A kind of small molecular polymer for reducing the viscosity of high-grade concrete and its preparation method

A concrete and small molecule technology, applied in the field of concrete, can solve the problems of diversification of sand and gravel sources, high-quality raw material supply shortage, high impurity content, etc., and achieve the effect of uniform polymer molecular weight distribution, simple synthesis process, and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

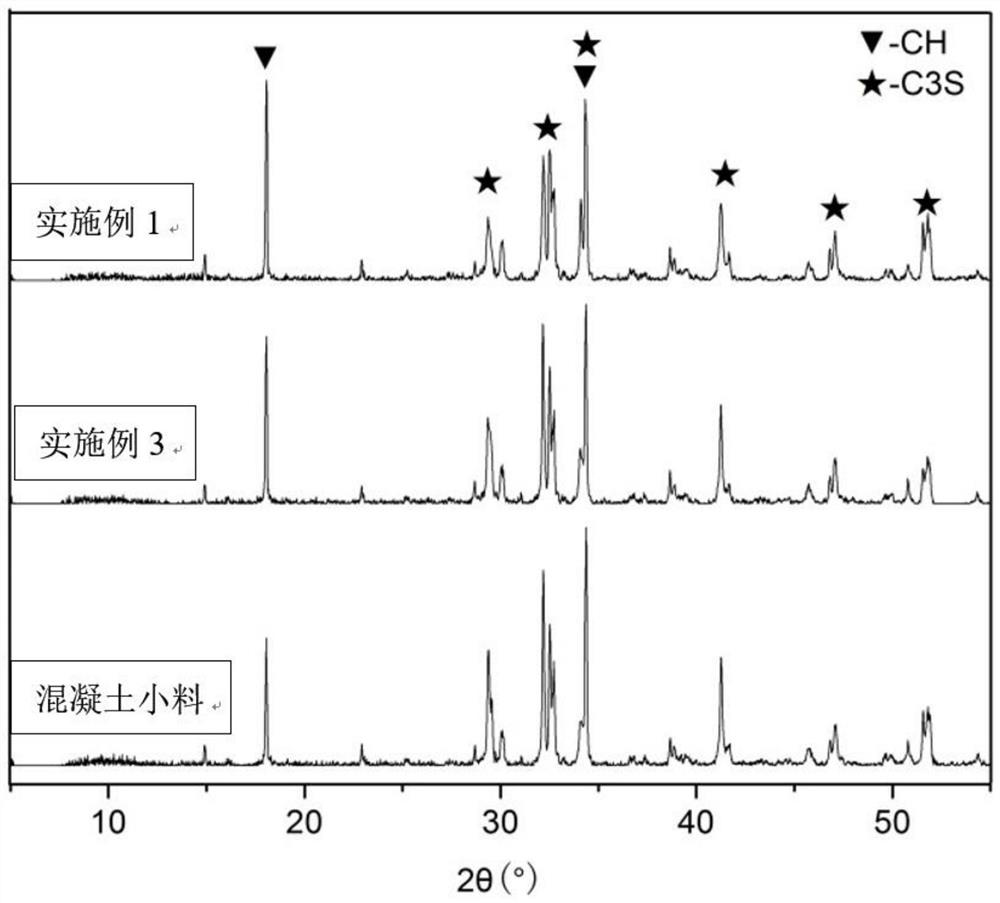

Image

Examples

Embodiment 1

[0037] The total mass fraction of the raw materials for preparing the small molecule polymer is 1000 parts, each mass fraction in this embodiment is 1 g, and the mass fractions of each raw material component are as follows:

[0038] 4-Vinylphenol: 25 parts

[0039] Trans-2.3-butylene oxide: 300 parts

[0040] Acetomethanesulfonic acid: 13 parts

[0041] Lithium aluminum tetrahydrogen: 0.10 parts

[0042] Potassium hydroxide: 0.11 parts

[0043] Acrylic: 50 parts

[0044] Ammonium persulfate: 2.2 parts

[0045] Ascorbic acid: 4.5 servings

[0046] 1:2 mercaptopropionic acid and thioglycolic acid: 1.2 parts

[0047] Sodium hydroxide: 5.4 parts

[0048] The rest is deionized water.

[0049] The preparation method is as follows:

[0050] (1) Preparation of unsaturated intermediates

[0051] (1.1) add 25 parts of 4-vinyl phenol in the autoclave, add 0.10 part of lithium aluminum tetrahydrogen, then under stirring, carry out nitrogen replacement 4 times, turn on the heatin...

