Sample pretreatment and detection method for detecting aromatic amine reduced by azo dye

A sample pretreatment and azo dye technology, which is applied in the sample pretreatment method and detection field, can solve the problems of sample destruction, reductant heating, mass spectrometry detection, etc., to improve detection accuracy, strong mass spectrometry compatibility, and realize Effects of Mass Spectrometry Imaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

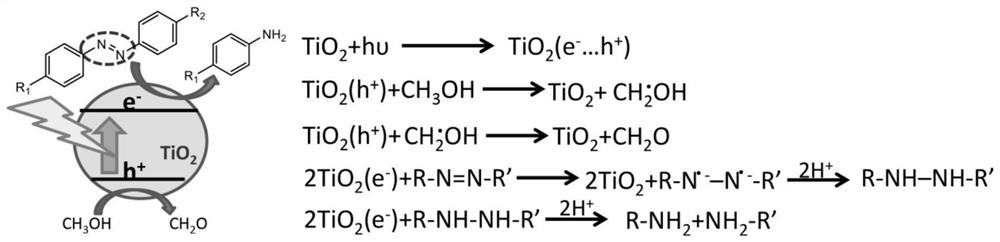

Method used

Image

Examples

Embodiment 1

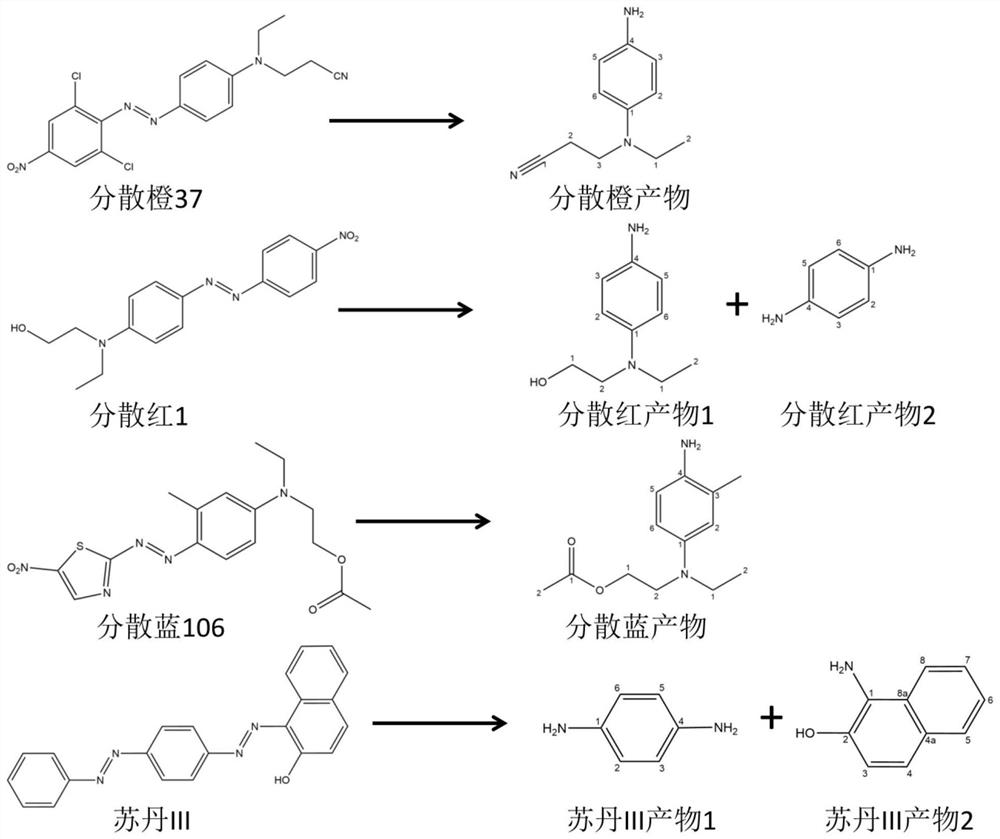

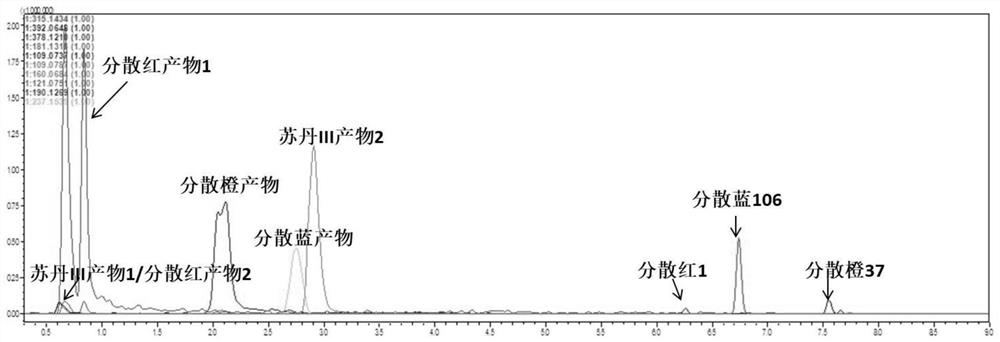

[0050] Example 1: Photocatalytic azo reduction decomposition using different reducing agents in a homogeneous solution to produce aromatic amines

[0051] 1) Photocatalytic reduction: Four reducing solutions were used, namely: 1mM methanolic solution of sodium dithionite, methanol solution of 1mM sodium sulfite, mixed methanol solution of 0.5mM sodium dithionite and 0.5mM sodium sulfite, and pure methanol. Azo dyes (Disperse Red 1, Disperse Blue 106, Disperse Orange 37, and Sudan III) were added to the four solutions to 30 μg / mL, respectively. Finally, 1.6 g / L titanium dioxide nanoparticles (5 nm) were added to the solution to obtain a dispersed solution. The solution was irradiated under a mercury lamp filtered at 356 nm for 30 min, and the current of the mercury lamp was kept at 8 mA and the irradiation distance was 10 cm.

[0052] 2) Collection of sample solution: centrifuge the titanium dioxide dispersion solution after irradiation at 8000 rpm for 10 min in a centrifuge. ...

Embodiment 2

[0055] Example 2: Reaction time curve of aromatic amine produced by photocatalytic (356nm wavelength) reduction decomposition of azo in homogeneous solution

