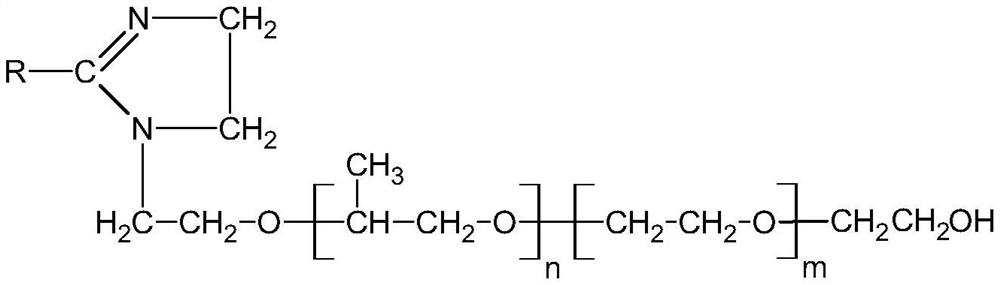

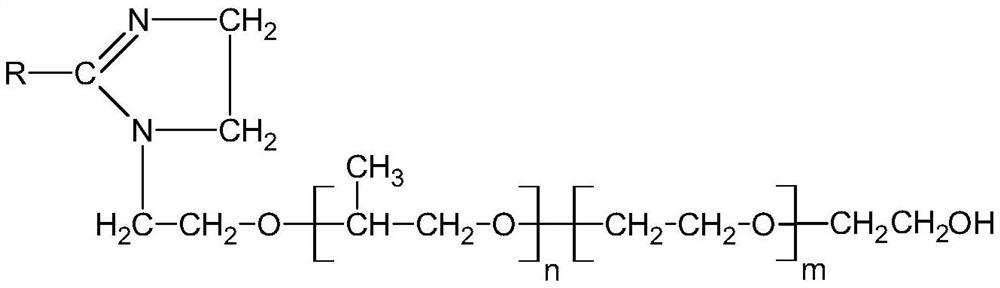

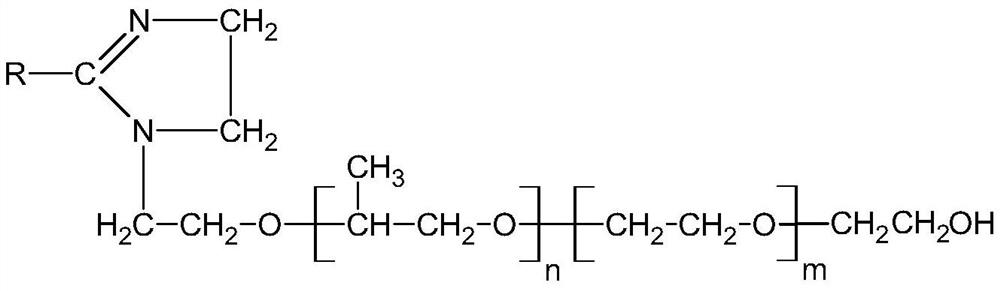

Efficient alkoxylated imidazoline derivative corrosion inhibitor as well as preparation method and application thereof

A technology of chemical imidazoline and rust inhibitor, which is applied in the field of preparation of high-efficiency alkoxylated imidazoline derivative rust inhibitor, can solve problems such as environmental and health damage, nitrite toxicity, and weak rust inhibitory effect, and achieve Increase steric resistance, prevent slump loss, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The present invention also provides a method for preparing a high-efficiency alkoxylated imidazoline derivative rust inhibitor, comprising the following steps

[0018] (1) Mix the fatty acid containing 16 to 20 carbon atoms and hydroxyethylethylenediamine into the reaction kettle, and add xylene as a water carrier, dehydrate and stir the reaction at a certain temperature, and decompress after the reaction Remove xylene to obtain imidazoline derivative intermediate;

[0019] (2) Take a certain amount of imidazoline derivative intermediate into an autoclave, add a certain amount of propylene oxide first under high pressure and a certain temperature, then add a certain amount of ethylene oxide, and obtain the final product after aging.

[0020] The fatty acid is one of hexadecadienoic acid, oleic acid or linoleic acid, linolenic acid, octadecadienoic acid, eicosatrienoic acid or eicosapentaenoic acid. Fatty acid and hydroxyethylethylenediamine are mixed according to the m...

Embodiment 1

[0023] (1) Mix 0.5mol oleic acid with 0.525mol hydroxyethylethylenediamine, add 75g of xylene, react and dehydrate at 160-180°C until the water output is 0.45-0.5mol water, then heat up to 210-230°C for reaction Dehydration until the water yield is 0.45-0.5 mol of water, and xylene is removed under reduced pressure after the reaction is completed.

[0024] (2) Take 0.5 mol of the imidazoline derivative intermediate into the autoclave, first add 0.5 mol of propylene oxide, then add 25 mol of ethylene oxide, and obtain the final product after aging.

[0025] (3) The prepared saturated Ca(OH) containing 1.15% NaCl 2 Pour the solution into three glass ground-mouth bottles, add 0.3% of the above-mentioned rust inhibitor, put a steel bar into the solution, and close the bottle cap tightly. Use a voltmeter to measure the natural potential of the steel bar at 1d, 3d, 5d, and 7d respectively, and compare it with the blank.

Embodiment 2

[0027] (1) Mix 0.5mol linoleic acid with 0.54mol hydroxyethylethylenediamine, add 82g of xylene, react and dehydrate at 160-180°C until the water output is 0.45-0.5mol water, and then heat up to 210-230°C The reaction is dehydrated until the water output is 0.45-0.5mol water, and the xylene is removed under reduced pressure after the reaction is completed.

[0028] (2) Take 0.5 mol of the imidazoline derivative intermediate into the autoclave, first add 1 mol of propylene oxide, then add 30 mol of ethylene oxide, and obtain the final product after aging.

[0029] (3) The prepared saturated Ca(OH) containing 1.15% NaCl 2 Pour the solution into three glass grinding bottles, add 0.6% of the above-mentioned rust inhibitor, put a steel bar into the solution, and close the bottle cap tightly. Use a voltmeter to measure the natural potential of the steel bar at 1d, 3d, 5d, and 7d respectively, and compare it with the blank.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com