Medicine and bacterium composition for treating alcoholic liver injury as well as preparation method and application of composition

A technology of alcoholic liver injury and composition, which is applied in the field of medicine, can solve the problems of low abundance and low survival rate, and achieve the effects of reducing content, reducing accumulation, and relieving inflammation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

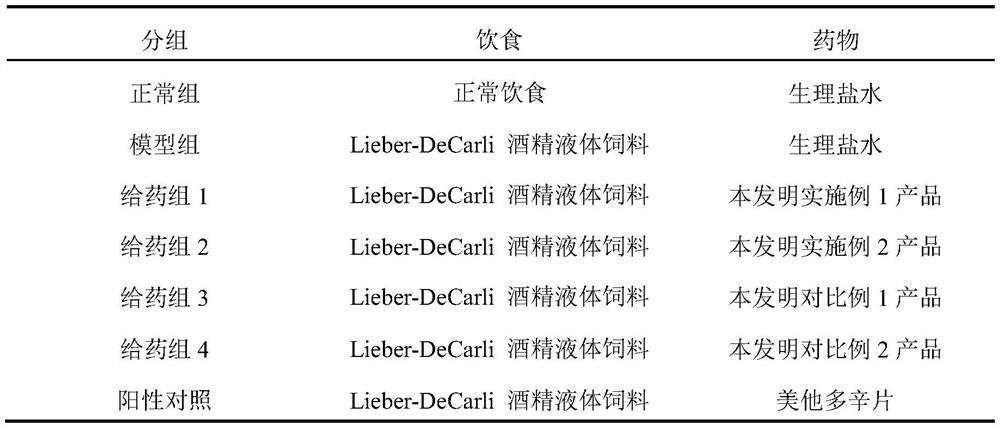

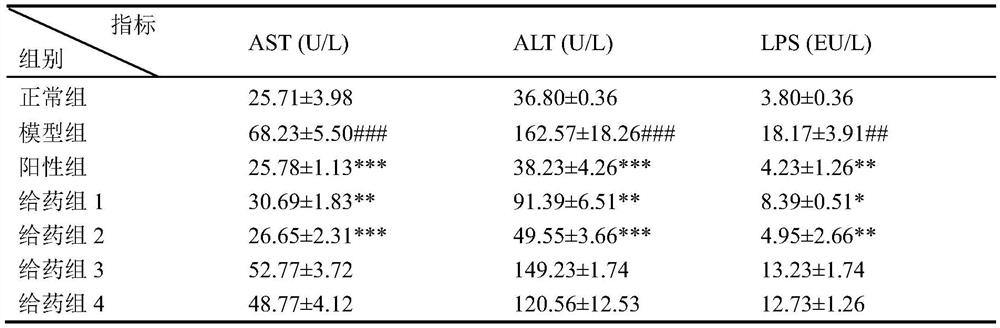

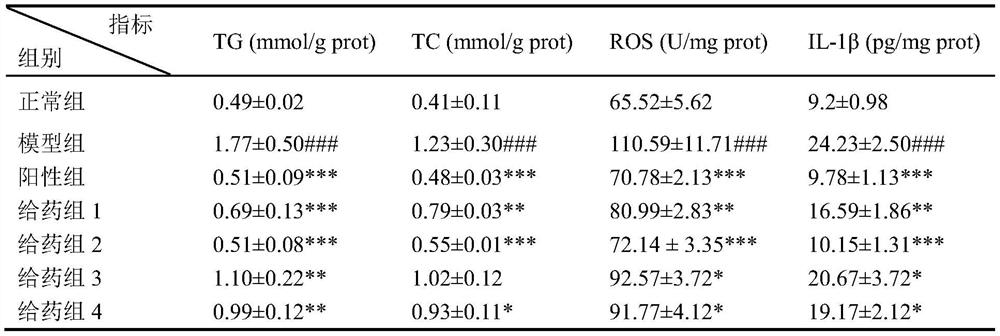

Method used

Image

Examples

Embodiment 1

[0032] (1) Preparation of Lycium barbarum puree: The high-quality Lycium barbarum was pulverized by ultrafine pulverization method, the speed of ultrafine pulverizer was 340r / min, the ball-to-material ratio was 7, and the pulverization time was 2h to obtain Lycium barbarum powder. Then add 40% water of wolfberry powder mass for mixing and beating, and sterilize at 110°C for instant high temperature to obtain wolfberry puree;

[0033] (2) Preparation of Akkermansia Muciniphila bacteria: According to the HACCP quality system, the bacteria were cultivated using a food-grade medium, and fermented under anaerobic conditions at 37° C. for 40 hours to obtain Akkermansia Muciniphila bacteria for use;

[0034] (3) Preparation of fruit pulp: wash the fruit raw materials twice or take the pulp, blueberry, kiwi fruit and apple are mixed according to the mass ratio of 8:6:3 for beating, and 0.2% of the total mass of the pulp is added to the pulp after beating Cellulase and 0.25% pectinase,...

Embodiment 2

[0041] (1) Preparation of Lycium barbarum puree: Fresh Lycium barbarum fruit was washed, directly beaten, and sterilized at 110°C to obtain Lycium barbarum puree;

[0042] (2) Preparation of Akkermansia Muciniphila bacteria: According to the HACCP quality system, the bacteria were cultivated using a food-grade medium, and fermented under anaerobic conditions at 37° C. for 40 hours to obtain Akkermansia Muciniphila bacteria for use;

[0043] (3) Pretreatment of fruit raw materials: after washing the fruit raw materials twice, take the pulp, mix blueberries, kiwis and apples according to the mass ratio of 8:6:4 for beating, and add 0.2% fiber of the total mass of pulp to the pulp after beating Sulfase and 0.25% pectinase, the enzymolysis temperature is 50-55°C, and the enzymolysis time is 2-2.5h. After colloidal grinding, fresh fruit pulp is obtained, and the fresh fruit pulp is filtered, and sterilized at 110° C. to obtain clarified fruit juice for later use;

[0044] (4) Prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com