Method for synthesizing benserazide hydrochloride by utilizing fixed bed hydrogenation equipment

A technology of benserazide hydrochloride and fixed bed, which is applied in the field of chemical industry and can solve the problems of product deterioration and large amount of catalyst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

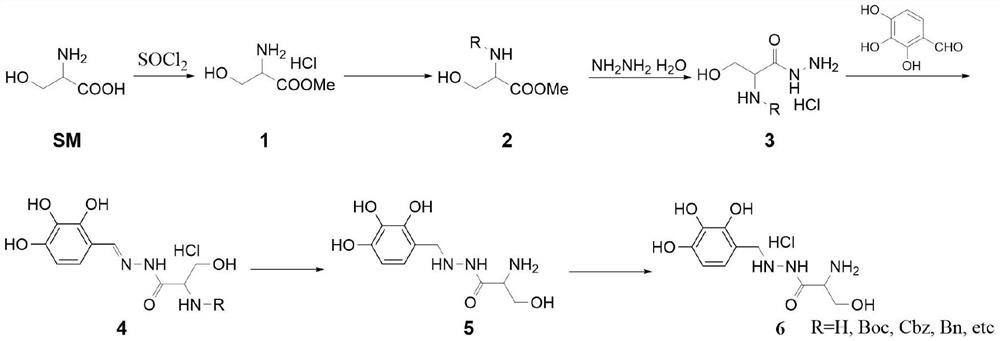

Method used

Image

Examples

Embodiment 1

[0029] This embodiment is a method for synthesizing benserazide hydrochloride using fixed-bed hydrogenation equipment, comprising the following steps:

[0030] S11, the synthesis of compound 1:

[0031] Add 100.0g of serine hydrochloride and 400mL of methanol into a 1L three-necked flask, stir mechanically, and add 135.8g of thionyl chloride dropwise into the system at a temperature below 10°C. During the dropping process, control the temperature of the system Not higher than 20°C. After the dropwise addition, stir and react at a temperature of 80°C for 6 hours. Use TLC (MeOH:EA=4:1) color reagent to detect the complete reaction of the raw materials, stop heating, and wait until the temperature of the reaction system drops to 50°C. After ℃, concentrate under reduced pressure to obtain a white solid crude product, which is beaten with 500 mL n-heptane for 20 min, filtered with suction, rinsed once with 50 mL n-heptane, and dried to obtain compound 1 as a white solid , the yiel...

Embodiment 2

[0043] This embodiment is a method for synthesizing benserazide hydrochloride using fixed-bed hydrogenation equipment, comprising the following steps:

[0044] S21, the synthesis of compound 1:

[0045] Add 100.0g of serine hydrochloride and 400mL of methanol into a 1L three-necked flask, stir mechanically, and add 135.8g of thionyl chloride dropwise into the system at a temperature below 10°C. During the dropping process, control the temperature of the system Not higher than 20°C. After the dropwise addition, stir and react at a temperature of 80°C for 6 hours. Use TLC (MeOH:EA=4:1) color reagent to detect the complete reaction of the raw materials, stop heating, and wait until the temperature of the reaction system drops to 50°C. After ℃, concentrate under reduced pressure to obtain a white solid crude product, which is beaten with 500 mL n-heptane for 20 min, filtered with suction, rinsed once with 50 mL n-heptane, and dried to obtain compound 1 as a white solid , the yiel...

Embodiment 3

[0057] This embodiment is a method for synthesizing benserazide hydrochloride using fixed-bed hydrogenation equipment, comprising the following steps:

[0058] S31, the synthesis of compound 1:

[0059] Add 100.0g of serine hydrochloride and 400mL of methanol into a 1L three-necked flask, stir mechanically, and add 135.8g of thionyl chloride dropwise into the system at a temperature below 10°C. During the dropping process, control the temperature of the system Not higher than 20°C. After the dropwise addition, stir and react at a temperature of 80°C for 6 hours. Use TLC (MeOH:EA=4:1) color reagent to detect the complete reaction of the raw materials, stop heating, and wait until the temperature of the reaction system drops to 50°C. After ℃, it was concentrated under reduced pressure to obtain a white solid crude product, which was beaten with 500 mL n-heptane for 20 min, suction filtered, and the filter cake was rinsed once with 50 mL n-heptane, and dried to obtain compound 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com