Antibacterial and puncture-resistant biodegradable packaging bag and preparation method thereof

A biodegradable packaging bag technology, applied in the field of biodegradable packaging materials, can solve the problem of antibacterial durability and puncture resistance of packaging bags, low weighing capacity of degradable plastic bags, and inability to meet the load-bearing requirements of various things, etc. problems, to achieve the effect of improving mechanical properties and puncture resistance, improving interfacial compatibility, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

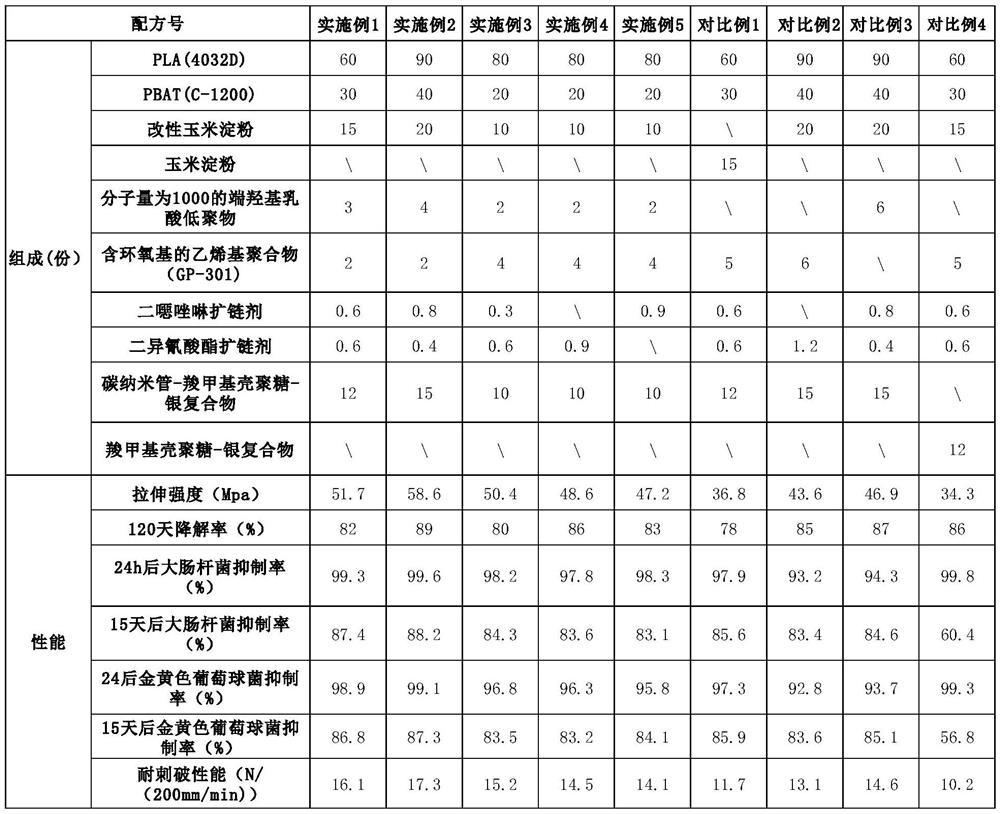

Examples

preparation example Construction

[0051] The preparation process of carboxymethyl chitosan-silver complex is as follows: add carboxymethyl chitosan to deionized water, ultrasonically disperse evenly, and then add AgNO with a mass concentration of 8g / L 3 Solution, stirred at constant temperature to make it fully fused and reacted, slowly drip sodium hydroxide solution into the mixed solution, adjust the pH to alkaline, after a period of reaction, the solution turned golden brown, and the reaction mixed solution was dialyzed to remove unreduced silver ions , the carboxymethyl chitosan-silver complex was obtained by vacuum freeze-drying, wherein the loading of nano-silver was about 12% of the total weight of the complex.

[0052] All other experimental raw materials were obtained through conventional commercial purchases.

[0053] 2. Performance test

[0054] (1) Mechanical performance test: test according to the method of GB / T1040.1-2006.

[0055] (2) Degradation performance test: the soil burial method is use...

Embodiment 1

[0059] An antibacterial and puncture-resistant biodegradable packaging bag, the packaging bag is made of the following raw materials in parts by weight: 60 parts of PLA, 30 parts of PBAT, 15 parts of modified corn starch, 3 parts of hydroxy-terminated lactic acid oligomers, containing ring 2 parts of vinyl polymer of oxygen group, 0.6 part of 2,2'-(1,3-phenylene)-bisoxazoline, 0.6 part of diphenylmethane diisocyanate, carbon nanotube-carboxymethyl chitosan 12 parts of sugar-silver complex;

[0060] The preparation method of above-mentioned PLA / PBAT biodegradable packaging bag, comprises the following steps:

[0061] (1) modifying cornstarch to prepare modified starch for subsequent use;

[0062] (2) vacuum-dry PLA, PBAT and modified cornstarch at 60°C for 2 hours;

[0063] (3) Add the dry raw materials in step (2) into a high-speed mixer, and then add hydroxy-terminated lactic acid oligomers, vinyl polymers containing epoxy groups, 2,2'-(1,3-phenylene) - bisoxazoline, dipheny...

Embodiment 2

[0066] An antibacterial and puncture-resistant biodegradable packaging bag, the packaging bag is made of the following raw materials in parts by weight: 90 parts of PLA, 40 parts of PBAT, 20 parts of modified corn starch, 4 parts of hydroxy-terminated lactic acid oligomers, containing ring 2 parts of vinyl polymer of oxygen group, 0.8 part of 2,2'-(1,3-phenylene)-bisoxazoline, 0.4 part of diphenylmethane diisocyanate, carbon nanotube-carboxymethyl chitosan Sugar-silver complex 15 parts.

[0067] The specific preparation steps are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| grafting amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com