Cobalt complex, method for manufacturing same, and method for manufacturing cobalt-containing thin film

A technology of cobalt complexes and meanings, applied in cobalt organic compounds, chemical instruments and methods, compounds of group 4/14 elements of the periodic table, etc., can solve problems such as poor conduction of transistors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

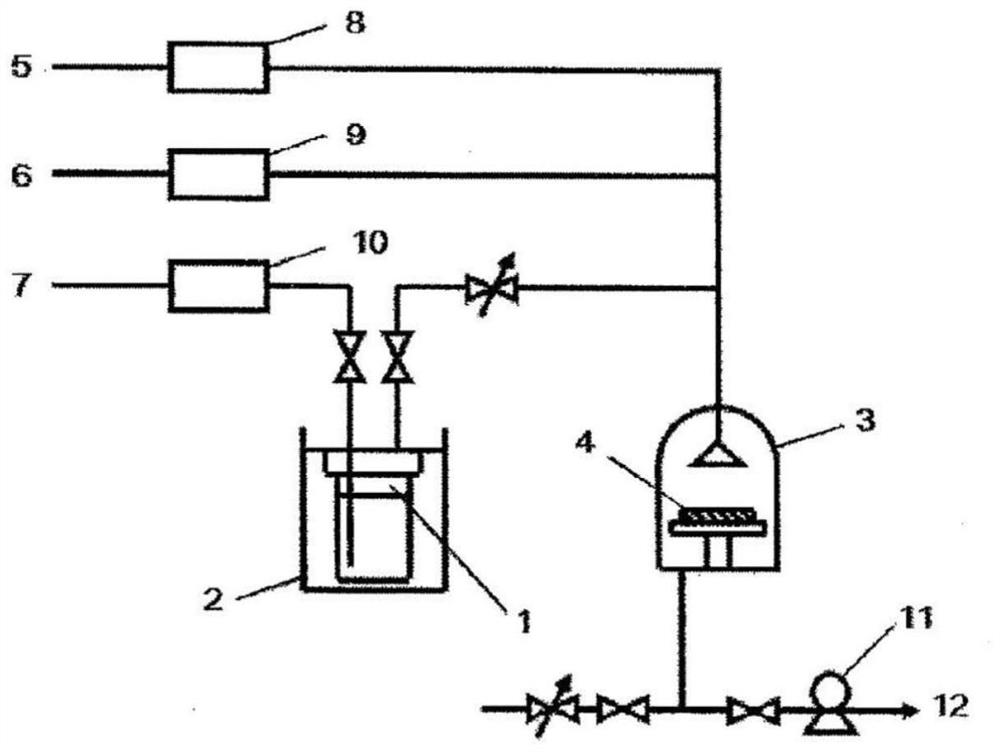

Method used

Image

Examples

Embodiment

[0200] Hereinafter, the present invention will be described in more detail with reference to examples, but the present invention is not limited thereto. Production of the compounds described in Reference Examples 1 to 7 and Examples 1 to 7, 12, and 16 was all carried out under an argon atmosphere. THF, diethyl ether, and hexane used were dehydrated products manufactured by Kanto Chemical Co., Ltd. 2-Dimethylamino-1,1-dimethylethylamine and 2-diethylamino-1,1-dimethylethylamine were synthesized according to the method described in JP 2018-507255 A.

reference example 1

[0202] [chemical formula 39]

[0203]

[0204]Add 36.0 mL (1.6 mol / L, 57.6 mmol) of butyl lithium in hexane to a solution of 7.62 g (52.4 mmol) of (tert-butyl) (trimethylsilyl) amine in ether (60 mL) at 0°C ). After stirring the mixture at 25°C for 2 hours, a suspension of 3.40 g (26.2 mmol) of cobalt chloride in diethyl ether (30 mL) was added at -78°C. After stirring the mixture at 25°C for 18 hours, the solvent was distilled off under reduced pressure. 60 mL of hexane was added to the residue, followed by vigorous stirring at room temperature. After filtering the resulting suspension, the solvent was distilled off from the filtrate under reduced pressure. By distilling the remaining liquid (heating temperature 90° C. / back pressure 39 Pa), 2.93 g of bis[(tert-butyl)(trimethylsilyl)amino]cobalt (2- 2) (Yield 32%).

[0205] 1 H-NMR (400MHz, C 6 D. 6 , δ): 54.3 (br, 18H), 33.0 (br, 18H).

reference example 2

[0207] [chemical formula 40]

[0208]

[0209] To a THF (50 mL) solution of 13.0 g (100 mmol) of cobalt chloride was added 154 mL (1.3 mol / L, 200 mmol) of a THF solution of lithium bis(trimethylsilyl)amide at -78°C. After stirring the mixture at 25°C for 17 hours, the solvent was distilled off under reduced pressure. To the residue was added 90 mL of hexane, followed by vigorous stirring at room temperature. After the resulting suspension was filtered, the solvent was distilled off from the filtrate under reduced pressure. By subliming the remaining solid (heating temperature 120° C. / back pressure 51 Pa), 40.1 g of bis[bis(trimethylsilyl)amino]cobalt (2-8) was obtained in the form of a dark green solid (received rate 89%).

[0210] 1 H-NMR (400MHz, C 6 D. 6 , δ): 168.2 (br, 4H), 100.2 (br, 4H), -15.9 (br, 36H).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com