Embodiment 2-6

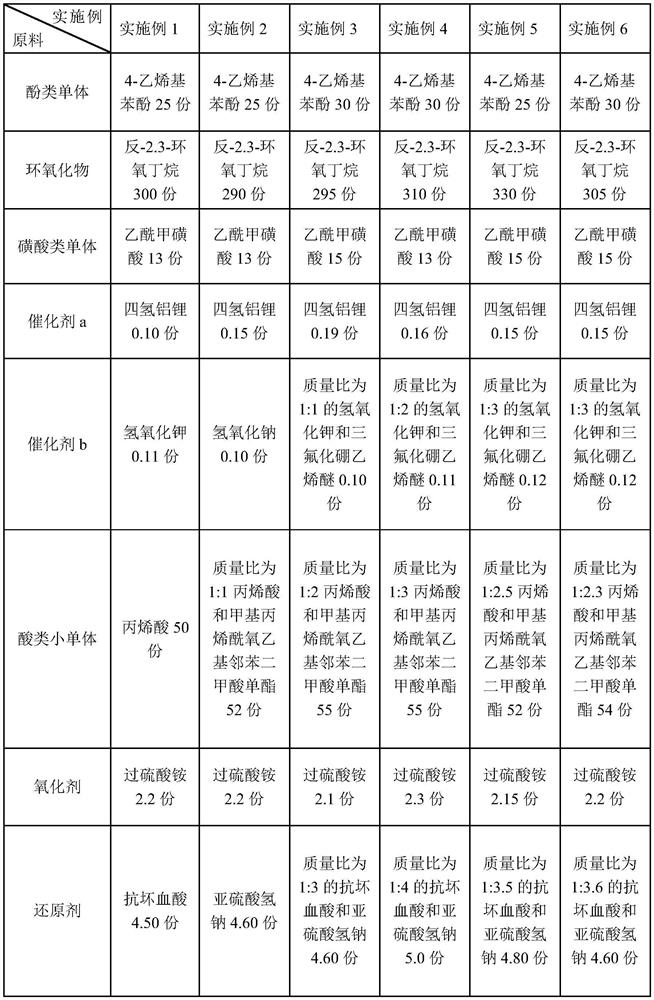

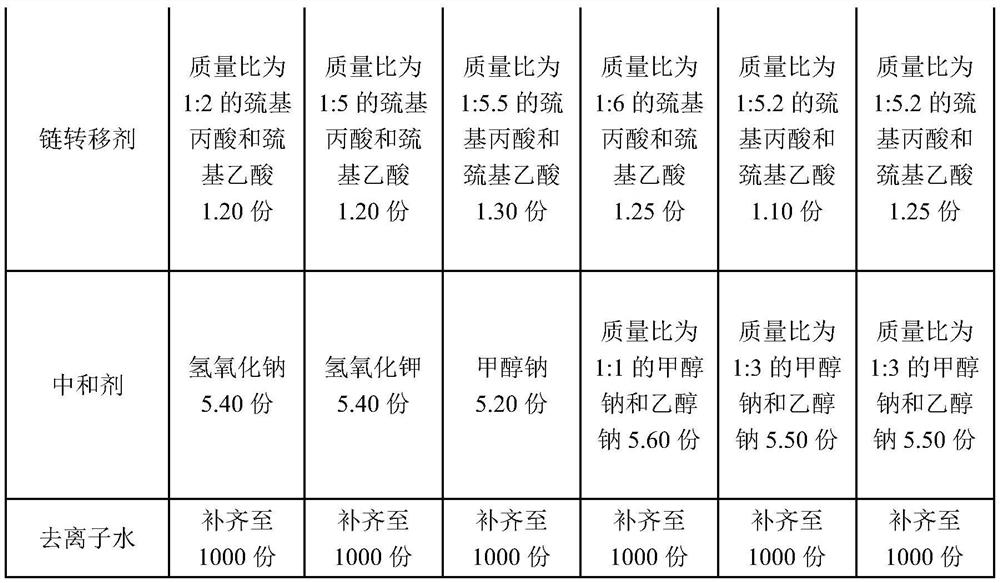

[0060] The specific parameters (the steps are the same) in the specific raw materials and the preparation method are different from those in Example 1, as shown in Table 1 and Table 2 below (Table 1 is the raw material, and Table 2 is the parameter in the preparation method), in Table 2 Those not listed are the same as in Example 1:

[0061] Table 1

[0062]

[0063]

[0064] Table 2

[0065]

[0066]

[0067] The product of the present invention and Qingdao Dingchang ZN-2017-A concrete batch are made into C50 concrete samples, and the following table is obtained after testing. (Dosage 0.3wt%) (Viscosity is tested by R / S-SST2000 Soft Solid Rheometer manufactured by Brookfield Company in the United States. Air content is tested according to the standard of GB / T50080-2002.)

[0068] table 3

[0069]

[0070] Through the comparative analysis of the test data in the above table, it can be clearly seen that the polymer prepared by the present invention has good vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com