Preparation process of additive premix for reducing diarrhea rate of weaned piglets and premix device in preparation process

A weaned piglet diarrhea and preparation technology, applied to bacteria used in food preparation, mixers, animal feed, etc., can solve the problems of inconvenient use, reduce the diarrhea rate of piglets during the nursery period, and cannot realize upward stir-frying, etc., and achieve improvement Stirring effect, effect of preventing accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

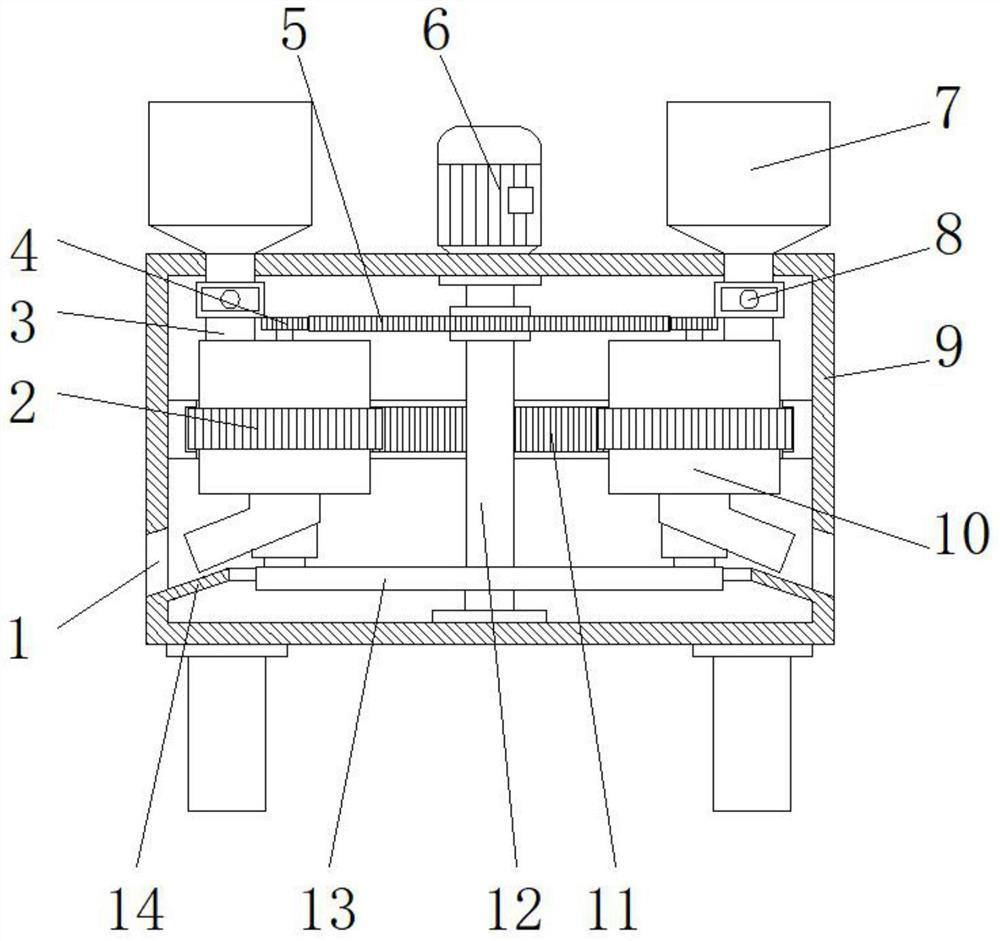

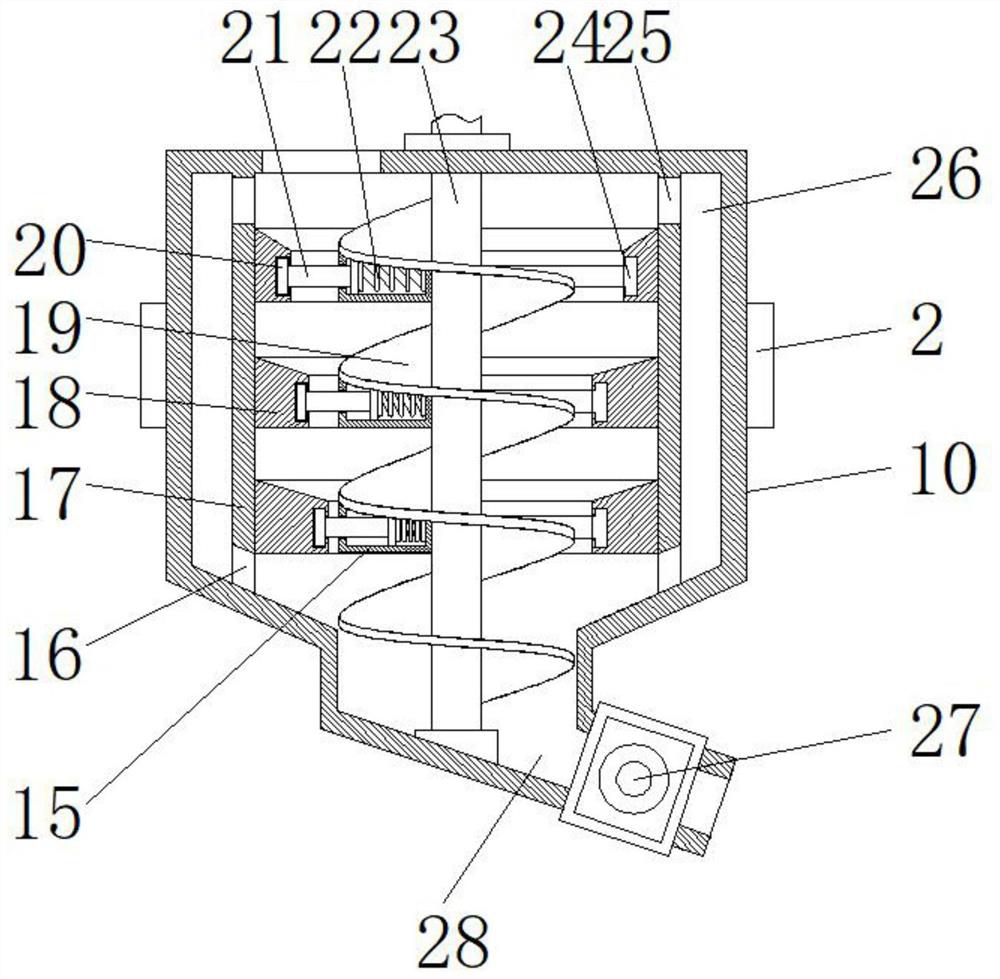

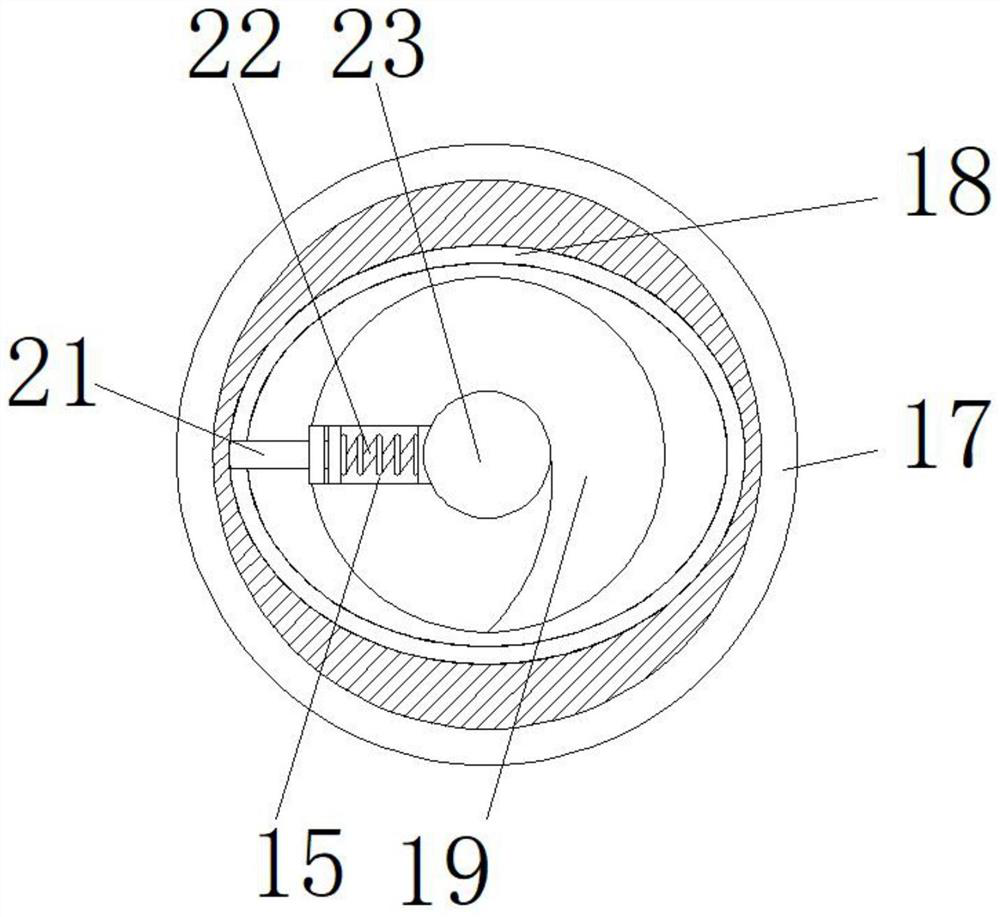

[0031] Such as Figure 1-4A kind of premixing device in the preparation process of the additive premixed material of reducing the diarrhea rate of weaned piglets shown, comprises device body 9, is arranged on the rotating disk 13 that is connected by