconium and high conductivity, which is applied in the field of copper alloys, can solve the problems that it is difficult to achieve high strength, high conductivity, reduce conductivity, and cannot achieve high strength and high conductivity, so as to achieve high strength, reduce energy consumption, crystal grainy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

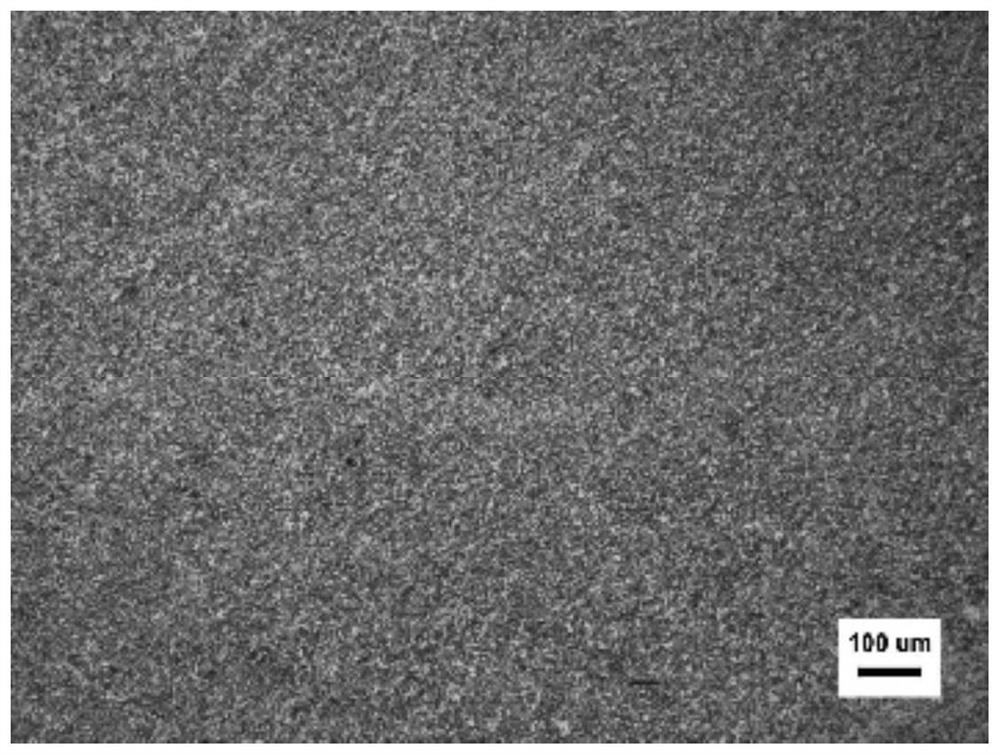

Image

Examples

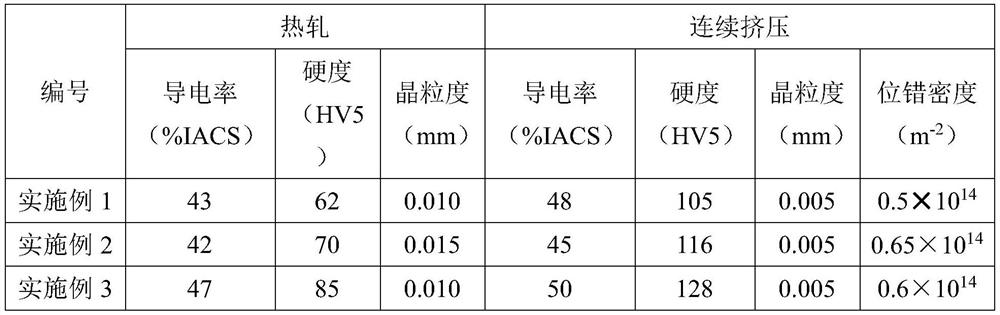

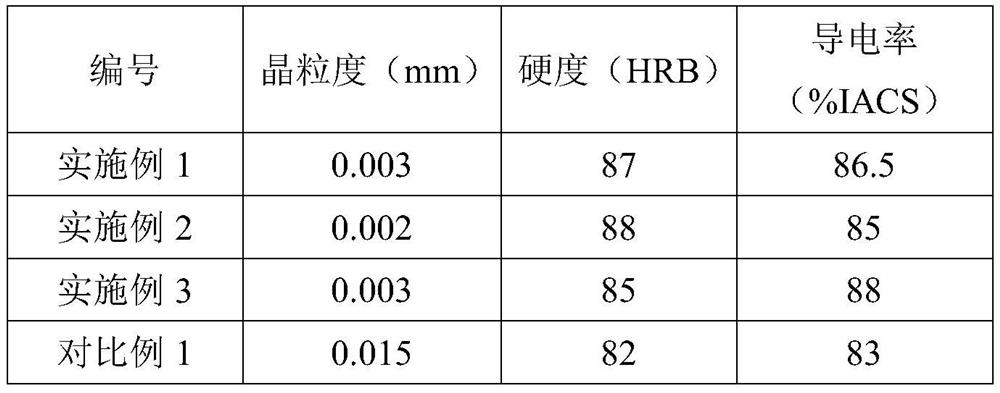

Embodiment 1

[0027] The composition of copper chromium zirconium is: Cr: 0.65wt%, Zr: 0.045wt%, the rest is Cu and unavoidable impurities, and the impurity content is not more than 0.1%; the process flow of copper chromium zirconium rods:

[0028] 1) Casting: the melting temperature is controlled at 1280°C, the cooling water pressure is 0.3MPa, the copper-chromium-zirconium alloy billet diameter is 80mm, the casting speed is 25mm / min, and the billet length is 6m;

[0029] 2) Hot rolling: heat the cast slab with a diameter of 80mm to 990°C, keep it warm for 30 minutes, then continuously roll it to a diameter of 20mm, quench and coil, the total deformation is 93.75%, and the rolling speed is 30m / min;

[0030] 3) pickling: put the hot-rolled billet into the pickling tank for pickling for 15 minutes to remove the surface scale;

[0031] 4) continuous extrusion: the wire billet after pickling is carried out continuous extrusion, extrusion speed is set as 3m / min, extruded into the wire billet th...

Embodiment 2

[0037] The composition of copper chromium zirconium is: Cr: 0.55wt%, Zr: 0.075wt%, the rest is Cu and unavoidable impurities, of which the impurity content is not more than 0.1%; the process flow of copper chromium zirconium rods:

