A kind of water-reactive one-component environment-friendly polyurethane grouting resin and production method

A reactive, one-component technology, applied in the field of grouting resin, can solve the problems of increasing the complexity of product production, easy to block equipment, complicated equipment cleaning, etc., to achieve flexible and simple construction, long-term blocking effect, resistance to High compressive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

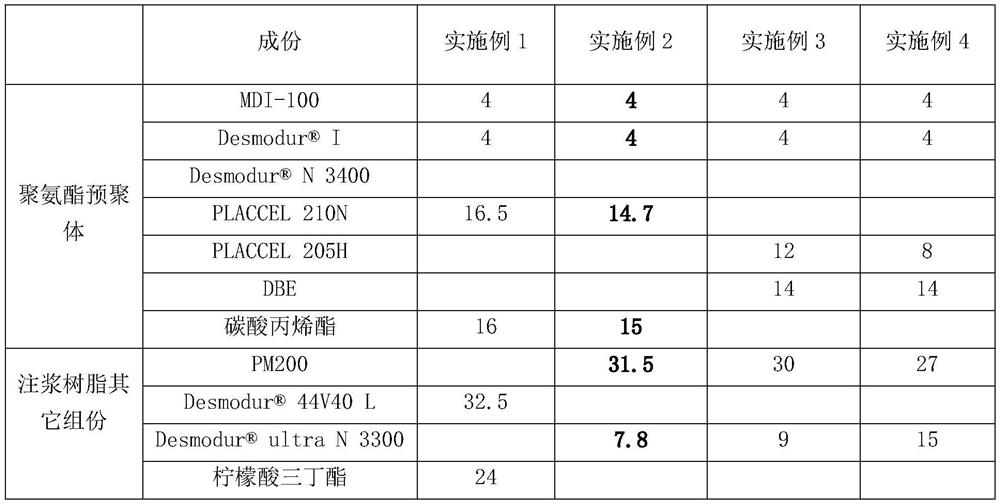

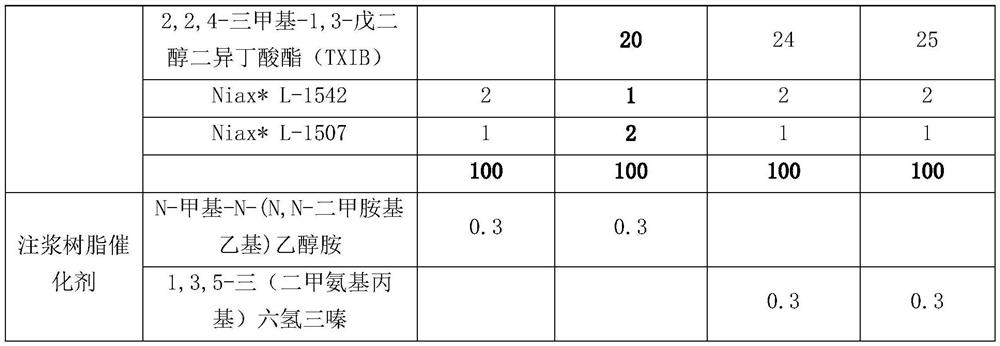

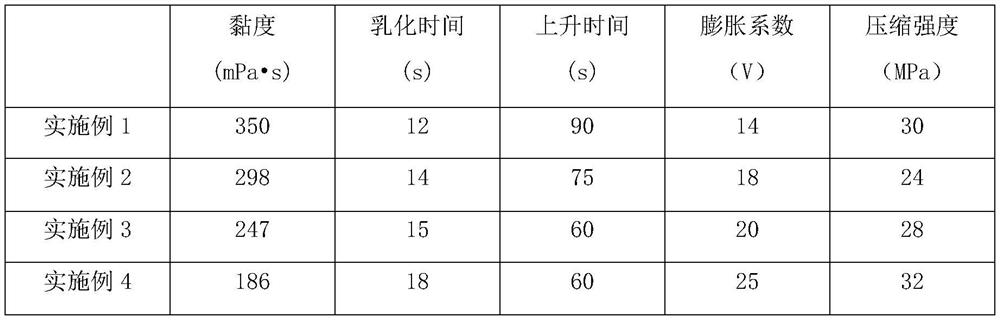

Examples

Embodiment 1

[0021] The water-reactive one-component environment-friendly polyurethane grouting resin according to the present invention adopts the technical scheme that a non-TDI-based polymer is used as the main resin component, and an environment-friendly high-boiling-point diluent, non-PAEs enhancer is assisted. It is formulated with plasticizer, silicone foam stabilizer, balanced foaming gel catalyst and flame retardant.

[0022] The non-TDI-based polymer is a -NCO-terminated polyurethane prepolymer formed by the polymerization of diphenylmethane diisocyanate (MDI), isophorone diisocyanate (IPDI) monomer and oligomer polyol, Described diphenylmethane diisocyanate (MDI) selects the one produced by Yantai Wanhua for use Described isophorone diisocyanate (IPDI) selects Covestro to produce 1, the oligomer polyol is polycaprolactone diol (PCL), and the polycaprolactone diol (PCL) is selected in PLACCEL 210N and PLACCEL 205H produced by Japan DAICEL with a molecular weight in the range o...

Embodiment 2

[0038] A method for producing a water-reactive one-component environment-friendly polyurethane grouting resin, characterized in that the method comprises the following steps:

[0039] Step 1: Raw material treatment: PLACCEL 210N is dehydrated for 2 hours in a vacuum drying oven at 90°C and a vacuum degree of 0.1MPa before use; mixed dibasic acid ester (DBE), propylene carbonate, tributyl citrate, 2 ,2,4-trimethyl-1,3-pentanediol diisobutyrate (TXIB) was soaked with molecular sieve; diphenylmethane diisocyanate (MDI) and isophorone diisocyanate (IPDI) were used directly;

[0040] Step 2: Preparation of polyurethane prepolymer: PLACCEL 210N was put into a reaction kettle with a thermometer, stirring device, condensation reflux tube, constant pressure dropping funnel, and nitrogen ventilation device according to the formula ratio, and the temperature of the reaction kettle was raised to 80 ° C; at this temperature, isophorone diisocyanate (IPDI) was added dropwise to the reactor,...

Embodiment 3

[0047] A method for producing a water-reactive one-component environment-friendly polyurethane grouting resin, characterized in that the method comprises the following steps:

[0048] Step 1: Raw material treatment: PLACCEL 205H was dehydrated for 2 hours in a vacuum drying oven at 90°C and a vacuum degree of 0.1MPa before use; mixed dibasic acid ester (DBE), propylene carbonate, tributyl citrate, 2 ,2,4-trimethyl-1,3-pentanediol diisobutyrate (TXIB) was soaked with molecular sieve; diphenylmethane diisocyanate (MDI) and isophorone diisocyanate (IPDI) were used directly;

[0049] Step 2: Preparation of polyurethane prepolymer: PLACCEL 205H was put into a reaction kettle with a thermometer, stirring device, condensation reflux tube, constant pressure dropping funnel, and nitrogen ventilation device according to the formula ratio, and the temperature of the reaction kettle was raised to 80 ° C; at this temperature, isophorone diisocyanate (IPDI) was added dropwise to the reactor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com