bearing rotation at the middle position inside device body 9, is used for driving The power output mechanism rotating inside the device body 9 and the top surface of the four ends of the rotating disk 13 are rotatably connected to the mixing cylinder 10 through bearings, wherein the internal rotation of the mixing cylinder 10 is connected to the stirring mechanism and the top of the device body 9 Four storage tanks 7 corresponding to the mixing tube 10 are evenly fixed, and the bottom of the storage tank 7 is connected with a feed pipe 3, and a control valve 1 is installed on the feed pipe 3. The device body 9 A large gear ring 11 that drives the mixing cylinder 10 to rotate is fixed on the inner wall;

[0032] The power output s...

Embodiment 2

[0040] A preparation process of an additive premix for reducing the diarrhea rate of weaned piglets. The additive comprises the following components: 5-10 parts of Bacillus licheniformis, 2-5 parts of Bifidobacterium bifidum, 2-3 parts of isomaltooligosaccharide, vitamin C2 ~4 parts, 2~4 parts of taurine, 2~3 parts of glucose oxidase, 2~4 parts of lysozyme, 4~6 parts of calcium formate, 30~40 parts of montmorillonite, 30~40 parts of corn starch, its characteristics It consists of the following steps:

[0041] S1. Weigh 5 parts of Bacillus licheniformis, 4 parts of Bifidobacterium bifidum, 2 parts of isomaltooligosaccharide, 2 parts of vitamin C, 2 parts of taurine, 2 parts of glucose oxidase, 3 parts of lysozyme, and formic acid according to weight. 5 parts of calcium, 35 parts of montmorillonite, 40 parts of cornstarch for later use;

[0042] S2. Put the montmorillonite, cornstarch, calcium formate, vitamin C, taurine, and isomaltooligosaccharides weighed in S1 into the grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com