Foam metal electrode with high catalyst utilization rate and for direct alcohol fuel cell and preparation method of foam metal electrode

A foam metal, fuel cell technology, applied in the direction of fuel cells, battery electrodes, circuits, etc., can solve the problems of low catalyst utilization rate and smooth surface of the support layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

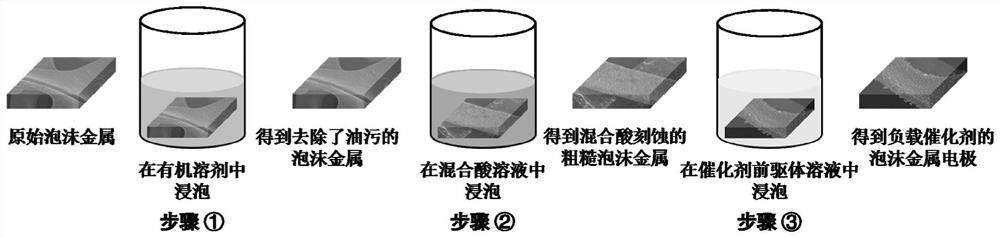

[0024] like figure 1 Shown, the direct alcohol fuel cell foam metal electrode of described high catalyst utilization rate, preparation method comprises the following steps:

[0025] (1) Soak 2 cm* 2 cm nickel foam in acetone solution for 20 minutes and take it out;

[0026] (2) Put it in a mixed acid with glacial acetic acid mass fraction of 50 wt.%, nitric acid mass fraction of 30 wt.%, sulfuric acid mass fraction of 10 wt.% and phosphoric acid mass fraction of 10 wt.%. Soak in the solution for 15 s, take it out, and rinse it with deionized water;

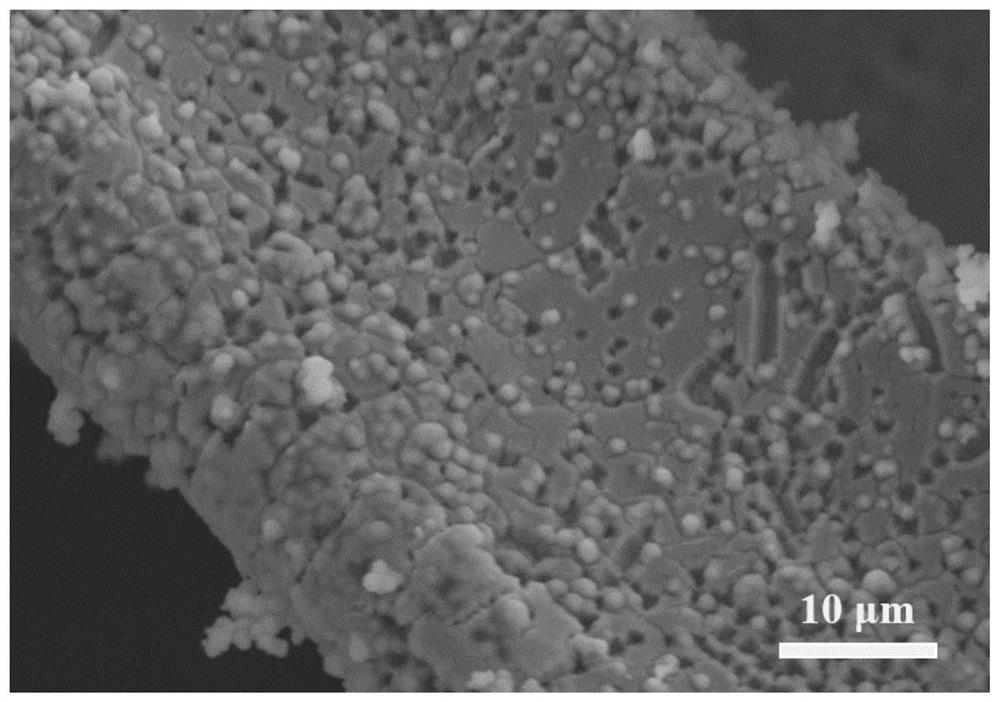

[0027] (3) Put the nickel foam treated with the mixed acid into a solution with a volume of 1.10 mL and a concentration of 15 mmol / L Na 2 PdCl 4 Soak in the solution for 12 h, take it out and dry it at 60°C for 2 h to prepare; the Pd loading on the foamed nickel electrode is 0.35 mg / cm 2 .

