Composite raw material for female private care solution and preparation method thereof

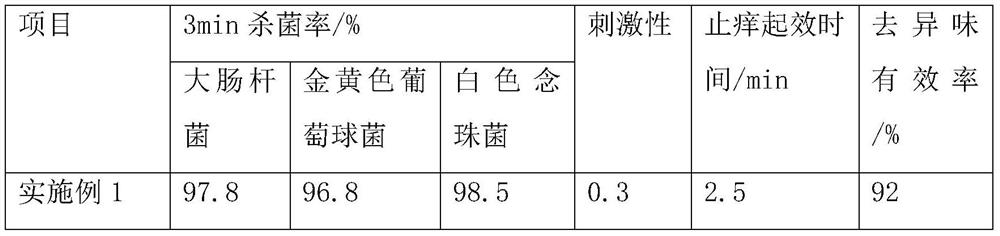

A nursing solution and intimate technology, which is applied in the field of compound raw materials for female intimate nursing solutions and its preparation, can solve the problems of high irritation, slow sterilization and antipruritic effects, etc., and achieve fast antibacterial speed, accelerated sterilization and antipruritic speed, The effect of eliminating odor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

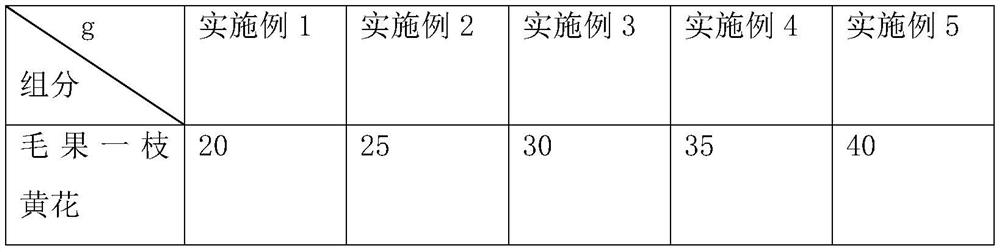

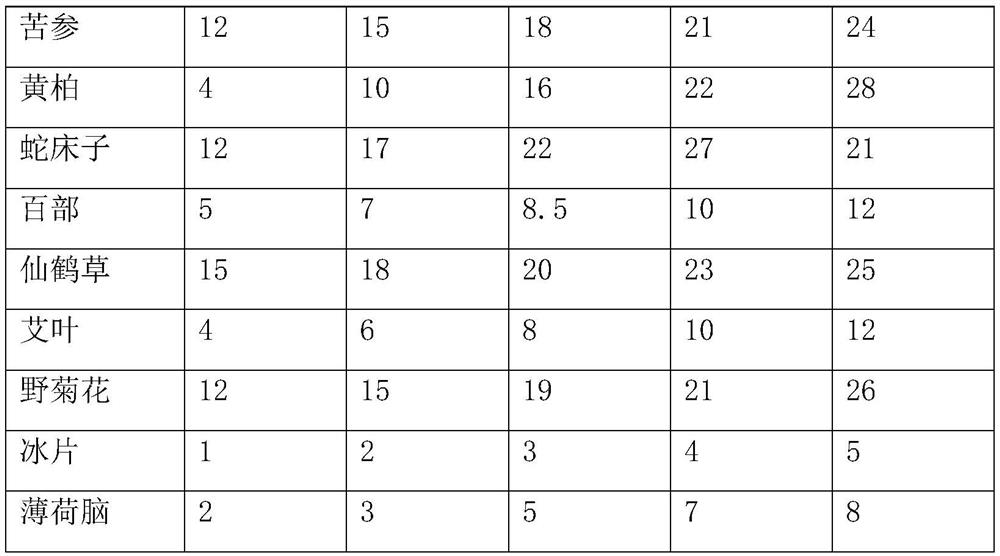

Examples

preparation example 1-7

[0039] Corn starch was selected from Foshan Daping Chemical Technology Co., Ltd., model 049; chitosan was selected from Qingdao Haiweisen Biotechnology Co., Ltd., model 00123; nepeta powder was selected from Xi’an Tianrui Biotechnology Co., Ltd., the specification was 10:1, the model is powder; nano-diatomaceous earth is selected from Guangzhou Yikang New Material Technology Co., Ltd., the model is 1150#, the mesh number is 325 mesh, and the shell powder is selected from Lingshou County Jianhui Mineral Products Processing Factory, the model is JH-05, the number of meshes is 400 meshes, and the epoxy resin emulsion is selected from Shandong Moore Chemical Co., Ltd., and the model is EP-51.

preparation example 1

[0040] Preparation Example 1: (1) Dissolve 30g of cornstarch in 1000g of water, and dissolve 30g of chitosan in 1000g of glacial acetic acid with a concentration of 1.5%, mix the two solutions at a mass ratio of 1:0.9, and paste at 90°C After 1h, add 40g nepeta powder and mix well to prepare a film preparation; (2) stir 10g shell powder and 10g nano-diatomaceous earth at a speed of 500r / min, and mix them while stirring at a speed of 500r / min. The membrane preparation is sprayed on the shell powder and nano-diatomite, and after hot-air drying, the shell powder and nano-diatomite are soaked in 1000g of 2% sodium hydroxide for 30 minutes, washed with water, and then dried. The hot-air drying temperature is 50°C , the time is 30min, and the drying temperature after washing is 60°C, and the time is 20min.

preparation example 2

[0041] Preparation Example 2: (1) Dissolve 35g of cornstarch in 1150g of water, dissolve 35g of chitosan in 1150g of 1.5% glacial acetic acid, mix the two solutions at a mass ratio of 1:1, and paste at 95°C After 0.5h, add 50g nepeta powder and mix well to prepare a film preparation; (2) stir 15g shell powder and 15g nano-diatomite at a speed of 600r / min, and stir while stirring at a speed of 600r / min. Spray the film preparation on the shell powder and nano-diatomite, after hot-air drying, soak the shell powder and nano-diatomite in 1200g of 4% sodium hydroxide for 40min, wash with water, and dry at a temperature of 55°C. ℃, the time is 25 minutes, and the drying temperature after washing is 55 ℃, and the time is 25 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com