Transition metal phosphorus sulfide as well as preparation method and application thereof

A phosphide, transition metal technology, applied in the field of electrocatalysis, can solve the problems of poor electrochemical activity and cycle stability of transition metal phosphide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

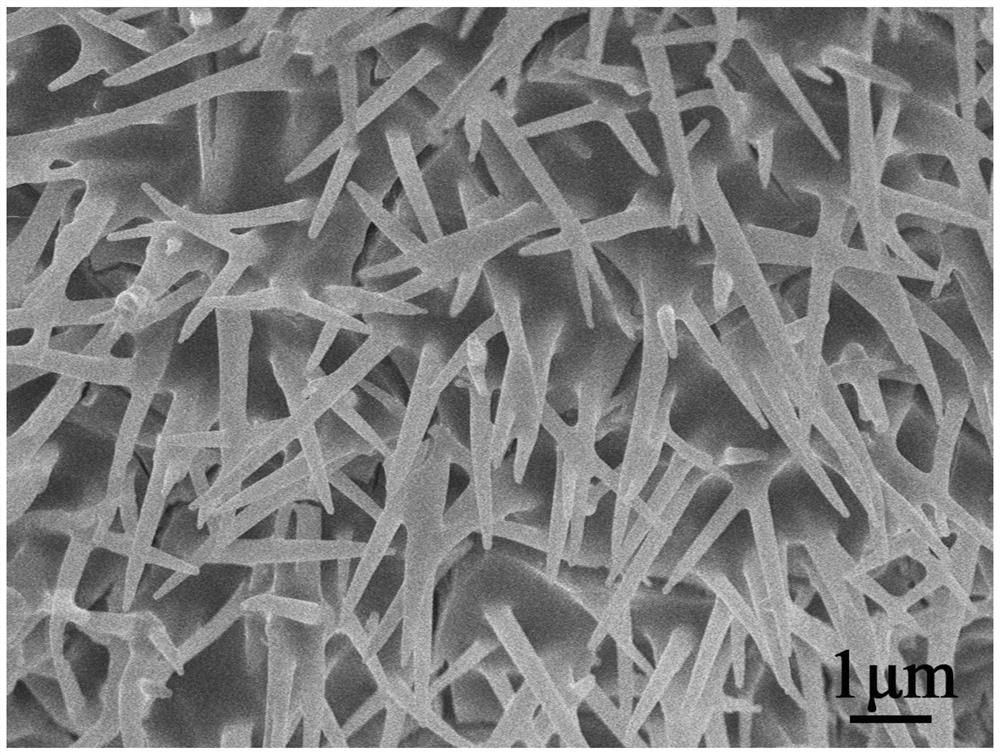

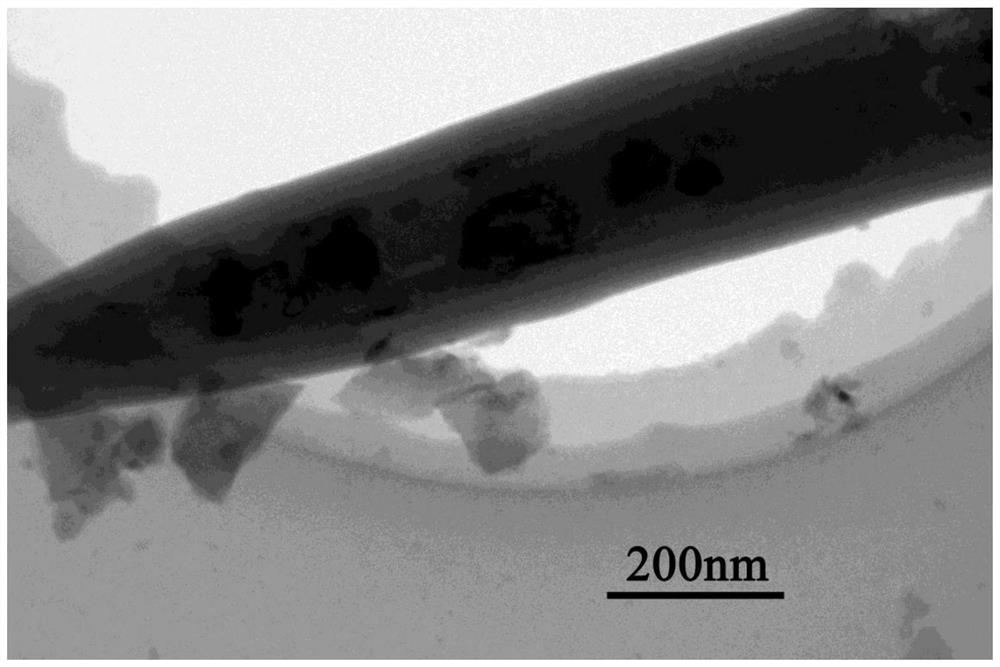

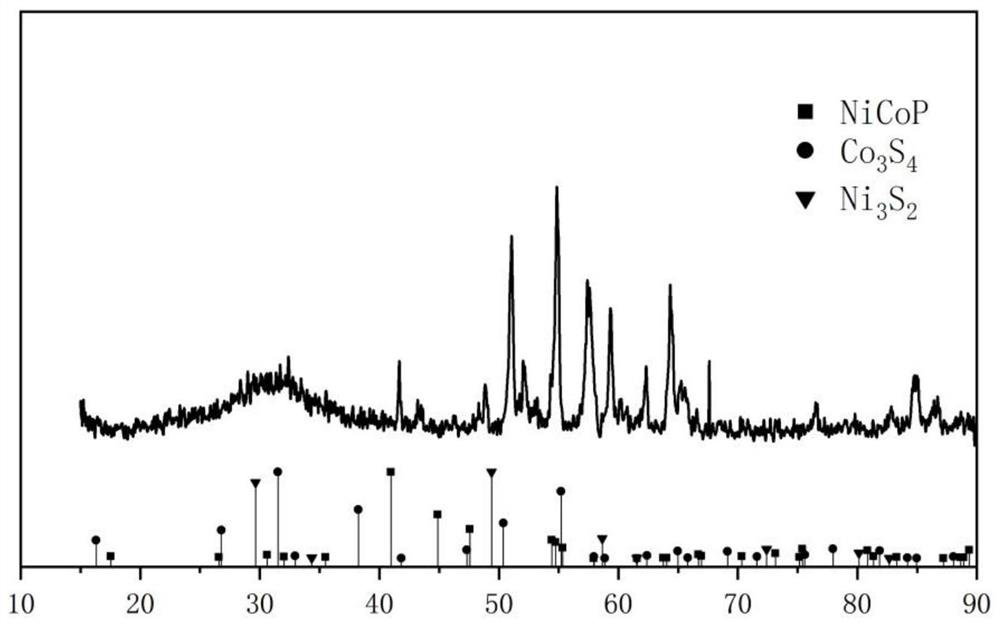

[0029] This embodiment provides a kind of preparation method of transition metal phosphorous sulfide, it comprises the following steps:

[0030] S1, cut 2×2cm 2 Nickel foam, and repeated ultrasonic cleaning of nickel foam with dilute hydrochloric acid and absolute ethanol for 30 minutes in order to remove the nickel oxide layer on the surface to expose a clean outer wall, and then put it in an oven to dry for 12 hours, waiting for use.

[0031] S2. Mix 0.872g nickel nitrate hexahydrate, 0.437g nitric acid hexahydrate, 1.35g urea and 0.037g ammonium fluoride, and add 35mL of deionized water as a solvent to prepare a solution to obtain a precursor solution; The addition of ammonium acts as a morphology inducer.

[0032] S3. After stirring the precursor solution for 30 minutes, pour it into the polytetrafluoroethylene lining, and then put the above-mentioned cleaned foamed nickel into the precursor solution (use polytetrafluoroethylene tape to stick one side to induce its growth...

Embodiment 2

[0035] This embodiment provides a kind of preparation method of transition metal phosphorous sulfide, it comprises the following steps:

[0036] S1, cut 2×2cm 2 Nickel foam, and repeated ultrasonic cleaning of nickel foam with dilute hydrochloric acid and absolute ethanol for 30 minutes in order to remove the nickel oxide layer on the surface to expose a clean outer wall, and then put it in an oven to dry for 12 hours, waiting for use.

