Electro-Fenton-auto-oxidation device for treating microelectronic wastewater and method thereof

A microelectronics and self-oxidation technology, applied in the field of water treatment, can solve the problems of low recycling rate and poor microelectronic wastewater treatment effect, and achieve the effects of reducing the production of iron sludge, reducing the dosage of iron sources, and reducing the concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

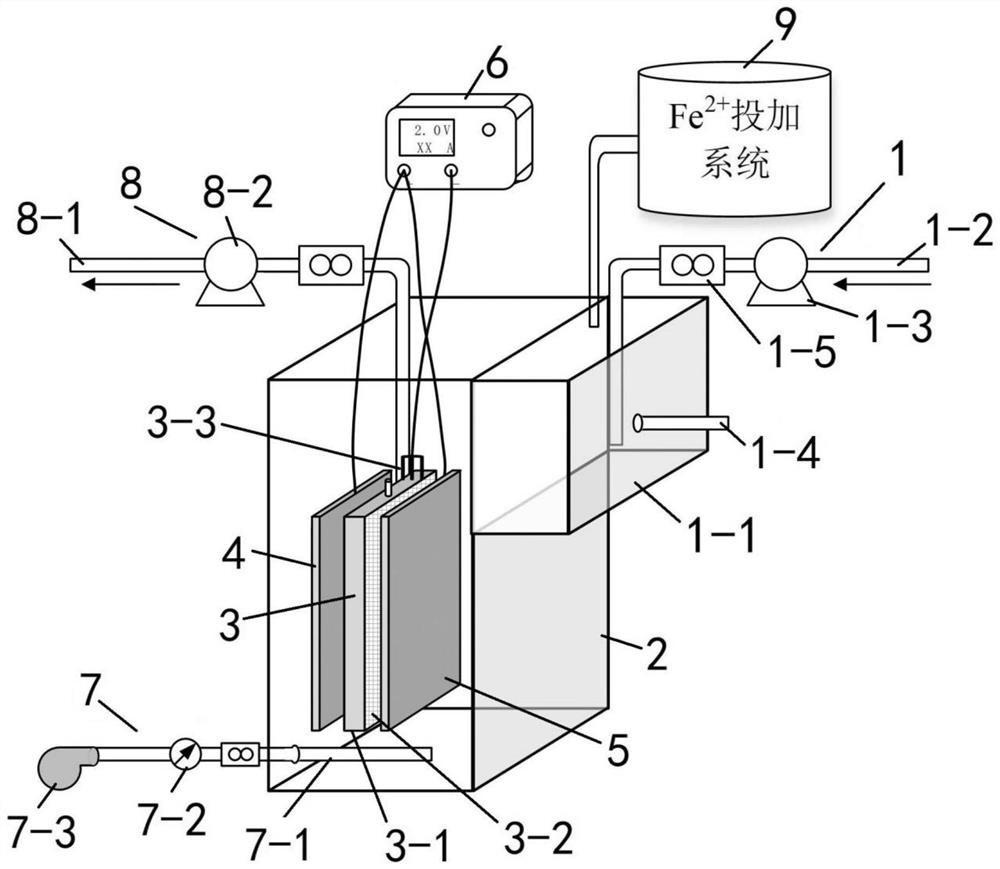

[0032] Such as figure 1 As shown, a kind of electric Fenton-autooxidation device for processing microelectronic waste water provided by the present invention comprises a water inlet system 1, a reactor housing 2, a combined cathode 3 located in the reactor housing 2, The first anode 4, the second anode 5, the DC power supply 6 electrically connected to the combined cathode 3, the first anode 4 and the second anode 5, the aeration system 7 located at the bottom of the reactor shell 2, the water outlet system 8, According to H in the water 2 o 2 Concentration adjustment dosage of Fe 2+ Dosing system 9; the combined cathode 3 includes a membrane frame 3-1 and a stainless steel wire mesh cathode 3-2, and the membrane frame 3-1 is provided with a suction port 3-3 communicating with the inner chamber of the membrane frame 3-1, The suction port 3-3 is connected to the water outlet pipe 8-1 of the water outlet system 8;

[0033] The stainless steel wire mesh cathode 3-2 is arrange...

Embodiment 2

[0041] This embodiment provides the device provided in Embodiment 1 to treat the electric Fenton-autooxidation method of microelectronic wastewater, comprising the following steps:

[0042] 1) The microelectronic wastewater first enters the water inlet tank 1-1 through the water inlet pipe 1-2, and the flow meter 1-5 monitors the flow rate in the water inlet;

