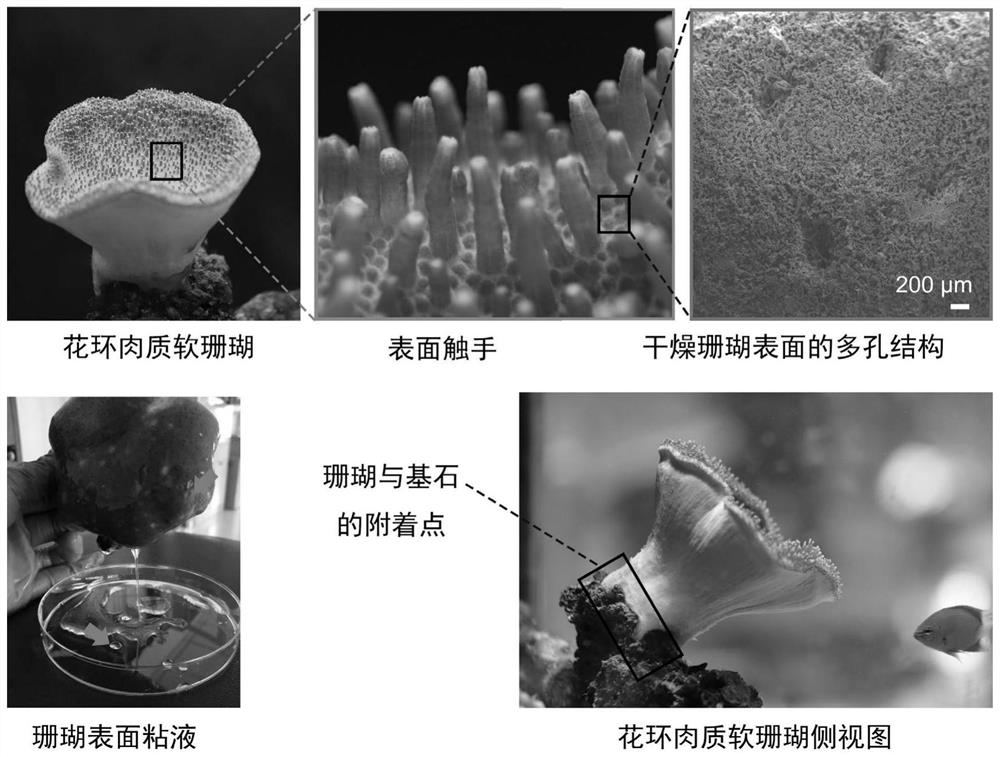

Bionic marine antifouling skin and preparation method thereof

A marine anti-fouling and skin technology, applied in the field of bionic materials, can solve the problems of reduced application value, micro-nano structure damage to anti-fouling performance, failure, etc., and achieve the effect of strong anti-fouling ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

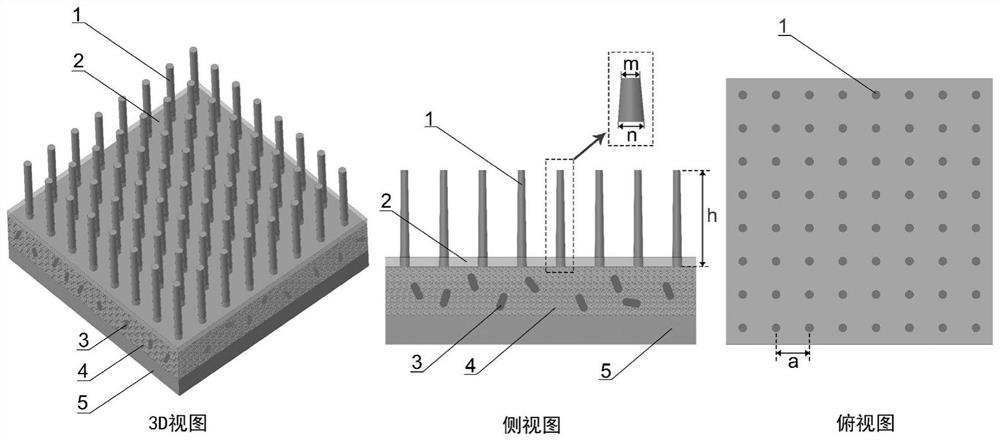

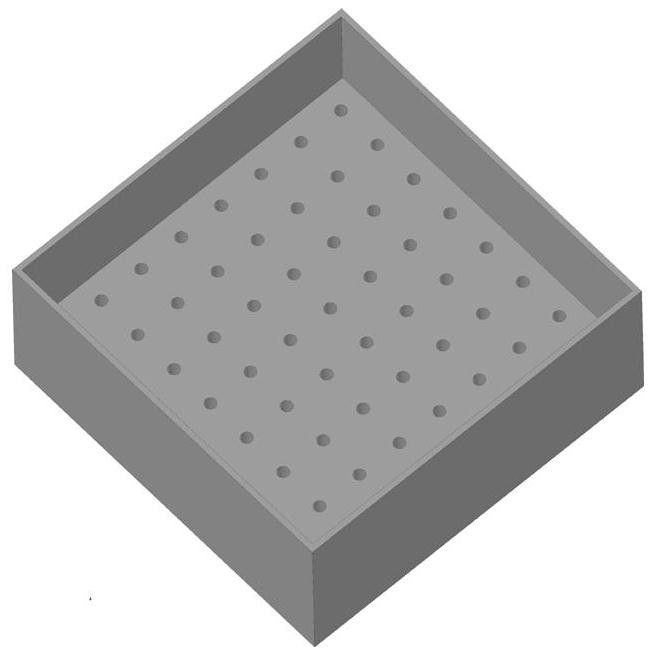

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of biomimetic microcapsules

[0034] The natural polymer calcium alginate is used as the wall material, and the silicone oil or edible oil is used as the core material to prepare biomimetic microcapsules to simulate the secretion of coral mucus. First, silicone oil or edible oil is added to a certain amount of deionized water and a surfactant (such as Span 80), and the mass fraction of the surfactant is 5 to 20 wt%, and then magnetically stirred for a certain period of time (5 minutes to 1 hour) to prepare the oil / Water emulsion, then add calcium alginate solution (mass ratio of calcium alginate to silicone oil / edible oil ranges from 2:1 to 0.5:1) and sonicate for 1 hour, then slowly add 3 to 5% calcium chloride The solution was magnetically stirred, and the formation of capsules was observed under a microscope. After a large number of capsules were formed, the obtained solution was moved into a vacuum drying oven to dry in vacuum for several hours, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com