Method for regulating and controlling porous carbon prepared by high internal phase emulsion template method through aldose

A technology of high internal phase emulsion and template method, which is applied in the preparation/purification of carbon, can solve the problems of unsatisfactory health, environmental protection and sustainable development, and achieve the effect of controllable pore size and distribution, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

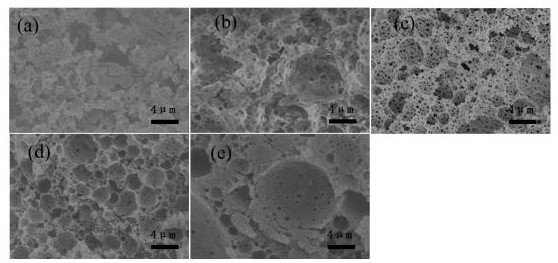

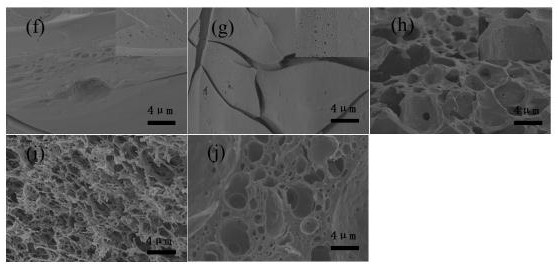

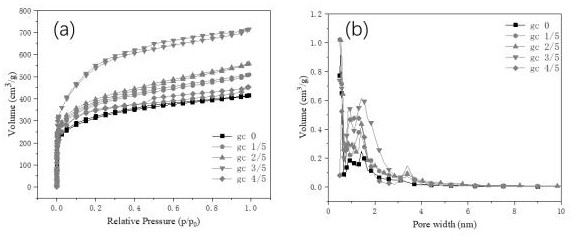

Embodiment 1

[0034] First, dissolve melamine, glucose, formaldehyde solution, hydrochloric acid, anhydrous sodium carbonate and Tween 20 in deionized water to obtain an aqueous phase, the mass fraction of Tween 20 in the aqueous phase is 10%, and anhydrous sodium carbonate in the aqueous phase The mass fraction of glucose and formaldehyde is 0.03%, the mass ratio of glucose and formaldehyde is 0:5, the molar ratio of melamine and formaldehyde is 1:10.8, and the mass fraction of formaldehyde solution is 37%; Slowly drop toluene into water under the condition of mechanical stirring phase (dropping within 2 hours), continue to stir for 2 hours after the addition is completed to obtain an oil-in-water type high internal phase emulsion with an internal phase volume fraction of 75%; after sealing, carry out polymerization reaction at 80 ° C, and obtain a solid block after 24 hours of reaction The crude product was Soxhlet-extracted in absolute ethanol for 12 hours, the inner phase was removed, an...

Embodiment 2

[0035] Example 2: The specific experimental steps are the same as in Example 1, and the mass ratio of glucose to formaldehyde in the aqueous phase of the prepared high internal phase emulsion is 1:5. The number is gc1 / 5.

Embodiment 3

[0036] Example 3: The specific experimental steps are the same as in Example 1, and the mass ratio of glucose to formaldehyde in the aqueous phase of the prepared high internal phase emulsion is 2:5. The number is gc2 / 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com