Al-Si-Cu-Ni series brazing filler metal for connecting Cu/Al connector and preparation method of Al-Si-Cu-Ni series brazing filler metal

A technology of al-si-cu-ni and brazing filler metal, which is applied in the field of Al-Si-Cu-Ni brazing filler metal connecting Cu/Al joints and its preparation, can solve the problem of base material grain growth, corrosion, and influence on joints Mechanical properties and other issues, to achieve high strength, good corrosion resistance, and improve plasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

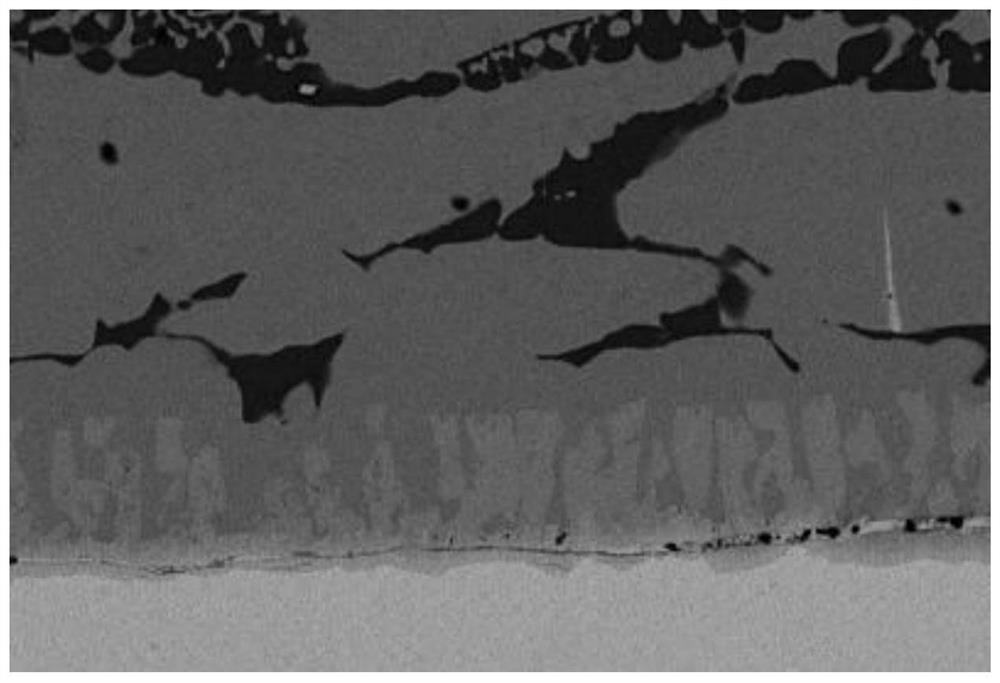

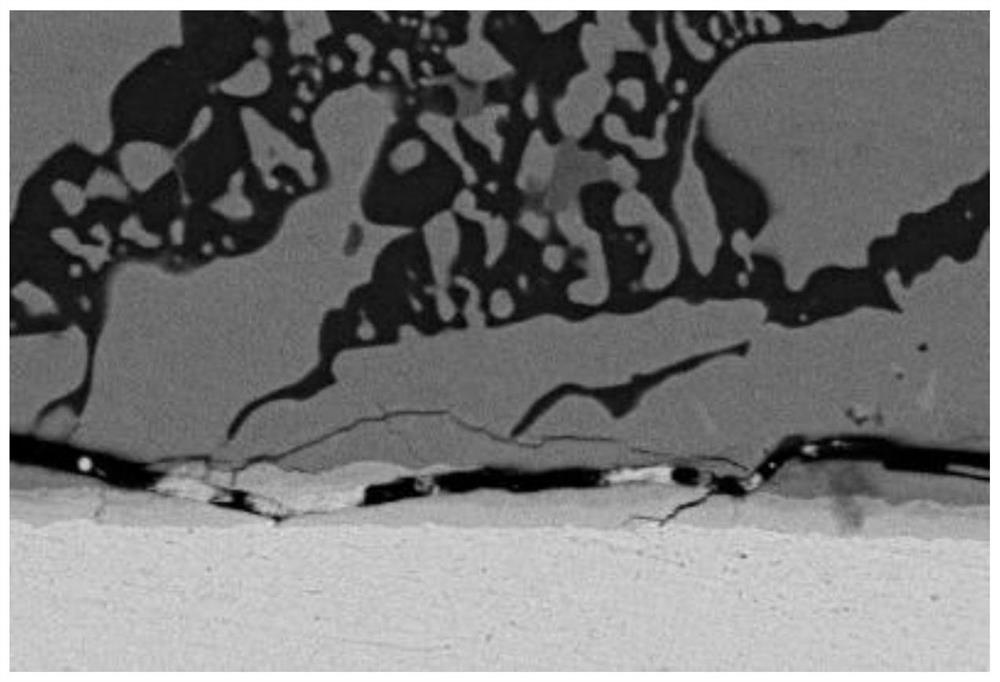

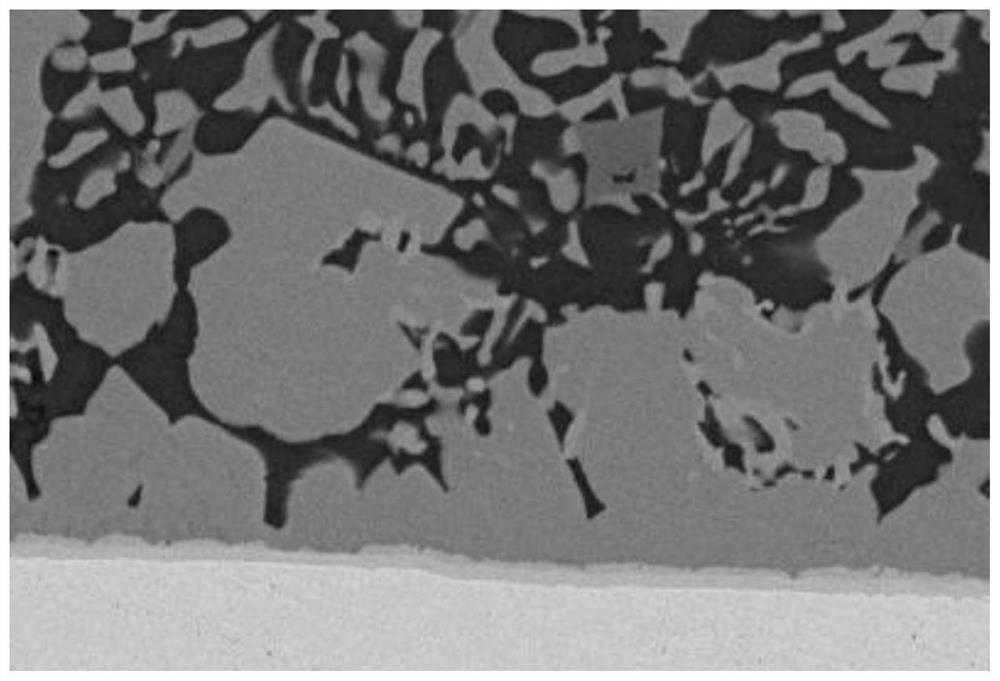

Image

Examples

Embodiment 1

[0031] A kind of composition mass ratio of the Al-Si-Cu-Ni series brazing filler metal that is used to connect Cu / Al joint is: 10% Si, 2% Cu, 2% Ni, the balance is Al, and its preparation method comprises the following steps :

[0032] 1) According to the ratio of materials used, all metal raw materials are weighed;

[0033] 2) Put all the raw materials into the crucible of the smelting furnace, and smelt under the protection of NaCl and KCl molten salt with a mass ratio of 1:1;

[0034] 3) The melting temperature is 650°C, keep warm for 30 minutes, and stir once every 10 minutes to ensure that the solder alloy composition is uniform;

[0035] 4) Casting into an ingot, rolling and drawing to make a foil to obtain an Al-Si-Cu-Ni based brazing filler metal for connecting Cu / Al joints.

Embodiment 2

[0037] A kind of composition mass ratio of the Al-Si-Cu-Ni series brazing filler metal that is used to connect Cu / Al joint is: 10% Si, 4% Cu, 2% Ni, the balance is Al; Its preparation method comprises the following steps :

[0038] 1) According to the ratio of materials used, all metal raw materials are weighed;

[0039] 2) Put all the raw materials into the crucible of the smelting furnace, and smelt under the protection of NaCl and KCl molten salt with a mass ratio of 1:1;

[0040] 3) The melting temperature is 650°C, keep warm for 35 minutes, and stir once every 10 minutes to ensure that the solder alloy composition is uniform;

[0041] 4) Casting into an ingot, rolling and drawing to make a foil to obtain an Al-Si-Cu-Ni based brazing filler metal for connecting Cu / Al joints.

Embodiment 3

[0043] A kind of composition mass ratio of the Al-Si-Cu-Ni series brazing filler metal that is used to connect Cu / Al joint is: 10% Si, 6% Cu, 2% Ni, the balance is Al; Its preparation method comprises the following steps :

[0044] 1) According to the ratio of materials used, all metal raw materials are weighed;

[0045] 2) Put all the raw materials into the crucible of the smelting furnace, and smelt under the protection of NaCl and KCl molten salt with a mass ratio of 1:1;

[0046] 3) The melting temperature is 650°C, keep warm for 35 minutes, and stir once every 10 minutes to ensure that the solder alloy composition is uniform;

[0047] 4) Casting into an ingot, rolling and drawing to make a foil to obtain an Al-Si-Cu-Ni based brazing filler metal for connecting Cu / Al joints.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com