Preparation method of tungsten ditelluride nanobelt

A tungsten ditelluride and nanobelt technology, applied in binary selenium/tellurium compounds, nanotechnology, metal selenide/telluride, etc., can solve the problem of inability to achieve large-area production, consuming a lot of time and energy, and reducing device performance. and other problems, to achieve the effect of reducing temperature, realizing recycling and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] SiO to be purchased 2 / Si (300nm) substrate was sheared to obtain a substrate with a size of 1cm×1cm, which was cleaned with acetone solution, isopropanol solution, ethanol solution and deionized water in sequence, and then dried under nitrogen atmosphere. Place the treated substrate and tungsten foil as follows: first place the polished side of the silicon wafer on the graphite sheet, and then place the oxidized tungsten foil (conventional oxidation treatment: place the tungsten foil on a 5 cm outer diameter, In a clean quartz glass tube with a length of 1m, oxidize at 700°C for 60min) to cover the silicon wafer, place a gasket between the substrate and the tungsten foil, then place the graphite sheet in the center of the tube furnace, and finally put the tellurium powder The alumina porcelain boat is placed upstream of the tube furnace. The mass of the tellurium powder is 600mg, the size of the tungsten foil is 1cm x 1cm, and the distance between the tellurium powder...

Embodiment 2 to 4

[0040] The silicon dioxide substrate in Example 1 was replaced by a sapphire substrate, a glass substrate, and a mica substrate respectively, and other preparation conditions remained unchanged, and tungsten ditelluride nanobelts with better quality could also be prepared.

