Preparation method of carbon-loaded potassium vanadate and application of carbon-loaded potassium vanadate in potassium ion battery

A technology of potassium vanadate and potassium ions, which is applied in the field of preparation of carbon-supported potassium vanadate, can solve problems such as structural transformation, difficulty in realizing effective carbon loading, poor material rate performance, etc., and achieve mass transfer resistance reduction and material effective capacity Improvement, the effect of many reactive sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (NH 4 VO 3 Preparation of KVO by precursor method x @C)

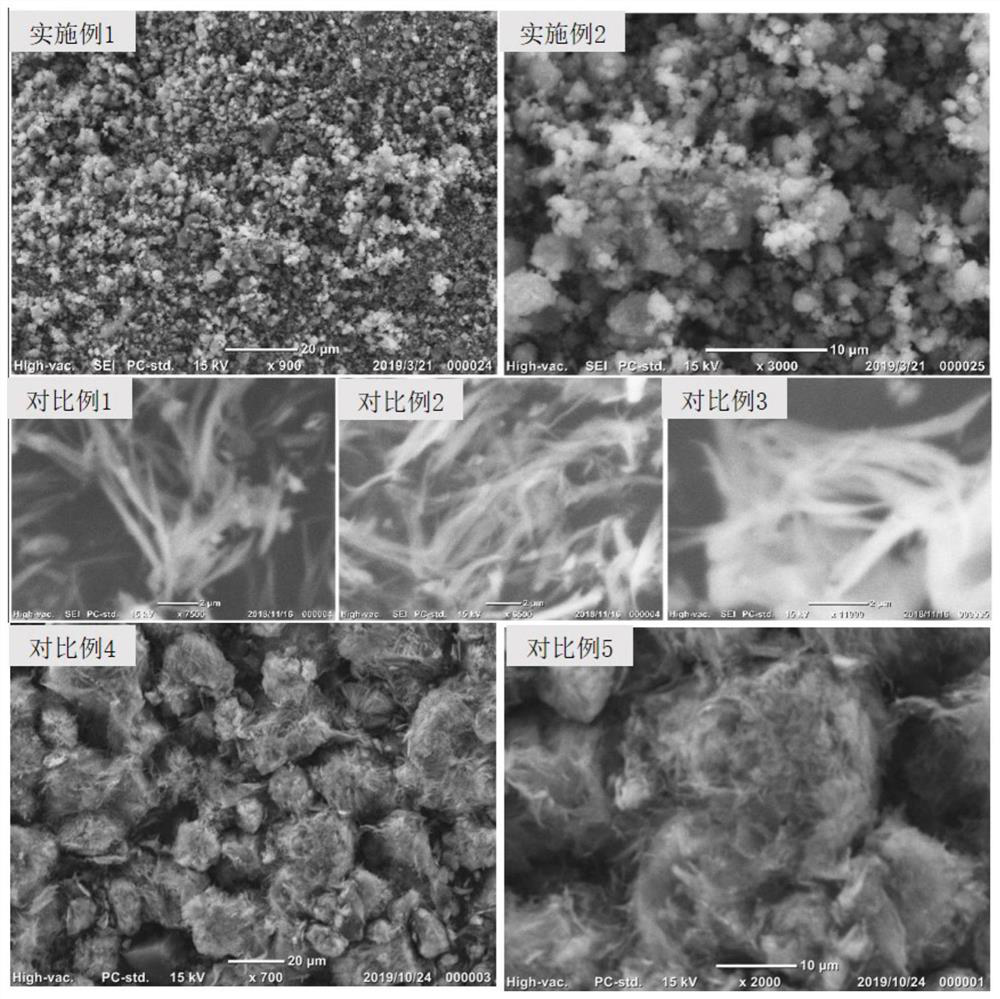

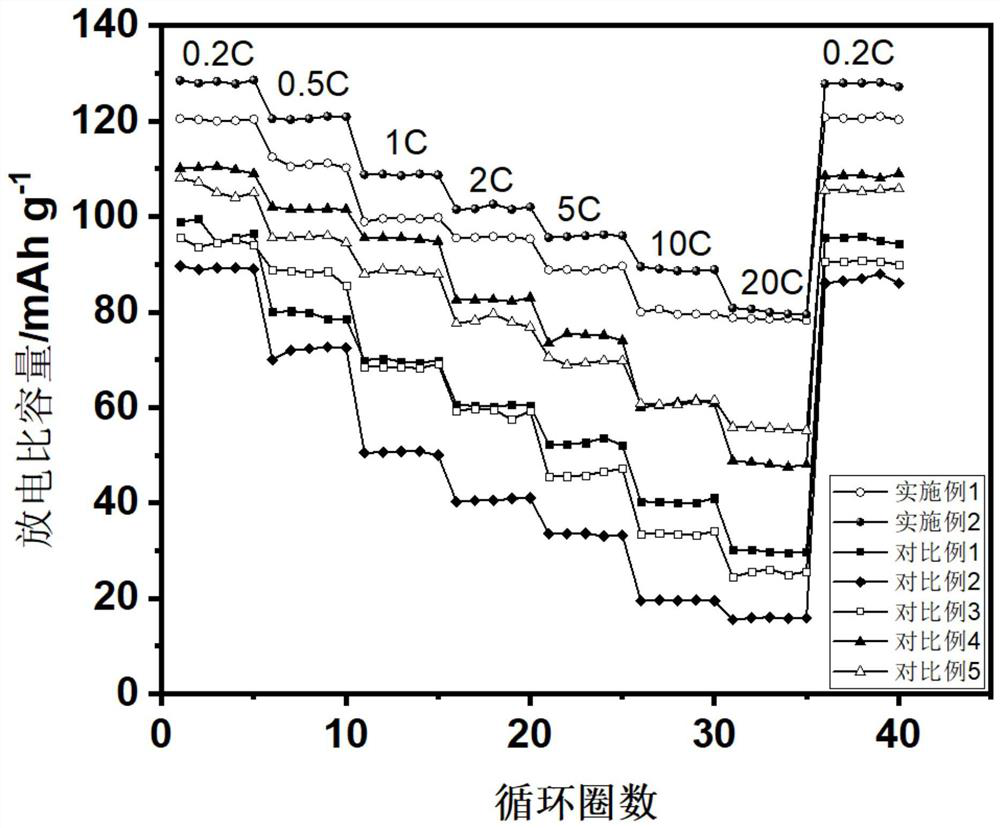

[0038] Weigh 0.5850g NH 4 VO 3Add 0.6303g of oxalic acid dihydrate to a 200mL beaker, add 100ml of deionized water, heat in a water bath at 85°C and stir for 1 hour to obtain a dark blue solution, continue stirring for 4 hours until 20mL of gel is obtained, and dry the resulting mixture in a vacuum oven at 120°C 12h, the obtained solid powder was pre-carbonized at 350°C for 5h in an argon atmosphere, and sintered at 750°C for 8h. The obtained sample was transferred into a 100mL beaker, 3.72g of potassium chloride was weighed and 25mL of deionized water was added, and stirred at room temperature for 72h. The