Purification assembly and filtering device applying purification assembly

A technology of purification components and filter devices, which is applied in the field of air purification, can solve problems such as easy generation of ozone, high cost, and weakened purification efficiency, and achieve the effects of improved filtration efficiency, high porosity, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

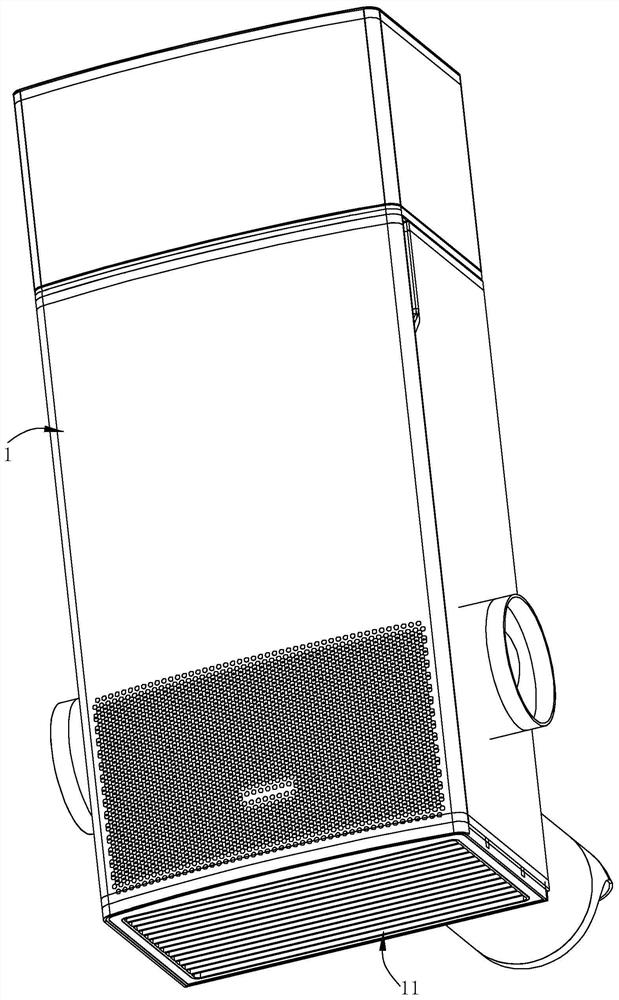

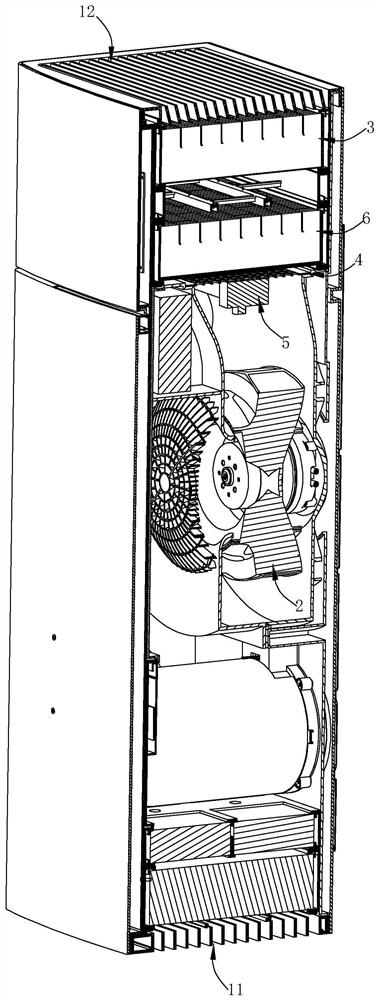

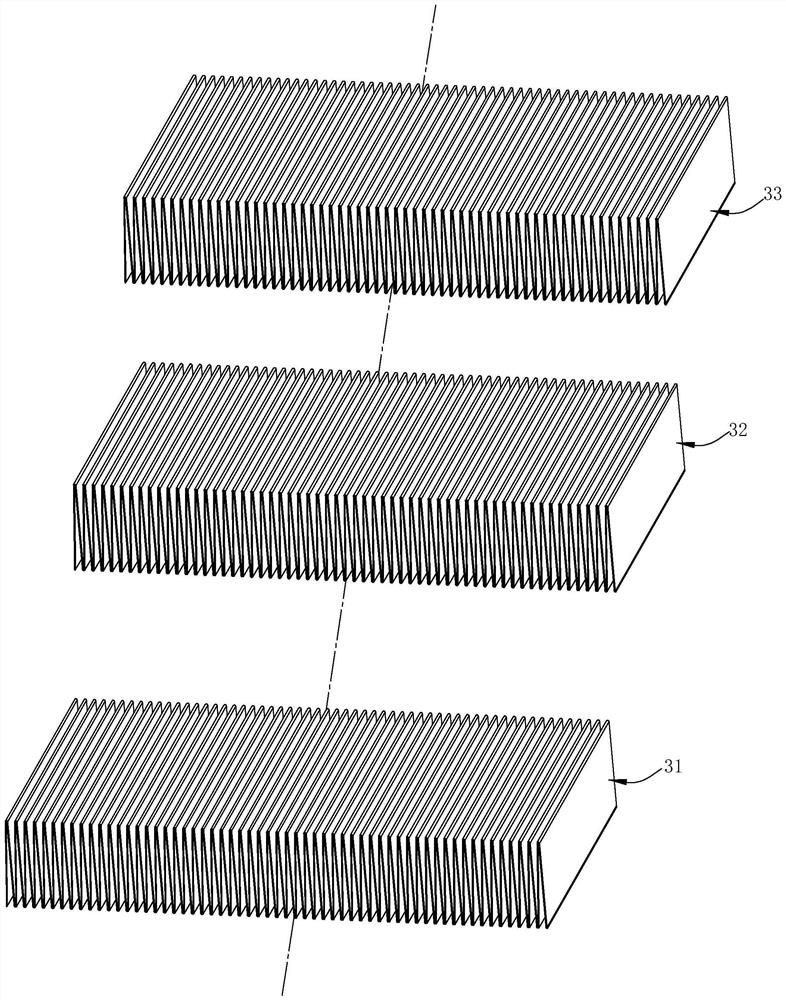

[0036] Such as Figure 1-9 As shown, the filter device of this preferred embodiment includes a housing 1 , a fan 2 , a purification component 3 , a grid 4 , a heating element 5 and a fourth filter 6 .

[0037] The housing 1 is provided with an air inlet 11 and an air outlet 12, and a filter channel is formed inside the housing 1. The filter channel is surrounded by a plurality of frames, and the filter channel is provided with a filter channel to introduce the air flow from the air inlet 11 to the air outlet. 12 The blower fan 2 blown out is also provided with a heating element 5, a grid net 4, a fourth filter screen 6 and a purification assembly 3 arranged in sequence in the downstream of the fan 2 along the flow direction of the airflow, the fan 2, the heating Part 5, grid net 4, fourth filter net 6 and purification component 3 are all fixedly arranged in the frame body.

[0038] Such as figure 2 The grid net 4 shown is arranged horizontally, and the airflow passes throug...

Embodiment 2

[0050] The difference between embodiment 2 and embodiment 1 is:

[0051] The preparation method of the third filter screen 33 of the present embodiment comprises the following steps:

[0052] (1) Add 1.3g of nano-anion powder into 85g of organic solvent N, N-dimethylformamide DMF, ultrasonically disperse for 40 minutes, after the dispersion is completed, use a particle size disperser to detect that the particle size of the nano-anion powder is distributed between 20 and 50nm , then add 13.7g polyacrylonitrile PAN (Hubei Dechao Chemical Co., Ltd.), stir evenly at 40°C, then let it stand for cooling for 12h, and prepare a spinning solution with a concentration of 15wt%. The viscosity of the spinning solution is 1100mPa·s;

[0053] (2) Use non-woven fabric as the collecting base cloth, cover the collecting base cloth on the collector, put the spinning solution into the needle tube, and carry out electrostatic spinning on the spinning solution, adjust the spinning parameters to 16...

Embodiment 3

[0056] The difference between embodiment 3 and embodiment 1 is:

[0057] The preparation method of the third filter screen 33 of the present embodiment comprises the following steps:

[0058] (1) Add 1.9g of nano-anion powder into 85g of organic solvent N,N-dimethylacetamide 80gDMAC, ultrasonically disperse for 40min, after the dispersion is completed, detect with a particle size disperser, the particle size of the nano-anion powder is distributed between 20-50nm , then add 18.1g polyvinylidene fluoride PVDF (Solwei Specialty Polymer Co., Ltd.), stir evenly at 40°C, then let it stand for cooling for 12h, and be prepared with a spinning solution of 20wt% concentration, and the viscosity of the spinning solution is 1950mPa. s;

[0059] (2) Use non-woven fabric as the collection base cloth, cover the collection base cloth on the collector, put the spinning solution into the needle tube, and carry out electrostatic spinning on the spinning solution, adjust the spinning parameters...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com