[0028] Battery test:

[0029] The prepared foam metal electrode and commercial carbon paper electrode were respectively placed on both ...

Embodiment 2

[0031] A direct alcohol fuel cell foam metal electrode with high catalyst utilization, the preparation method comprising the following steps:

[0032] (1) Soak 3 cm* 3 cm copper foam in isopropanone solution for 60 min, then take it out;

[0033] (2) Put it in a mixed acid with glacial acetic acid mass fraction of 60 wt.%, nitric acid mass fraction of 25 wt.%, sulfuric acid mass fraction of 5 wt.% and phosphoric acid mass fraction of 10 wt.%. Soak in the solution for 60 s, take it out, and rinse it with deionized water;

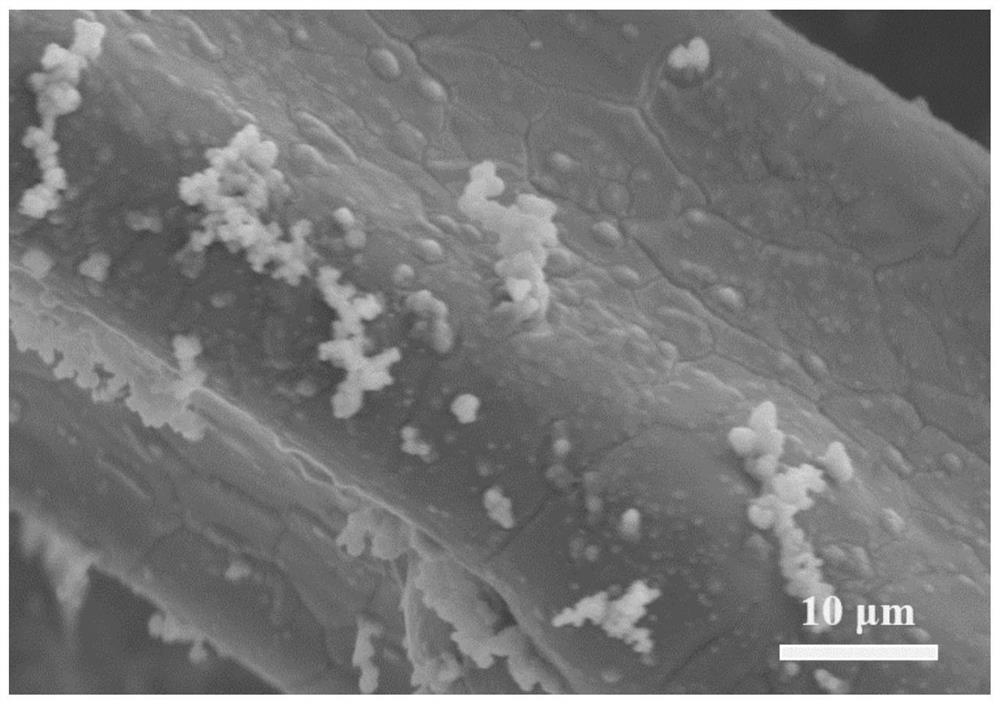

[0034] (3) Put the mixed acid-treated copper foam in a volume of 1.73 mL and a concentration of 50 mmol / L K 2 PtCl 6 Soak in the solution for 2 hours, take it out and dry it at 80°C for 6 hours to prepare; wherein, the Pt loading on the foamed nickel electrode is 1.5mg / cm 2 .

[0035] Battery test:

[0036] The anode supplies a mixture of 3 mol / L methanol and 3 mol / L potassium hydroxide, and other battery test parameters are the same as in Example 1. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com