Calcination and cooling system for battery material under inert atmosphere and its application method

A battery material and inert atmosphere technology is applied in the field of battery material preparation devices, which can solve the problems that affect the normal process and cycle of battery material preparation, cannot obtain fine crystallinity of crystal grains, and electrode materials are easily oxidized by air, etc., so as to improve energy The effect of utilization, improving final performance, and strengthening the effect of preheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

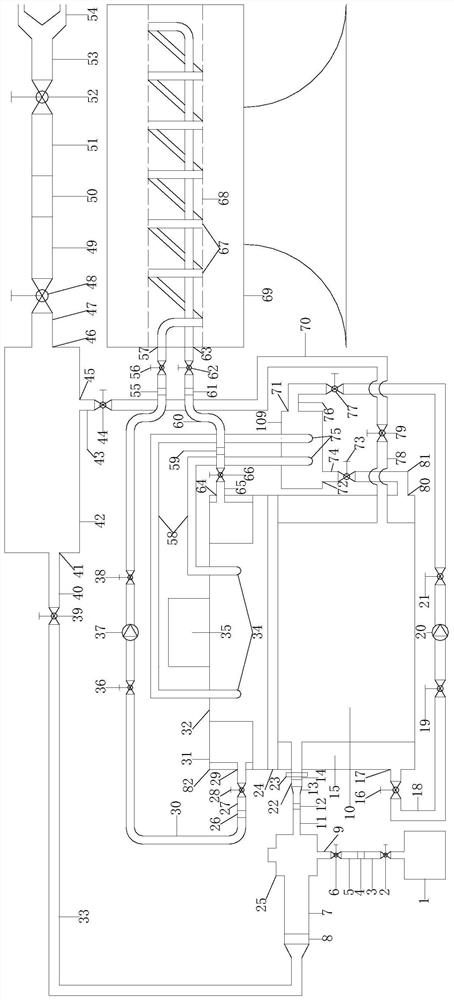

[0062] see figure 1 , which shows a battery material roasting cooling system under an inert atmosphere, the roasting cooling system includes a battery material roasting device and a battery material inert atmosphere cooling device.

[0063] The battery material roasting device includes a tube furnace 69 for roasting the battery material 108, which has an internal roasting area 68 inside. Specifically, the tube furnace 69 is an open tube furnace with dual temperature zones.

[0064] The battery material inert atmosphere cooling device is mainly composed of three parts: a radiation-convection comprehensive cooling and heat recovery device, a semiconductor module thermoelectric power generation device, and an argon preheating and recycling device.

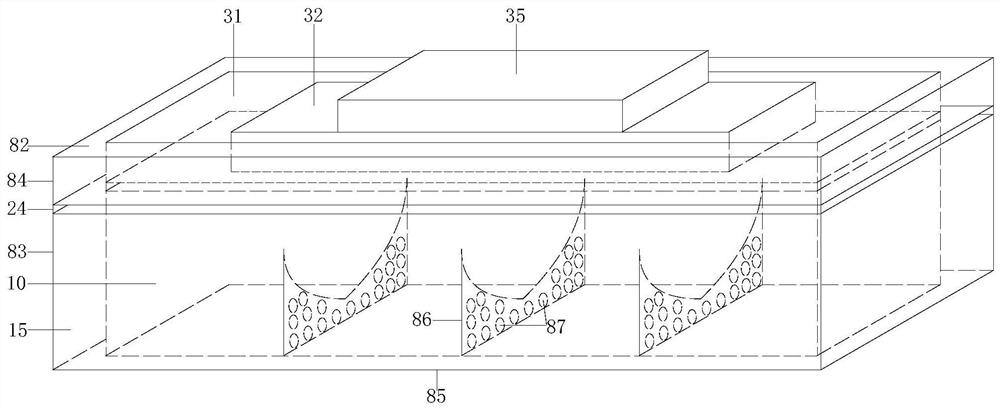

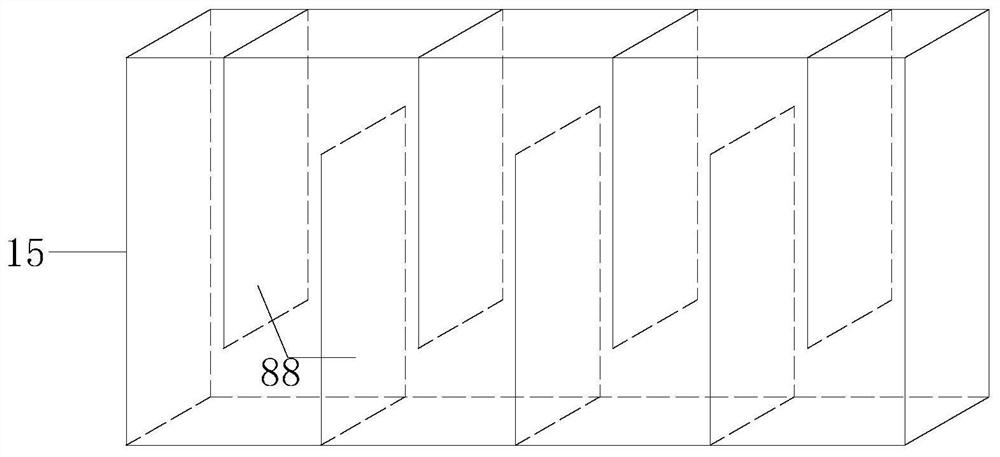

[0065] Radiation-convection comprehensive cooling and heat recovery device is mainly composed of vortex tube cold end 11, cooling chamber 10, water cooling cooling interlayer 15, small cooling water pump 20, heat transfer oil chamber ...

Embodiment 2

[0109] This embodiment is basically the same as Embodiment 1, the main difference is: as Figure 8 As shown, in the present embodiment, the semiconductor thermoelectric power generation module 35 includes: two n-type semiconductors 91 and two p-type semiconductors 92, and the n-type semiconductors 91 and p-type semiconductors 92 are arranged alternately (that is, corresponding to the first one from left to right in the figure). One and the third are p-type semiconductors 92, the second and the fourth are n-type semiconductors 91), and adjacent n-type semiconductors 91 and p-type semiconductors 92 are arranged at intervals; two semiconductor hot end metal plates 90 and three A semiconductor cold-end metal plate 102, a semiconductor hot-end metal plate 90 and a semiconductor cold-end metal plate 102 are respectively located on both sides of the n-type semiconductor 91 and the p-type semiconductor 92, and the adjacent n-type semiconductor 91 and the p-type semiconductor 92 form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com