Polylactic acid-based photo-thermal film and preparation method thereof

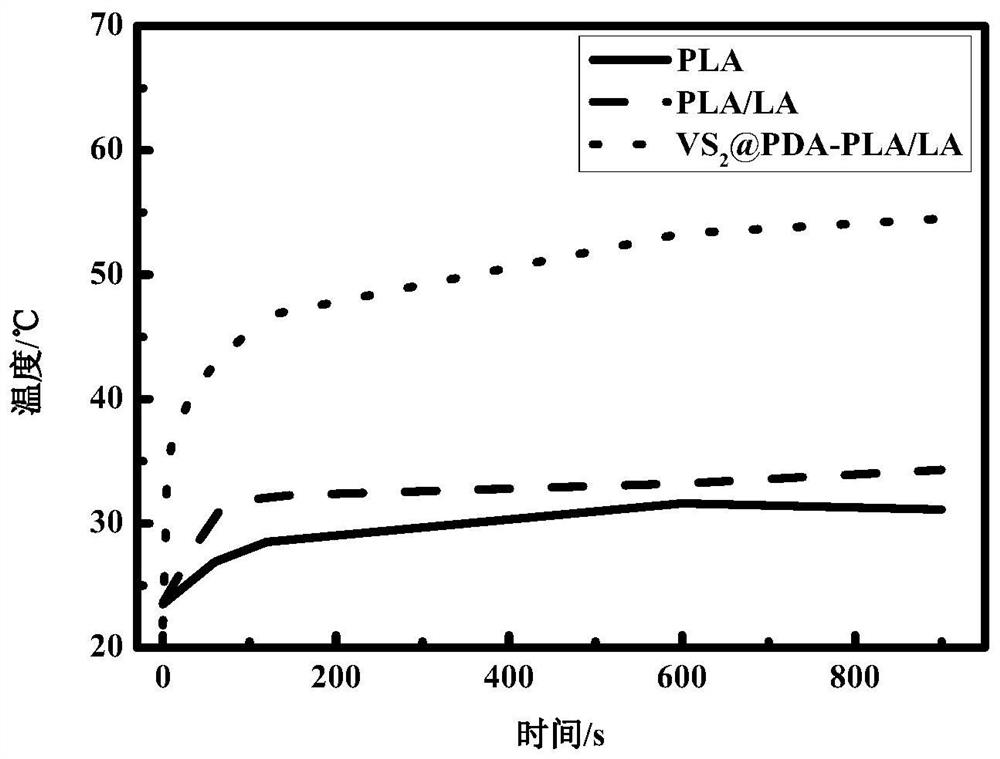

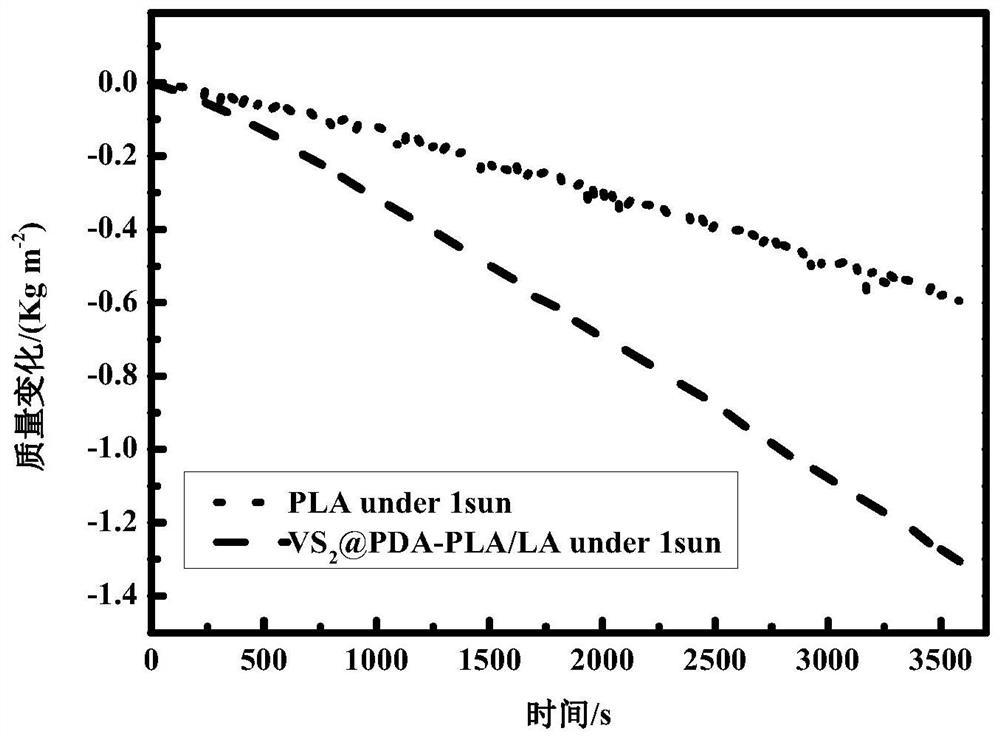

A technology based on polylactic acid and polylactic acid, which is applied in the field of polylactic acid-based photothermal film and its preparation, can solve the problems of reducing photothermal conversion efficiency, reducing light absorption performance of photothermal materials, reducing mechanical properties, etc. Effects of stability and photothermal conversion performance, excellent photothermal conversion ability, and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] (1) Preparation of polylactic acid modified lignin (LA)

[0029] 200 mg of lignin, 2.88 g of lactide and 0.0288 g of stannous octoate were added to 50 mL of anhydrous toluene, and moved to a three-necked bottle heated to 130 °C under nitrogen