[0037] S2. Mix 0.872g nickel nitrate hexahydrate, 0.437g nitric acid hexahydrate, 1.35g urea and 0.037g ammonium fluoride, and add 35mL of deionized water as a solvent to prepare a solution to obtain a precursor solution; The addition of ammonium acts as a morphology inducer.

[0038] S3. After stirring the precursor solution for 30 minutes, pour it into the polytetrafluoroethylene lining, and then put the above-mentioned cleaned foamed nickel into the precursor solution (use polytetrafluoroethylene tape to stick one side to induce its growth...

Embodiment 3

[0041] This embodiment provides a kind of preparation method of transition metal phosphorous sulfide, it comprises the following steps:

[0042] S1, cut 2×2cm 2 Nickel foam, and repeated ultrasonic cleaning of nickel foam with dilute hydrochloric acid and absolute ethanol for 30 minutes in order to remove the nickel oxide layer on the surface to expose a clean outer wall, and then put it in an oven to dry for 12 hours, waiting for use.

[0043] S2. Mix 0.872g nickel nitrate hexahydrate, 0.437g nitric acid hexahydrate, 1.35g urea and 0.037g ammonium fluoride, and add 35mL of deionized water as a solvent to prepare a solution to obtain a precursor solution; The addition of ammonium acts as a morphology inducer.

[0044] S3. After stirring the precursor solution for 30 minutes, pour it into the polytetrafluoroethylene lining, and then put the above-mentioned cleaned foamed nickel into the precursor solution (use polytetrafluoroethylene tape to stick one side to induce its growth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com