Chitosan-based polyelectrolyte composite hemostatic sponge, preparation method and application

A technology of chitosan-based polymerization and hemostatic sponge, applied in the application, pharmaceutical formulation, surgical adhesive and other directions, can solve the problems of undiscovered patent publications, etc., and achieve the advantages of large-scale quantitative production, good hemostatic effect, and prevention of wound infection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The preparation method of the above-mentioned chitosan-based polyelectrolyte composite hemostatic sponge, the steps are as follows:

[0037] (1) Preparation of chitosan-sodium alginate polyelectrolyte complex;

[0038] ⑵Preparation of chitosan-based polyelectrolyte composite hemostatic sponge.

[0039] Preferably, said step (1) specifically includes the following steps:

[0040] Get chitosan and join in deionized water, add the acetic acid solution that volume percent is 1% again, stir until chitosan is all dissolved, be mixed with the chitosan solution of 2% (w / v); Dissolve sodium in deionized water and prepare 2% (w / v) sodium alginate solution; mix and stir the prepared chitosan solution and sodium alginate solution at a volume ratio of 1:10 to 10:1 Uniform, that is, polyelectrolyte complexes with different proportions.

[0041] Preferably, said step (2) specifically includes the following steps:

[0042] Take genipin and dissolve it in deionized water to prepare ...

Embodiment 1

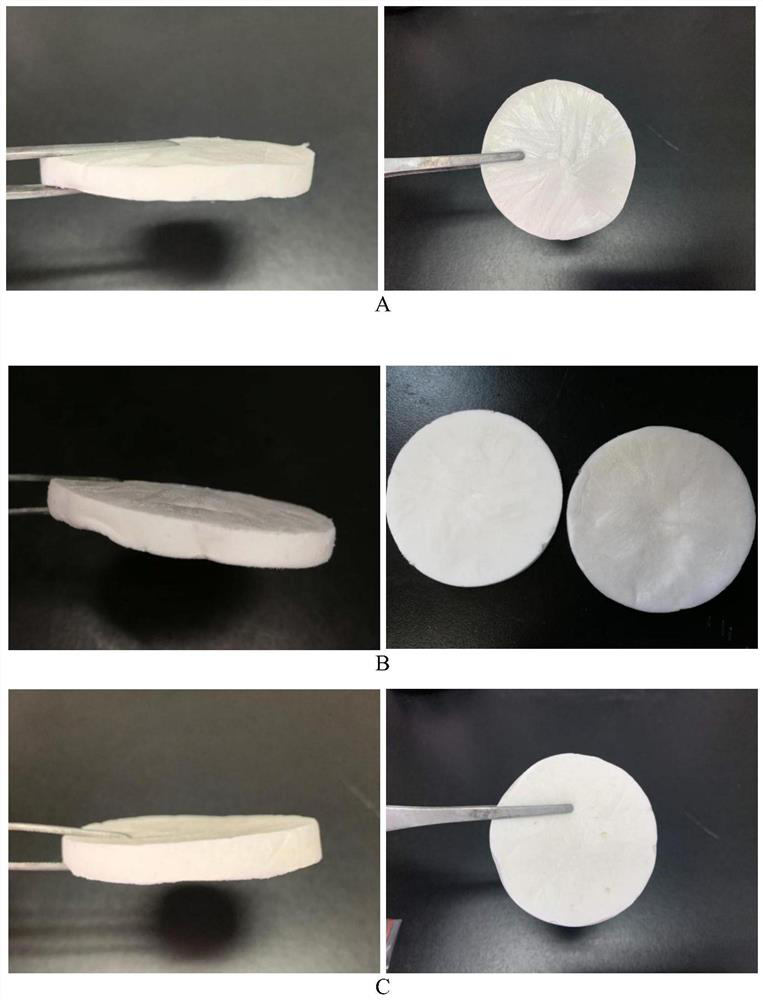

[0045] Embodiment 1: Preparation of chitosan-based polyelectrolyte composite hemostatic sponge

[0046] specific method:

[0047] (1) Get described chitosan and join in deionized water, then add volume percent and be 1% acetic acid solution, stir until chitosan is all dissolved, be mixed with 2% (w / v) chitosan solution; get the same sodium alginate and dissolve it in deionized water to prepare 2% (w / v) sodium alginate solution; prepare chitosan solution and sodium alginate solution at a ratio of 1:3 , 2:3, 1:1 volume ratio and mix well to obtain polyelectrolyte complexes in different proportions.

[0048] (2) Take the genipin and make it dissolve in deionized water to prepare 0.05% genipin aqueous solution; also take the hyaluronic acid and make it dissolve in deionized water to prepare 1% hyaluronic acid solution; the prepared genipin solution (M CS :M Ge =1:5) and hyaluronic acid solution (M CS :M HA =2:1) Add in the polyelectrolyte complex obtained in step (1), use ...

Embodiment 2

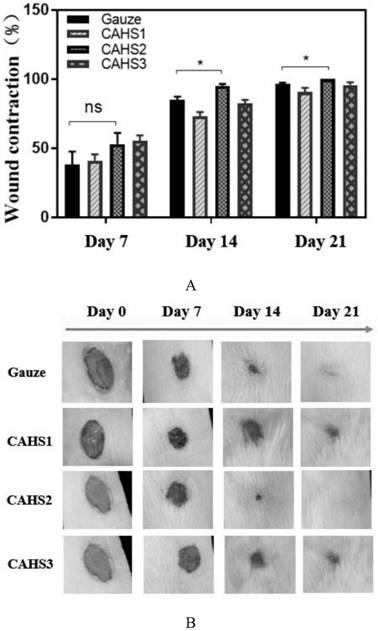

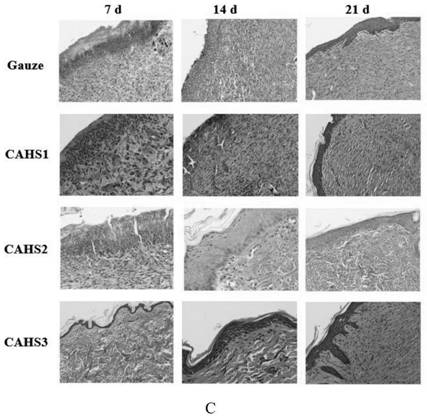

[0049] Example 2: Observation of the microscopic morphology of the composite hemostatic sponge prepared in Example 1

[0050] The microscopic morphology of the composite sponges with three different component ratios was observed by scanning electron microscopy (SEM). Such as figure 2 Shown are the surface and cross-sectional microscopic morphology diagrams of CAHS1, CAHS2, and CAHS3 prepared in Example 1 at 400 times. It can be seen from the figure that all three materials can form a structure with certain pores, and the surface and cross section are almost the same, which proves that the surface and interior of the material are relatively uniform. In comparison, the surface and cross-section of CAHS2 are obviously more uniform than CAHS1 and CAHS3, and have a finer and denser pore-like structure, which plays a vital role in the absorption of body fluids and blood at the wound, and also to a certain extent. affect the mechanical properties of the material. The structures o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com