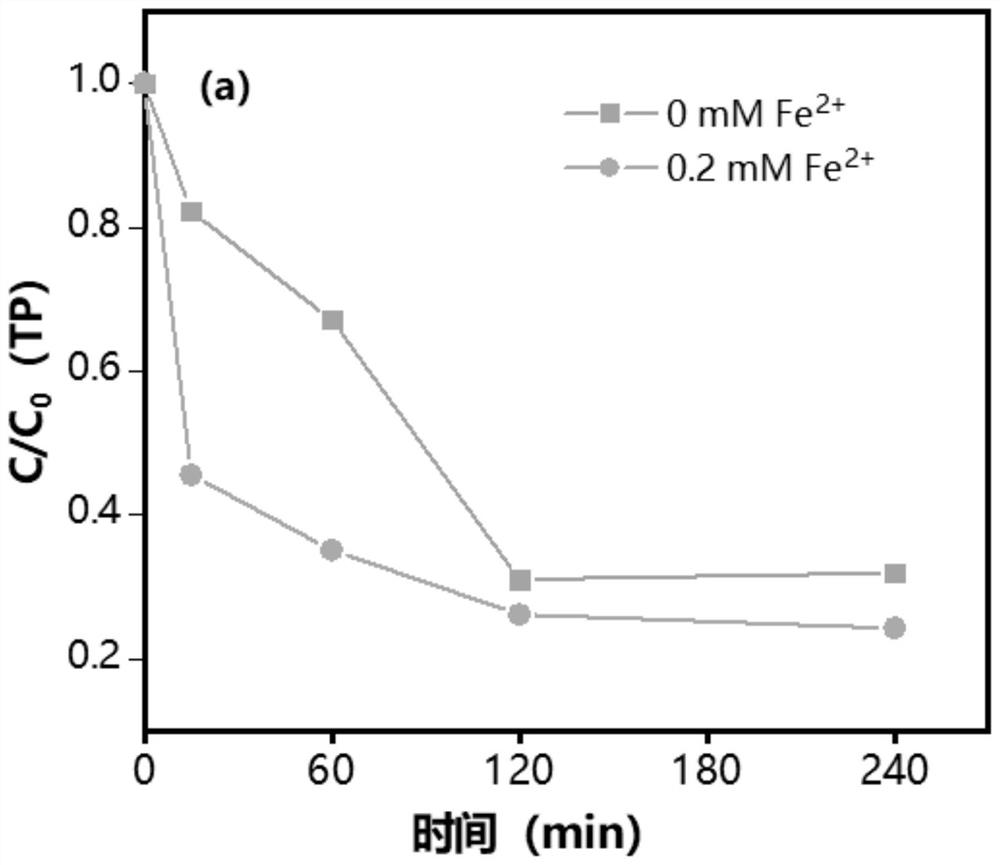

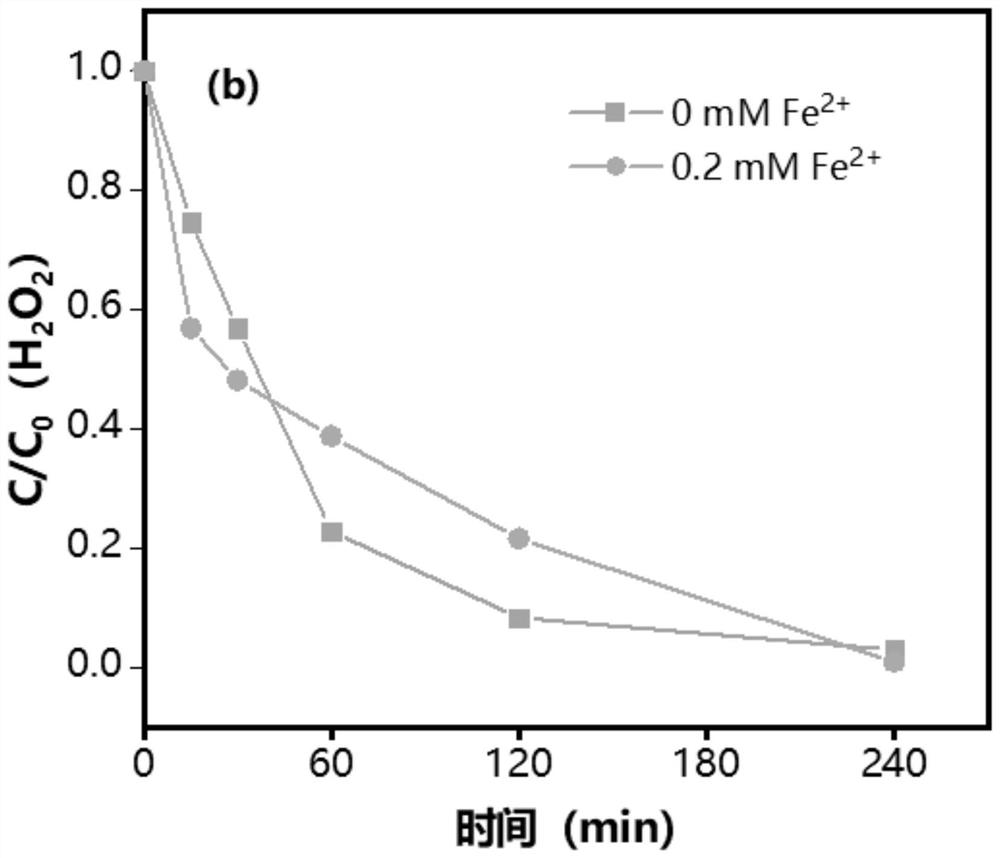

[0043] 2) detect H in the device by manual monitoring or a portable detector 2 o 2 Concentration, when influent H 2 o 2 When the concentration is too high, open the aeration system 7 and control the Fe 2+ Dosing system 9 dosing iron source, the H contained in the microelectronics wastewater 2 o 2 On the one hand, it can be removed through the decomposition reaction between the interface of the combined cathode 3, the first anode 4 and the second anode 5 and the decomposition reaction in the homogeneous system formed in the reactor shell 2, while the original H in the influent 2 o 2 Fe capable of interfacing with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com