Aluminum nitride powder and preparation method thereof

An aluminum nitride and powder technology, applied in the field of aluminum nitride powder and its preparation, can solve the problems of unsatisfactory anti-hydrolysis and anti-oxidation properties, large particle size of aluminum nitride and high energy consumption, and achieve excellent hydrolysis resistance. and antioxidant properties, uniform particle size distribution, and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh 150g of alumina powder and 1.76kg of monocrystalline sugar C at the same time 6 (H 2 O) 6 . The two were added to 3.3kg of distilled water and mixed thoroughly. Put the stirred reaction raw materials into the tray, and set the heating temperature and holding time curve. The heating temperature of the first section is set at 90° C., and the holding time is 18 hours. The heating temperature of the second stage is 125° C., and the holding time is 4 hours. The heating temperature of the third section is 170°C, and the holding time is 17h. The heating temperature of the fourth section is 190°C, and the holding time is 17h. The heating temperature in the fifth section is 210°C, and the holding time is 17h. The heat-treated raw materials are put into a reaction furnace for sintering, and the atmosphere is 20% hydrogen and 80% nitrogen. The gas flow rate is 4m 3 / h. After 17 hours, the reaction temperature rose to 1250°C, and the reaction temperature was maintai...

Embodiment 2~6

[0042] Change the mass ratio K1 of hydrochloric acid and ethylene terephthalate (see Table 1 for details), and other process operations are the same as in Example 1, and the hydrolysis resistance of the obtained product is tested, and the results are shown in Table 1.

[0043] Table 1:

[0044]

[0045] It can be concluded from Table 1 that compared with the reference patent CN200610085434.1, the present invention effectively improves the hydrolysis resistance of aluminum nitride powder.

Embodiment 7~12

[0047] Replace ethylene glycol terephthalate with ethyl acetate, change the mass ratio K1 of hydrochloric acid and ethyl acetate simultaneously (see Table 2 for details), other technological operations are the same as embodiment 1, test the hydrolysis resistance of gained product, result See Table 2.

[0048] Table 2:

[0049]

[0050] It can be seen from Table 2 that the present invention can effectively improve the hydrolysis resistance of aluminum nitride powder. Comparing Table 1 and Table 2, it can be seen that when the composition of the mixed solution is hydrochloric acid and ethylene terephthalate, and K1=0.5, the hydrolysis resistance of the aluminum nitride powder obtained is the best.

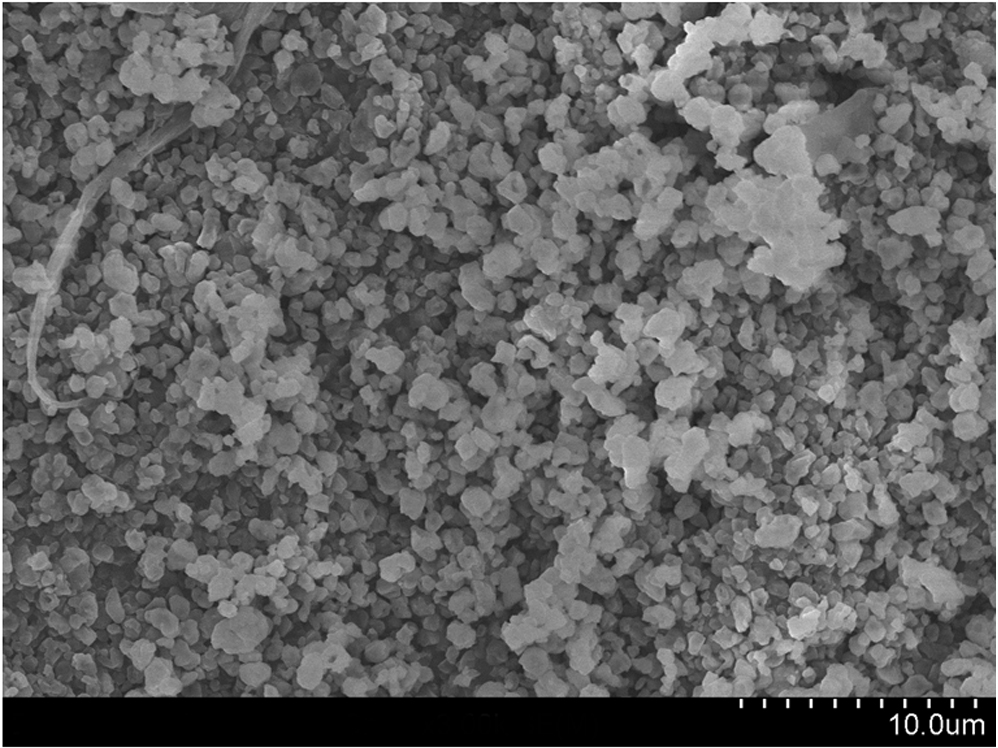

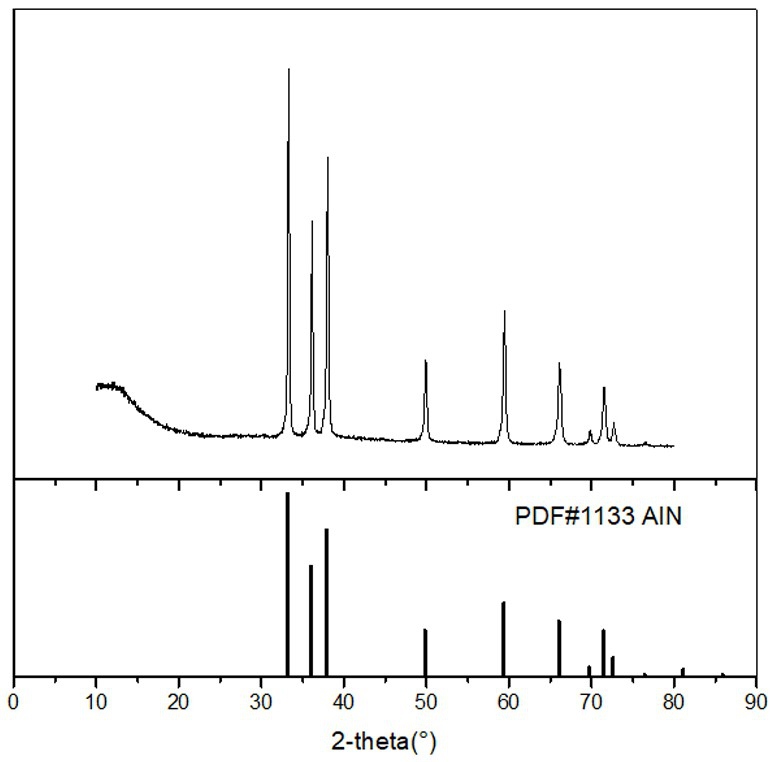

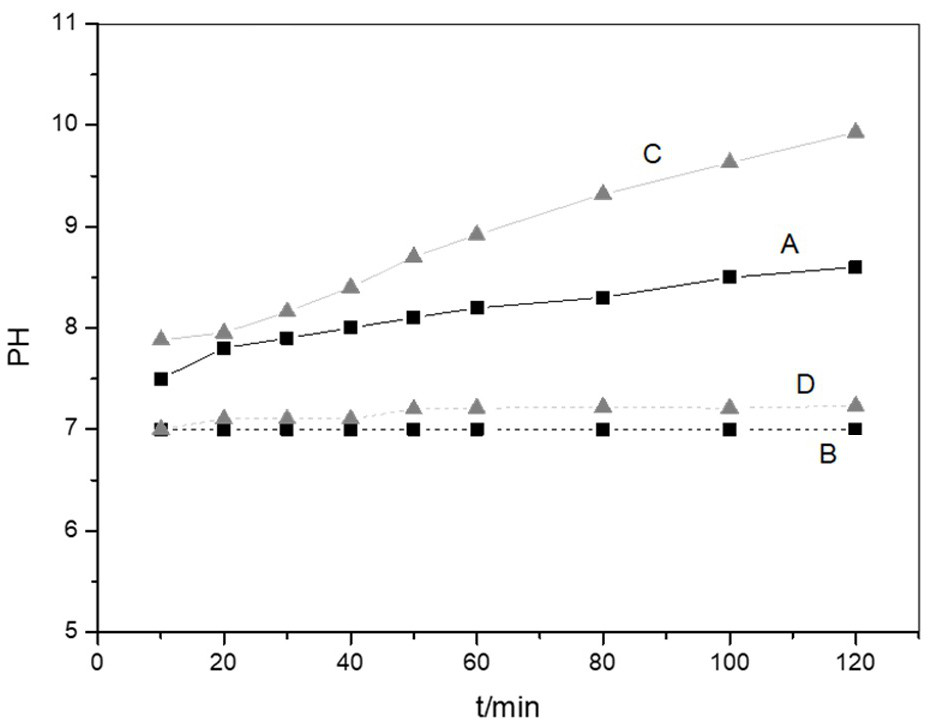

[0051] The aluminum nitride powder prepared in Example 1 and Example 10, the aluminum nitride powder prepared in Reference Example 1, and the control sample (aluminum nitride sample that has not been impregnated with a mixed solution in the present invention) are subjected to an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com