Whole-aryl-cluster luminescent polymer with microporous structure and preparation method of whole-aryl-cluster luminescent polymer

A technology of light-emitting polymer and microporous structure, applied in light-emitting materials, chemical instruments and methods, etc., can solve the problems of deactivation of excited states, poor anti-solvent performance, unsatisfactory quantum yield, etc., and achieve good mechanical properties, Good resistance to solvent corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

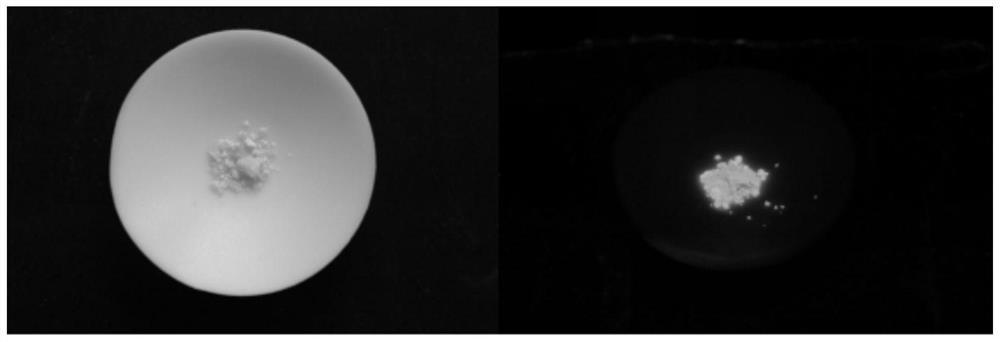

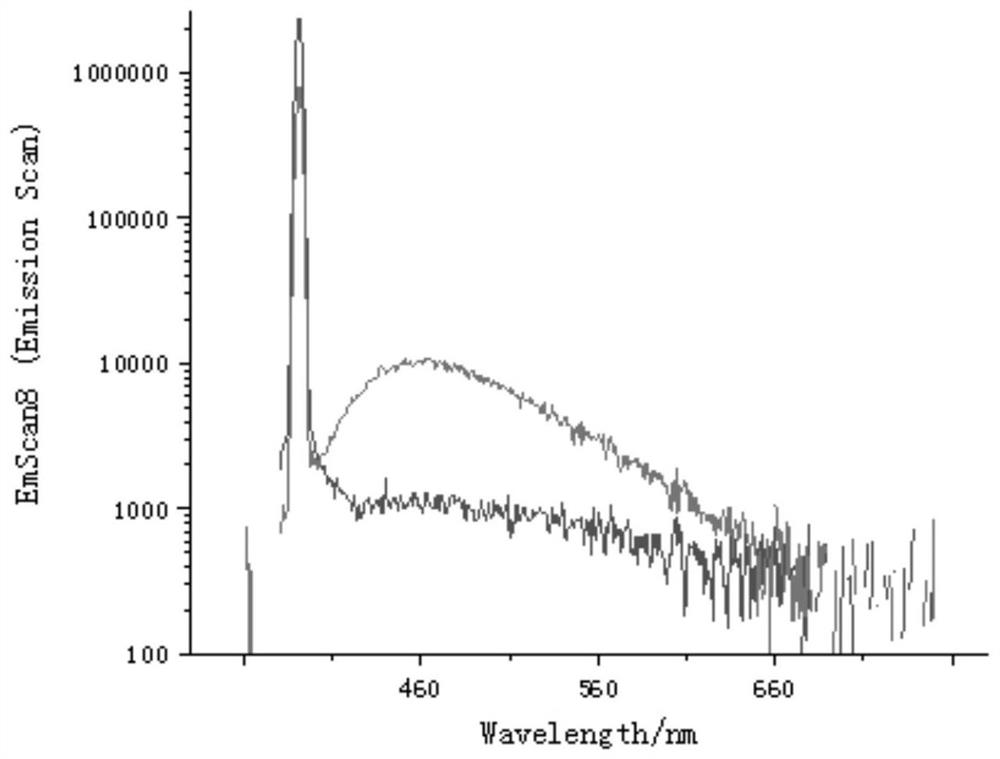

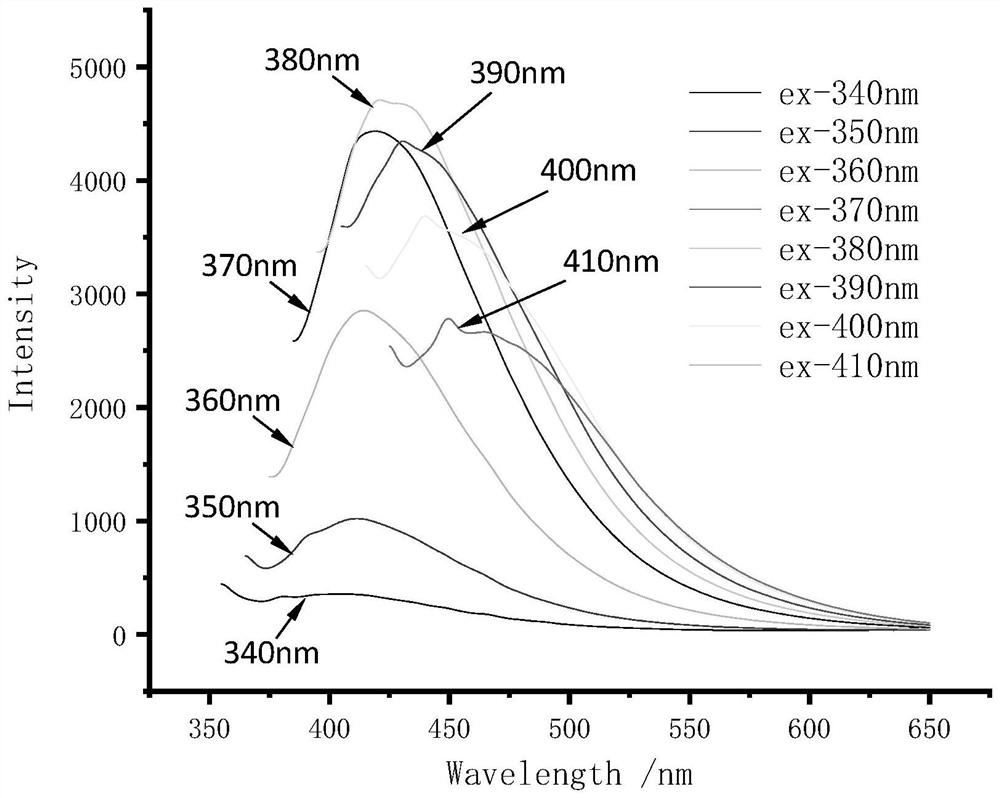

Embodiment 1

[0033] Preparation of all-aryl cluster light-emitting polymers with microporous structure: Vinyl-substituted triphenyltriazine and divinylbenzene were used as reaction monomers, and vinyl-substituted triphenyltriazine (M-TRZ) (670mg, 2mmol) and divinylbenzene (292mg, 2mmol), that is, dissolve in 3ml tetrahydrofuran according to the molar ratio of 50:50, that is, the usage amount of tetrahydrofuran is added according to the total mass ratio of monomers as 0.32g / ml; then add 0.13 mg of azobisisobutyronitrile (AIBN) is used as the initiator, that is, the amount of the initiator AIBN is added according to 0.01% of the total moles of the reaction monomers; the reaction is stirred at a temperature of 50° C. for 48 hours in a nitrogen atmosphere, and the obtained product is first precipitated. Analyzed in methanol, the filtered solid was extracted with dichloromethane for 48 hours, and vacuum-dried to obtain a light yellow solid powder, which was the target polymer (a fully aryl clust...

Embodiment 2

