Method for treating algae-containing sludge water by using oxidation flocculation precipitation combined process

A technology of combined process and treatment method, which is applied in the field of treatment of algae-containing muddy water by the combination process of oxidation flocculation and sedimentation, can solve the problems of high input cost, achieve the effects of increasing solid content, simple treatment method, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Water body: algae-containing muddy water from water supply plant, pH=7.4, COD Mn It is 40mg / L, and the turbidity is 96NTU;

[0031] Oxidant: sodium hypochlorite; flocculant: PFS and PAM with a mass ratio of 25:1.5;

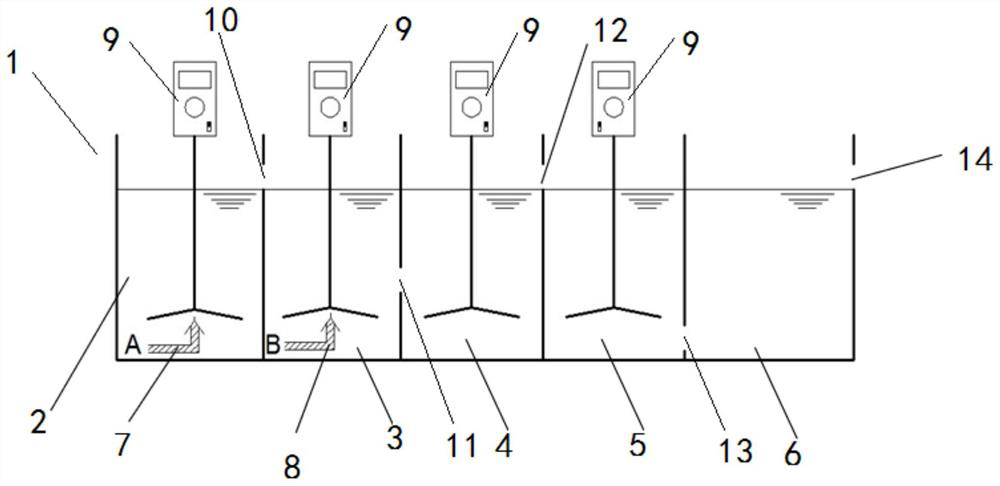

[0032] The algae-containing sludge discharge water from the water supply plant is treated with the oxidation flocculation-sedimentation combined reactor 1, and the treatment method is as follows:

[0033] S1: Put the algae-containing sludge discharge water (water body) in the oxidation pool 2, add sodium hypochlorite to the oxidation pool 2 according to the dosage of 0.3ml / L, the effective content of sodium hypochlorite is 5%, and the sodium hypochlorite is added from the oxidant dosing tube 7 Add; open the stirrer 9, the stirring speed is 350r / min, and the stirring time is 10min;

[0034] S2: The oxidized effluent flows into the mixing tank 3 by itself, and the flocculant is added to the mixing tank 3 according to the ratio of the weight volume ratio of ...

Embodiment 2

[0039] Water body: algae-containing muddy water from water supply plant, pH=7.4, COD Mn It is 36mg / L, and the turbidity is 108NTU;

[0040] Oxidant: Chlorine; Flocculant: PAC;

[0041] The algae-containing sludge discharge water from the water supply plant is treated with the oxidation flocculation-sedimentation combined reactor 1, and the treatment method is as follows:

[0042] S1: Put the algae-containing sludge discharge water (water body) in the oxidation tank 2, add chlorine gas to the sludge discharge water to be treated according to the dosing amount of 3mg / L, turn on the agitator 9, control the stirring speed to 350r / min, and contact the oxidation time 10min;

[0043] S2: The oxidized water flows into the mixing tank 3 by itself, and the flocculant is added to the mixing tank 3 according to the ratio of the weight volume ratio of the flocculant to the oxidized water of 6mg:1000ml, and the flocculant enters the mixing tank 3 from the flocculant dosing pipe 8 ; Turn ...

Embodiment 3

[0048] Water body: algae-containing muddy water from water supply plant, pH=7.4, COD MnIt is 36mg / L, and the turbidity is 108NTU;

[0049] Oxidant: Ozone; Flocculant: PAC;

[0050] The algae-containing sludge discharge water from the water supply plant is treated with the oxidation flocculation-sedimentation combined reactor 1, and the treatment method is as follows:

[0051] S1: Put the algae-containing sludge discharge water (water body) in the oxidation tank 2, add the ozone dosage of 3mg / L into the sludge discharge water to be treated, turn on the agitator 9, control the stirring speed to 350r / min, and contact oxidation The time is 10 minutes;

[0052] S2: The oxidized water flows into the mixing tank 3 by itself, and the flocculant is added to the mixing tank 3 according to the ratio of the weight volume ratio of the flocculant to the oxidized water of 6mg:1000ml, and the flocculant enters the mixing tank 3 from the flocculant dosing pipe 8 ; Turn on the stirrer 9, con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com