[0038] 1) Casting: the smelting temperature is controlled at 1300°C, the cooling water pressure is 0.3MPa, the copper-chromium-zirconium alloy billet diameter is 50mm, the casting speed is 30mm / min, and the billet length is 7m;

[0039] 2) Hot rolling: heat the casting slab with a diameter of 50mm to 970°C, keep it warm for 20 minutes, then continuously roll it to a diameter of 15mm, quench and coil, the total deformation is 91%, and the rolling speed is 40m / min;

[0040]3) pickling: put the hot-rolled billet into the pickling tank for pickling for 15 minutes to remove the surface scale;

[0041] 4) Continuous extrusion: the pickled wire billet is continuously extruded, the extrusion speed is set at 5m / min, and extruded into a wire billet with a di...

Embodiment 3

[0047] The composition of copper chromium zirconium is: Cr: 0.95wt%, Zr: 0.075wt%, the rest is Cu and unavoidable impurities, of which the impurity content is not more than 0.1%; the process flow of copper chromium zirconium rods:

[0048] 1) Casting: The smelting temperature is controlled at 1350°C, the cooling water pressure is 0.3MPa, the copper-chromium-zirconium alloy billet diameter is 60mm, the casting speed is 20mm / min, and the billet length is 6m;

[0049] 2) Hot rolling: heat the casting slab with a diameter of 60mm to 960°C, keep it warm for 60 minutes, and then continuously roll it to a diameter of 25mm for quenching and winding, the total deformation is 82.64%, and the rolling speed is 35m / min;

[0050] 3) pickling: put the hot-rolled billet into the pickling tank for pickling for 15 minutes to remove the surface scale;

[0051] 4) Continuous extrusion: the pickled wire billet is continuously extruded, the extrusion speed is set at 2.5m / min, and the diameter is ex...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com