Micro-foaming polyamide magnetic plastic based on organic fluorine modification and preparation method of micro-foaming polyamide magnetic plastic

A fluorine-modified and micro-foaming technology, which is applied in the field of micro-foamed polyamide magnetic plastics and its preparation, can solve the problems of large size changes, poor surface quality, and reduced mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

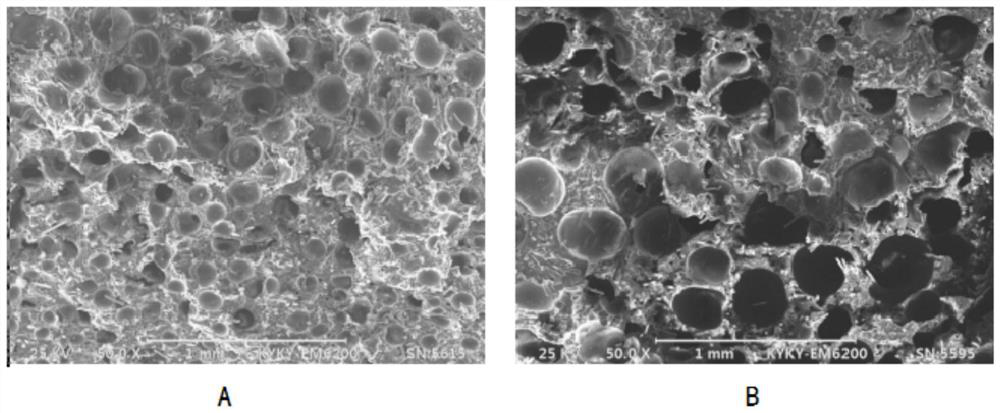

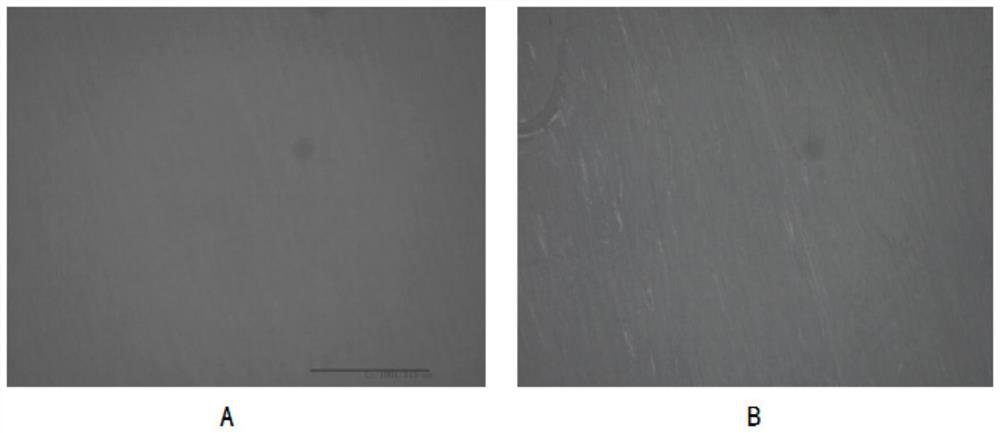

Image

Examples

Embodiment 1

[0029] A micro-foamed polyamide magnetic plastic based on organic fluorine modification. The magnetic plastic is made of basic raw materials and added raw materials. The basic raw materials are composed of the following raw material components in mass percentages: PA resin 70%, pro-CO 2 10% additives, 10% phenolic hydroxyl resin, 10% fillers, the added raw materials include the following components: compatibilizer, nucleating agent, foaming agent and other additives, the mass percentage of each added raw material component and the basic raw material The proportions are: compatibilizer 0.05%, nucleating agent 0.01%, foaming agent 0.05%, and other additives 0.02%.

[0030] Among them, the PA resin is PA6; pro-CO 2 The additive is tetrafluoroethylene-hexafluoropropylene copolymer; the phenolic hydroxyl resin is general-purpose phenolic resin; the filler is ferrite magnetic powder; the compatibilizer is maleic anhydride graft compatibilizer; the nucleating agent is silicon oxide; ...

Embodiment 2

[0038] A micro-foamed polyamide magnetic plastic based on organic fluorine modification. The magnetic plastic is made of basic raw materials and added raw materials. The basic raw materials are composed of the following raw material components in mass percentages: PA resin 80%, pro-CO 2 3% additives, 5% phenolic hydroxyl resin, 12% fillers, the added raw materials include the following components: compatibilizer, nucleating agent, foaming agent and other additives, the mass percentage of each added raw material component and the basic raw material The proportions are: compatibilizer 5%, nucleating agent 2%, blowing agent 4%, other additives 2%.

[0039] Among them, the PA resin is PA66; pro-CO 2 The additive is ethylene-chlorotrifluoroethylene copolymer; the phenolic hydroxyl resin is lignin resin; the filler is rare earth permanent magnetic powder; the compatibilizer is maleic anhydride graft compatibilizer; the nucleating agent is sorbitol nucleating agent; The foaming agen...

Embodiment 3

[0047] A micro-foamed polyamide magnetic plastic based on organic fluorine modification. The magnetic plastic is made of basic raw materials and added raw materials. The basic raw materials are composed of the following raw material components in mass percentages: PA resin 60%, pro-CO 2 20% additives, 10% phenolic hydroxyl resin, 10% fillers, the added raw materials include the following components: compatibilizer, nucleating agent, foaming agent and other additives, the mass percentage of each added raw material component and the basic raw material The proportions are: compatibilizer 1.5%, nucleating agent 0.08%, foaming agent 1%, and other additives 1.5%.

[0048] Among them, PA resin is branched PA; pro-CO 2 The additive is polyvinylidene fluoride; the phenolic hydroxyl resin is bisphenol A type boron phenolic resin; the filler is metal oxide; the compatibilizer is maleic anhydride graft compatibilizer; the nucleating agent is rosin nucleating agent; Foaming agent is carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com