Degradable colored polyvinyl chloride composition and preparation method thereof

A technology of polyvinyl chloride and composition, applied in the field of degradable colored polyvinyl chloride composition and preparation thereof, can solve the problems of insufficient strength of PVC material, uncontrollable degradation speed, environmental pollution, etc., and achieves rapid degradability, hygiene and safety The effect of degradability, stable coloring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

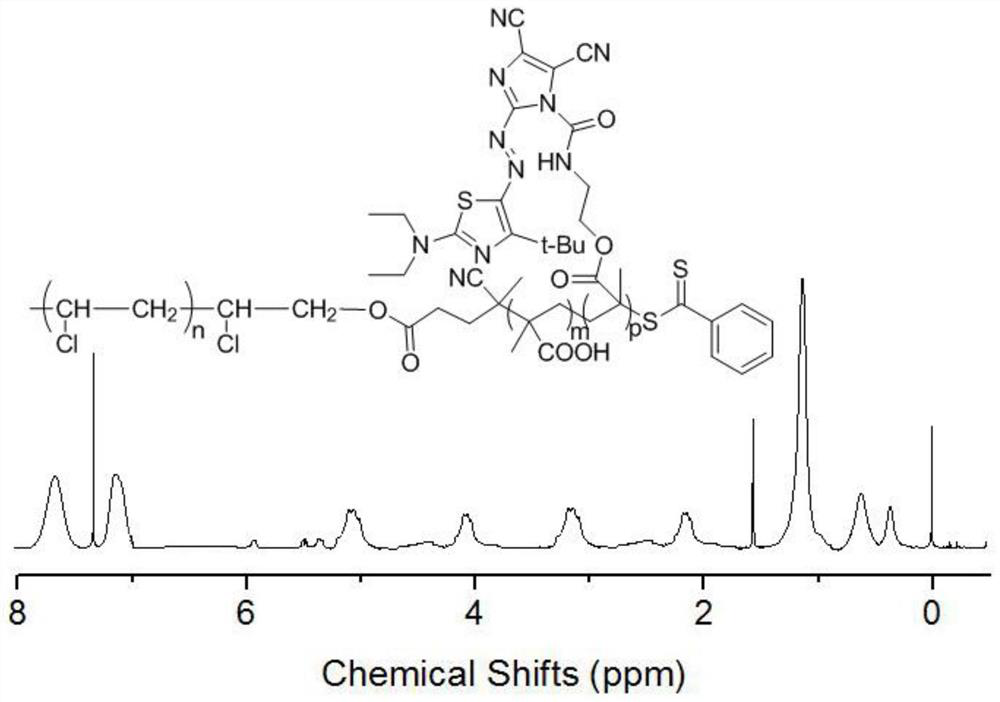

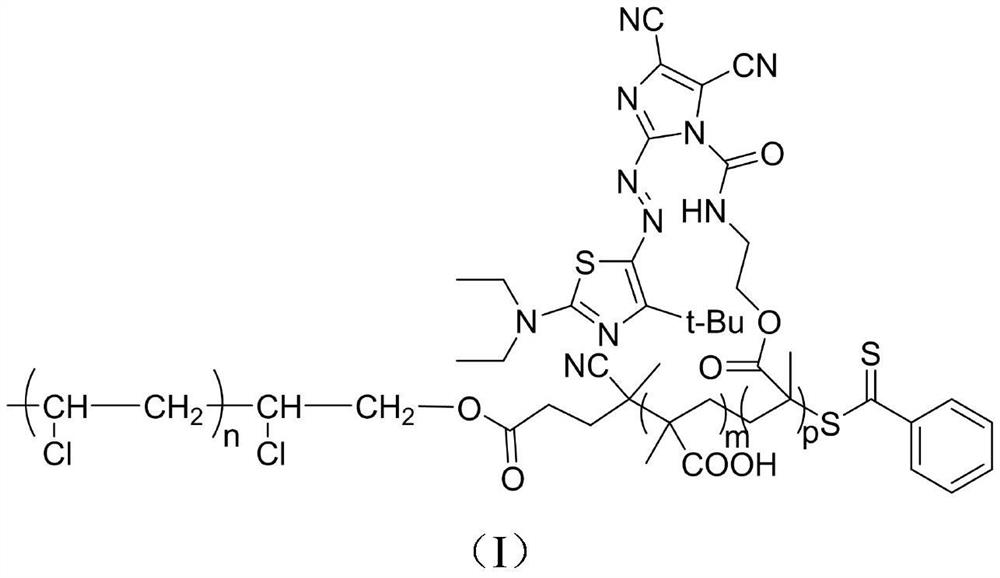

Image

Examples

Embodiment 1

[0031] Preparation of polyvinyl chloride macromolecular chain transfer agent.

[0032] In a 50 mL branched flask, add RAFT reagent 4-cyano-4-(thiobenzoic acid) valeric acid (4.0 mmol) and 20 mL of anhydrous tetrahydrofuran THF, heat up to 70 ° C, dropwise add SOCl 2 (4.0mmol), dropwise completed reaction 2h, decompression distillation removes SOCl 2 and THF to obtain 4-cyano-4-(thiobenzoic acid) valeryl chloride, and add an appropriate amount of toluene to dissolve it.

[0033] N 2 Under protection, add single-terminal hydroxyl polyvinyl chloride PVC-OH (1.0mmol) into a 50ml Schlenk bottle, add 30ml of anhydrous toluene, heat up to 70°C, inject 1ml of pyridine after the PVC-OH is completely dissolved, and stir for 30min , add the above-mentioned 4-cyano-4-(thiobenzoic acid) valeric acid chloride product dropwise, raise the temperature to 75°C and continue the reaction for 2h, after two cycles of continuous dissolution / precipitation in toluene / methanol, dry under vacuum at 45...

Embodiment 2

[0035] Preparation of degradable polyvinyl chloride block copolymers.

[0036] Add methacrylic acid (10.0mmol), polyvinyl chloride macromolecular chain transfer agent (0.1mmol), azobisisobutyronitrile (0.01mmol) into a 50ml Schlenk bottle, N 2 Under protection, add 20mL N,N-dimethylformamide, react at 60°C for 8h, put the product into liquid nitrogen to quench the reaction to stop the reaction, use methanol / water as the precipitant, repeat the precipitation 3 times, vacuum 45 Dry at ℃ to constant weight to obtain a degradable polyvinyl chloride block copolymer with a yield of 76.3%.

Embodiment 3

[0038] Preparation of colored polyvinyl chloride block copolymers.

[0039] Add colorant (10.0mmol), polyvinyl chloride macromolecular chain transfer agent (0.1mmol), azobisisobutyronitrile (0.01mmol) into a 50ml Schlenk bottle, N 2 Under protection, add 20mL N,N-dimethylformamide, react at 60°C for 8h, put the product into liquid nitrogen to quench the reaction to stop the reaction, use methanol / water as the precipitant, repeat the precipitation 3 times, vacuum 45 Dry at ℃ to constant weight to obtain a degradable polyvinyl chloride block copolymer with a yield of 76.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com