atmosphere and kept for 24 h. After the reaction, methanol was added to obtain a precipitate, and the solvent was removed by a vacuum filtration device, and the obtained product was dried in a vacuum oven at 60°C for 24 hours to obtain polylactic acid-modified lignin (LA).

[0030] (2) Polydopamine modified alum disulfide (VS 2 @PDA) Preparation of

[0031] 0.55 g sodium orthovanadate (Na 3 VO 4 ) and 1.13g of thioacetamide were added to 40 mL of deionized water to obtain a homogeneous solution by ultrasonication, then placed in a hydrothermal kettle and reacted at 160°C for 24 hours, washed repeatedly with deionized water, and vacuum filtered and drying to obtain alum disulfide powder (VS 2 ). Next, 0.2 g of dopamine and 0.1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

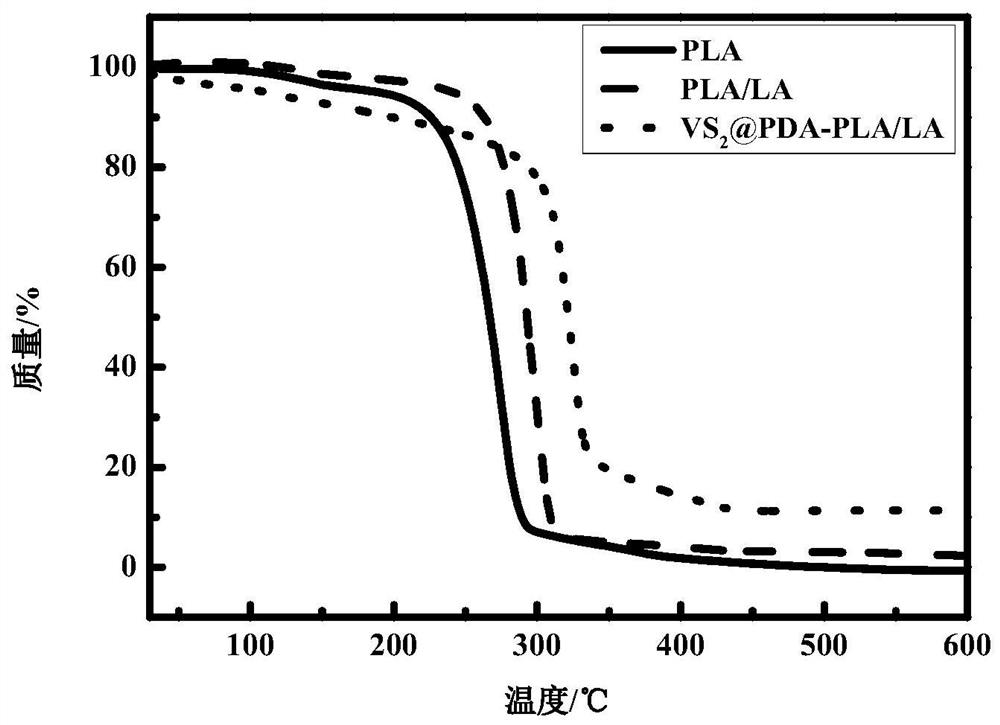

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com