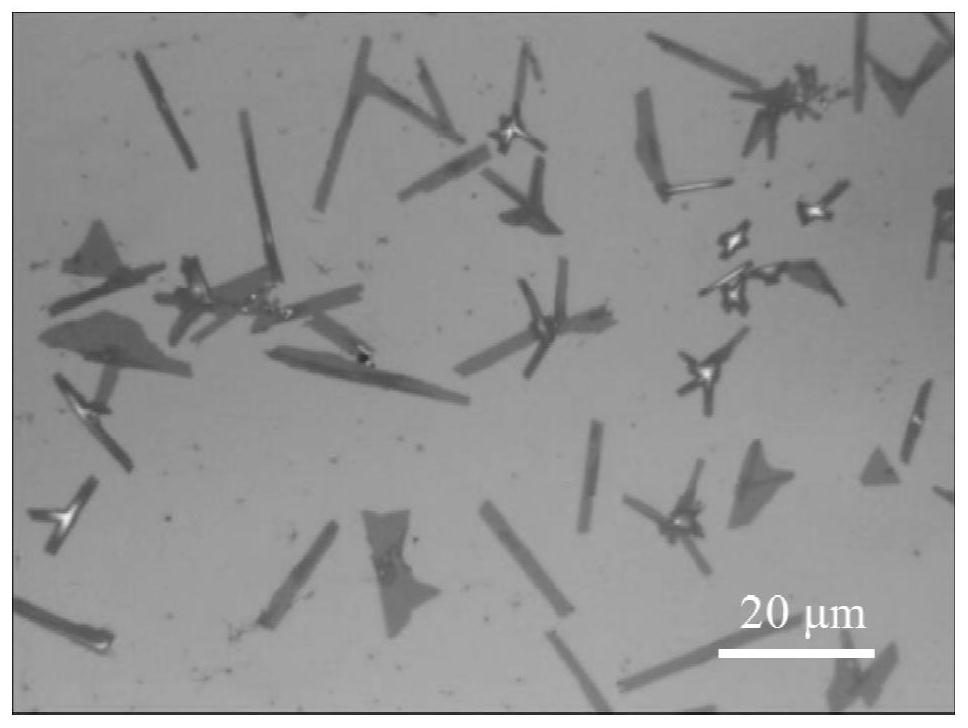

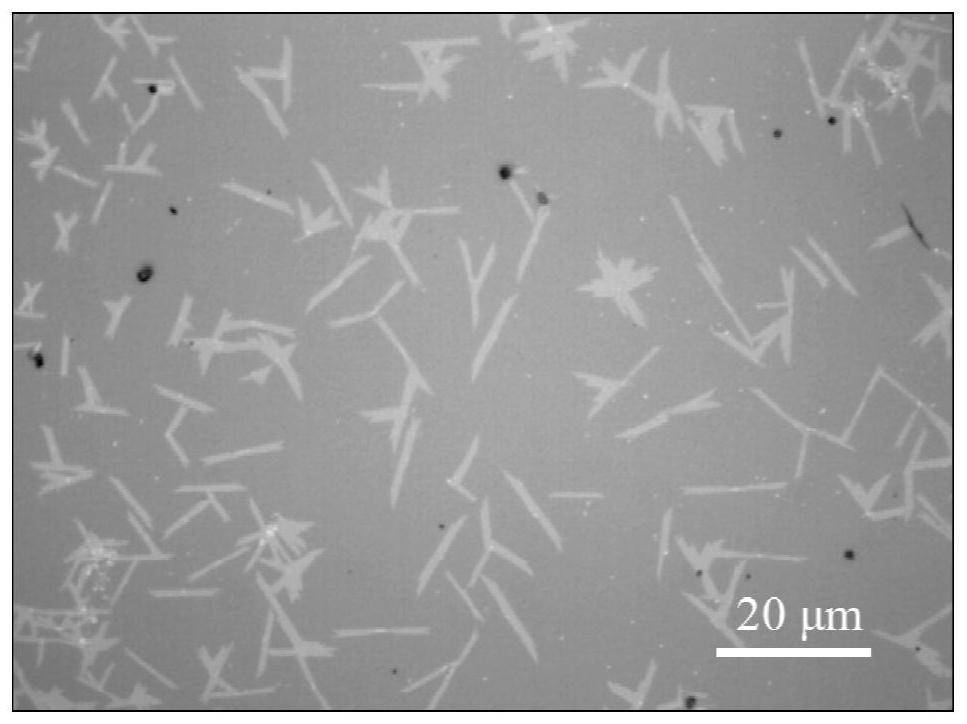

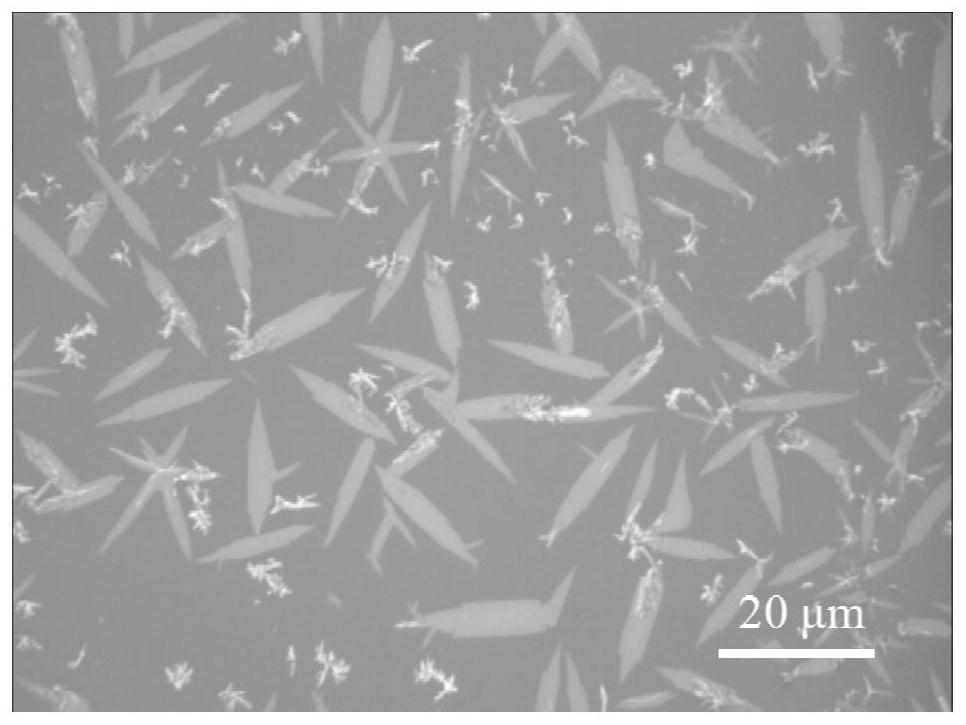

[0041]The obtained tungsten ditelluride nanosheet sample is subjected to optical microscope, Raman, atomic force characterization, surface potential, scanning electron microscope characterization transmission electron microscope and XPS characterization, the results are as follows figure 1 , 2, 3, 4, 5, 6, 7, 8, 9, 10, 11, 12 and 13. It can be seen from the optical microscope characterization data that there are two-dimensional nanosheets of different layers and sizes on the silica, sapphire, and glass substrates. Taking the product obtained in Example 1 as an example, it can be seen from the Raman characterization data that the sample obtained in Example 1 is at 163 cm -1 and 212cm -1 for WTe 2 Two typ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com