Deep denitrification system and method based on heterotrophic-autotrophic combined treatment

A deep denitrification and combined treatment technology, applied in the field of deep denitrification systems, can solve the problems of poor shock load resistance, unstable water output, and high operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Bacteria cultivation and acclimation stage: Heterotrophic deep denitrification unit and autotrophic deep denitrification unit are used for microbial culture, the microorganisms used are taken from strains, and nitrogen-containing wastewater is used to start the culture. The heterotrophic deep denitrification unit cultivates heterotrophic bacteria, which are used to consume the remaining degradable carbon-containing organic matter in the tail water; the autotrophic deep denitrification unit cultivates sulfur autotrophic bacteria, which are used for further denitrification.

[0038] After the sludge has been cultivated for about two weeks, sulfur is added to the autotrophic deep denitrification unit for enrichment culture, and denitrification sludge with autotrophic characteristics is domesticated and cultivated. During the cultivation period, the nutrient solution was added every two days and the supernatant was replaced once. The main component of the nutrient solution w...

Embodiment 2

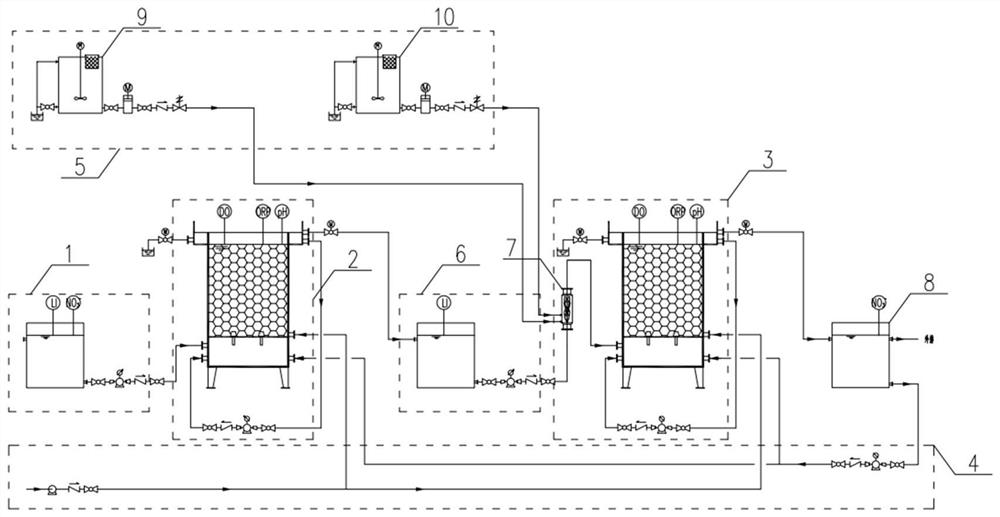

[0046] The water treatment process steps of this system are: the sewage after the secondary biochemical treatment first enters the water inlet tank 1, when the intelligent water inlet analysis unit judges that the liquid level of the water collection tank is high, start the lifting pump to drive the sewage into the heterotrophic depth The denitrification unit stops until the liquid level of the water inlet tank 1 is lower again.

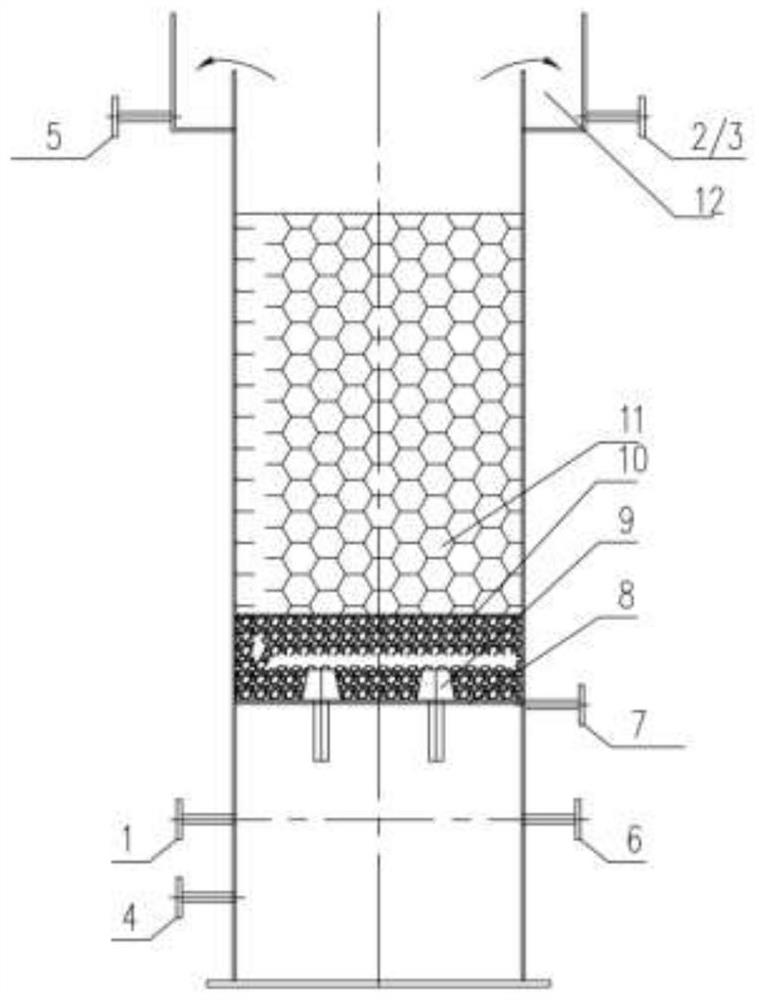

[0047] The sewage entering the heterotrophic deep denitrification unit and the effluent from the autotrophic deep denitrification unit after sulfur autotrophic denitrification enter the bottom of the heterotrophic deep denitrification unit according to the reflux ratio, first pass through the water distribution filter head at the bottom, and then evenly mix with the The biofilm on the filler is in contact, and the heterotrophic bacteria use the organic matter in the influent as a carbon source to convert part of the NO in the influent 3 - -N convert...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com