All-solid-state vector Z mechanism composite photocatalyst CaTiO3/Cu/TiO2 as well as preparation method and application thereof

A composite photo-catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of cost limitation and application, and achieve the effects of reducing recombination efficiency, promoting separation, and increasing specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1)CaTiO 3 Preparation of photocatalyst

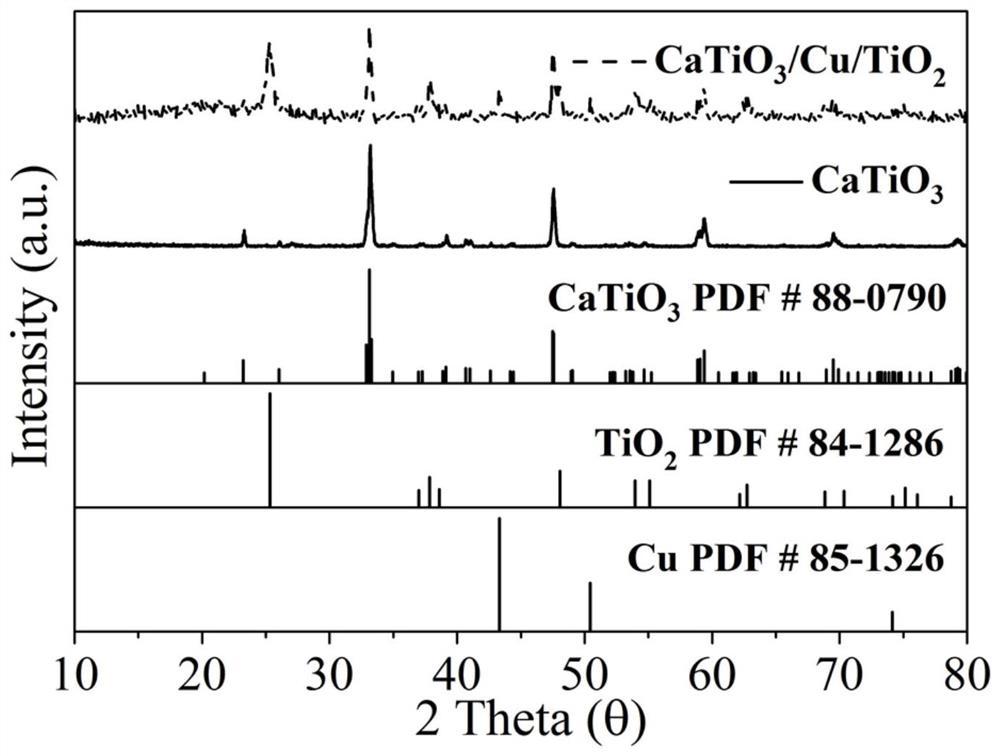

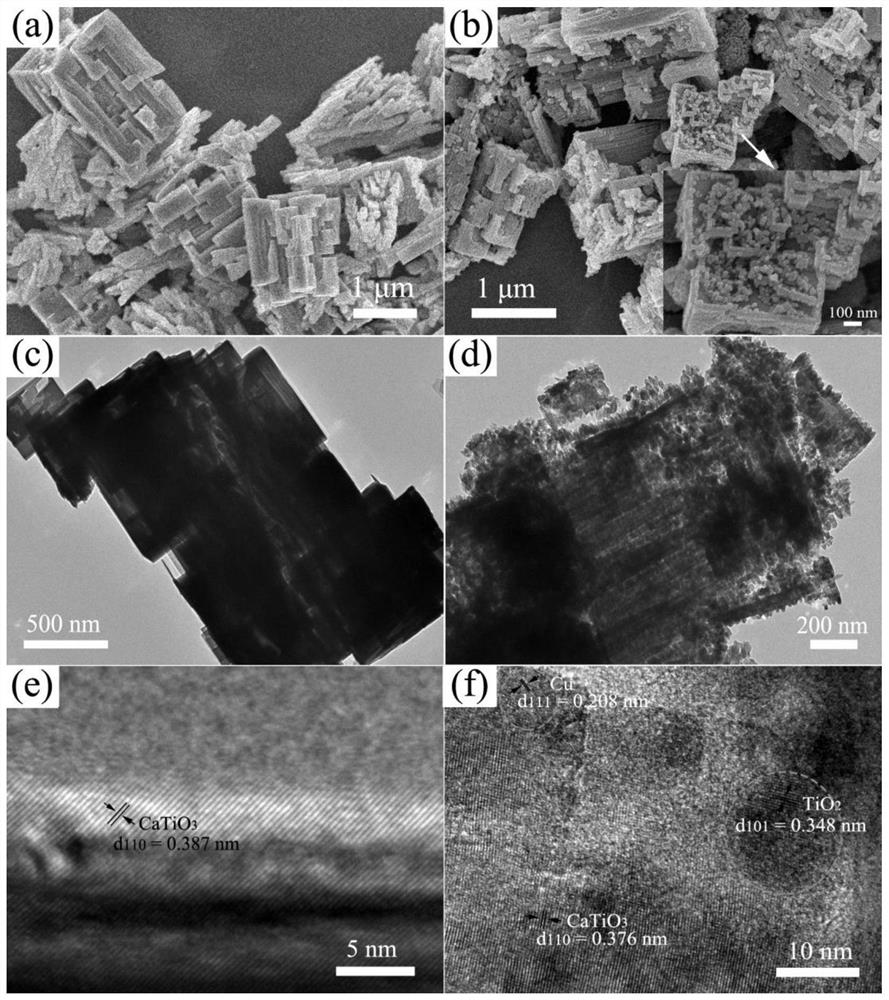

[0028] First, 1.18g Ca(NO 3 ) 2 4H 2 O was dissolved in 20mL of deionized water, stirred magnetically for 10min (the rotating speed of magnetic stirring was 300rpm), and then added 1.7mL [Ti(C 4 h 9 O) 4 ] and 0.4g NaOH. After another 1 h of magnetic stirring (the rotational speed of magnetic stirring was 300 rpm), the white suspension was transferred to a 30 mL polytetrafluoroethylene-lined stainless steel autoclave, and hydrothermally treated at 180 °C for 24 h. After the reaction, the reactor was naturally cooled to room temperature. Finally, the white precipitate was washed to neutral with dilute acetic acid solution, then centrifuged and washed several times with deionized water and absolute ethanol (centrifugal speed was 8000rpm), and dried at 60°C for 12h to obtain CaTiO 3 , the product mass is 0.4g.

[0029] 2)CaTiO 3 / Cu / TiO 2 Preparation of composite photocatalytic materials

[0030] 20mg Cu(CH 3 COO) 2 ·H...

Embodiment 2

[0039] As in the steps of Example 1, the difference is that Example 2 prepares CaTiO 3 / Cu / TiO 2 When composite photocatalyst, Cu(CH 3 COO) 2 ·H 2 The mass of O was changed from 20mg to 10mg, resulting in CaTiO 3 / Cu / TiO 2 Composite photocatalyst, the product quality is 30mg. The hydrogen production rate of the catalyst is 17.038mmol g -1 h -1 .

Embodiment 3

[0041] As in the steps of Example 1, the difference is that Example 3 prepares CaTiO 3 / Cu / TiO 2 When composite photocatalyst, Cu(CH 3 COO) 2 ·H 2 The mass of O was changed from 20 mg to 30 mg to obtain CaTiO 3 / Cu / TiO 2 Composite photocatalyst, the product quality is 30mg. The hydrogen production rate of the catalyst is 17.926mmol g -1 h -1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com