resulting mixture was centrifuged to remove the supernatant, washed 3 times with deionized water and ethanol and centrifuged, and the obtained gray-black powder was dried in a vacuum oven at 120°C for 12 hours to obtain the final product KVO x @C, the particle size range of 200-400nm is characterized by S...

Embodiment 2

[0040] (V 2 o 5 Preparation of KVO by precursor method x @C)

[0041] Weigh 0.4550g V 2 o 5 Add 0.6303g oxalic acid dihydrate into a 200mL beaker, add 100ml deionized water, heat in a water bath at 85°C and stir for 1h to obtain a dark blue solution, continue stirring for 4h until 20mL of gel is obtained, and place the resulting mixture in a vacuum oven at 120°C Dry for 12 hours, pre-carbonize the obtained solid powder at 350°C for 5 hours in an argon atmosphere, sinter at 750°C for 8 hours, transfer the obtained sample into a 100mL beaker, weigh 3.72g of potassium chloride and add 25mL of deionized water, and stir at room temperature for 72h , the resulting mixture was centrifuged to remove the supernatant, washed 3 times with deionized water and ethanol and centrifuged, and the obtained gray-black powder was dried in a vacuum oven at 120°C for 12 hours to obtain the final product KVO x @C, the particle size range of 150-300nm is characterized by SEM test.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com