[0036] Preparation of all-aryl cluster light-emitting polymers with microporous structure: Vinyl-substituted triphenyltriazine and divinylbenzene were used as reaction monomers, and vinyl-substituted triphenyltriazine (M-TRZ) And divinylbenzene, be dissolved in tetrahydrofuran according to the molar ratio of 5:95, promptly the consumption of tetrahydrofuran is 2g / ml to add according to monomer total mass ratio; Add azobisisobutyronitrile (AIBN) as initiator again, The amount of the initiator AIBN is added according to 1% of the total moles of the reaction monomers; the reaction is stirred and reacted at 100°C in a nitrogen atmosphere for 96 hours, and the obtained product is first precipitated in methanol, and the filtered solid is then extracted with dichloromethane for 72 hours. The light yellow solid powder obtained by vacuum drying is the target polymer (a whole aryl cluster light-emitting polymer with a microporous structure).

Embodiment 3

[0038] Preparation of all-aryl cluster light-emitting polymers with microporous structure: Vinyl-substituted triphenyltriazine and divinylbenzene were used as reaction monomers, and vinyl-substituted triphenyltriazine (M-TRZ) And divinylbenzene, be dissolved in tetrahydrofuran according to the molar ratio of 75:25, the consumption of tetrahydrofuran is 0.01g / ml to add according to monomer total mass ratio; Add azobisisobutyronitrile (AIBN) as initiator again, The amount of the initiator AIBN is added according to 2% of the total moles of the reaction monomers; the reaction is stirred and reacted at 50° C. in a nitrogen atmosphere for 4 hours, and the obtained product is first precipitated in methanol, and the filtered solid is then extracted with dichloromethane for 6 hours. The light yellow solid powder obtained by vacuum drying is the target polymer (a whole aryl cluster light-emitting polymer with a microporous structure).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com