[0056] 1) Photocatalytic reduction: 1 mM methanol solution of sodium sulfite and pure methanol were used as reducing reagents. The light reaction time is 5s, 10s, 30s, 1min, 2min, 5min, 10min, 30min, 60min. Other reducing conditions are with embodiment 1.

[0057] 2) Collection of sample solution: same as in Example 1.

[0058] 3) Liquid chromatography-mass spectrometry analysis: the same as in Example 1.

[0059] 4) Result analysis: the change curve of the product signal of different azos with the reaction time is as follows: Figure 5 shown. It can be seen from the results that the reaction rates of the two photocatalytic systems are basically similar, and for Sudan III, the reaction rate of the system without the inorganic reducing agent is even faster. And from the point of view of the repeatability of the react...

Embodiment 3

[0060] Example 3: Comparison of the reaction time curve of photocatalytic (200-400nm wavelength passband) azo reduction decomposition to produce aromatic amine in homogeneous solution and traditional chemical reaction

[0061] 1) Photocatalytic reduction: pure methanol was used as the reducing agent. The light reaction time is 5s, 10s, 30s, 1min, 2min, 5min, 10min, 30min, 60min. The solution was irradiated under a mercury lamp without a filter, and the current of the mercury lamp was kept at 8mA and the irradiation distance was 10cm. Other reducing conditions are with embodiment 1.

[0062] 2) Traditional chemical reduction: 20 mM sodium dithionate-pH 5 citric acid buffer (0.06 mol / L) was used as the reducing agent. The four azos were likewise added to the solution to 30 ppm. The solution was placed in a water bath and heated at 70°C for different times (1 min, 5 min, 10 min, 30 min, 60 min). After cooling, take it out and wait for liquid mass analysis.

[0063] 3) Collec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap