Polypropylene fiber reinforced red mud-based geopolymer material and preparation method thereof

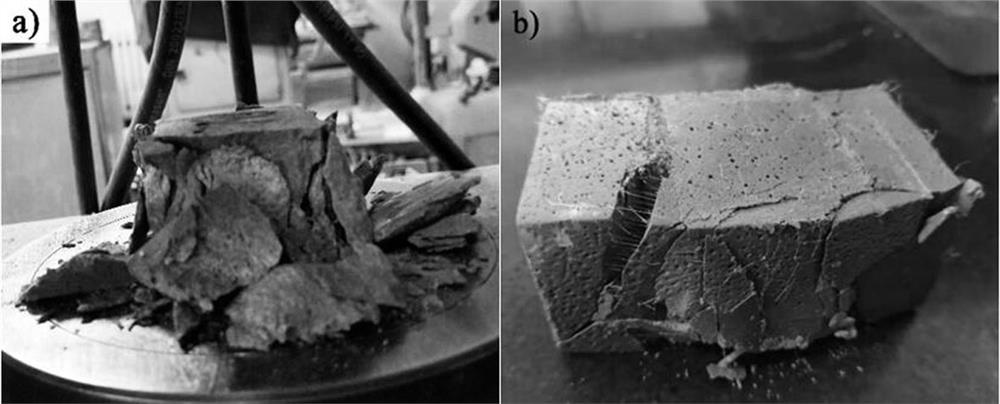

A technology of polypropylene fiber and polymer materials, applied in cement production, etc., can solve the problems of low toughness, low flexural strength, and large drying shrinkage of polymers, and achieve enhanced toughness, environmentally friendly preparation process, and brittle failure under pressure The effect of improving the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

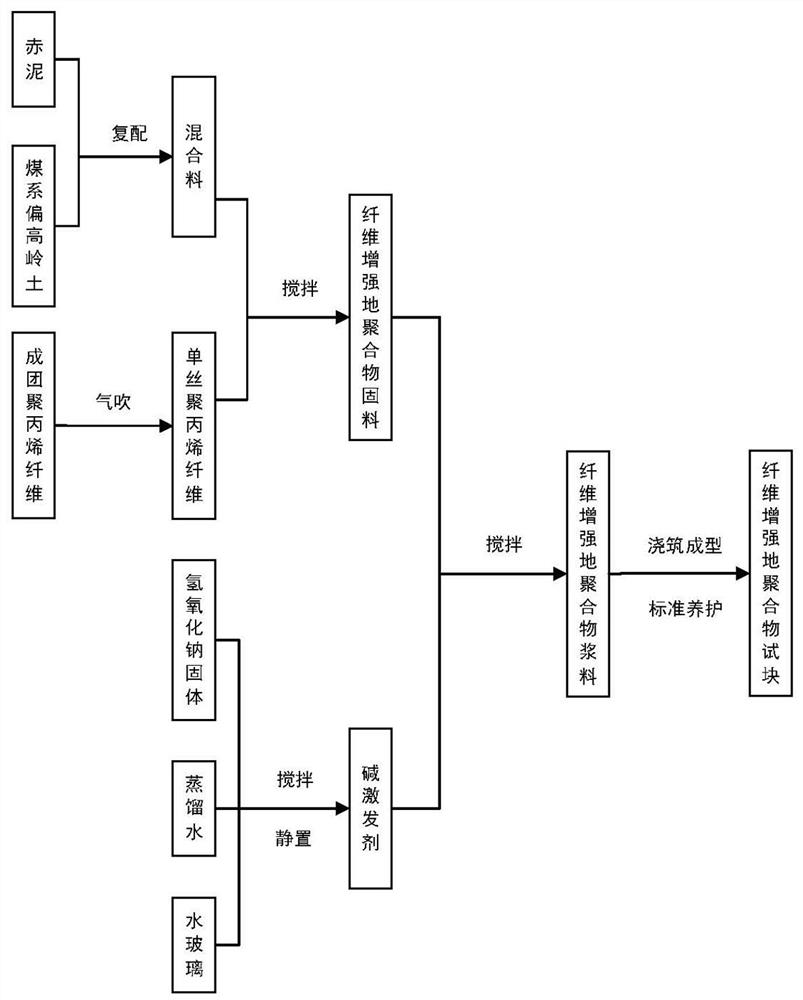

[0032] The preparation method of polypropylene fiber reinforced red mud base polymer material provided by the invention comprises the following steps:

[0033] (1) Use the high-speed gas generated by the high-pressure air gun to fully blow the agglomerated polypropylene fibers;

[0034] (2) Accurately weigh the Bayer process red mud and coal-based metakaolin according to the parts by weight, add them to the mortar mixer and stir for 2 minutes, add polypropylene fibers, and stir for 2 minutes. After the fibers are evenly dispersed, add the alkali activator and continue stirring for 3 minutes , forming a uniformly mixed fiber-reinforced geopolymer slurry;

[0035] (3) Pouring the fiber-reinforced geopolymer slurry into a 40mm×40mm×160mm steel mold, vibrating it on a vibrating table for 1min, then sealing the mold with plastic wrap and curing it at room temperature for 24 hours before demoulding;

[0036] (4) Put the demoulded fiber-reinforced geopolymer in a standard curing box...

Embodiment 1

[0042] Formula: prepare 700 parts of Bayer process red mud, 300 parts of coal series metakaolin, 70 parts of distilled water, 80 parts of sodium hydroxide, 640 parts of water glass solution, and 4 parts of polypropylene fiber. Among them, the length of the polypropylene fiber is 9mm.

[0043] Prepare the sample: Pour the mixture of Bayer process red mud and coal-based metakaolin into a mortar mixer and mix thoroughly for 2 minutes; add dispersed polypropylene fibers and stir for 2 minutes, then add alkali activator, stir for 3 minutes, and rotate at 150r / min. A uniformly mixed slurry is formed, and the slurry is packed into a steel mold of 40mm×40mm×160mm. Vibrate on a mortar vibrating table, level off with a scraper, and stand at room temperature for 24 hours to form a geopolymer cementitious material.

Embodiment 2

[0045] Formula: Prepare 700 parts of Bayer process red mud, 300 parts of coal series metakaolin, 70 parts of distilled water, 80 parts of sodium hydroxide, 640 parts of water glass solution, and 6 parts of polypropylene fiber. Among them, the length of the polypropylene fiber is 12mm.

[0046] The test block preparation and testing process are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com