Ammonium polyphosphate granular multi-component compound fertilizer with low polymerization degree and preparation method thereof

A technology of ammonium polyphosphate and low degree of polymerization, applied in ammonium orthophosphate fertilizer, urea compound fertilizer, alkaline orthophosphate fertilizer, etc., can solve the problems of high energy consumption, high production cost, increased production cost, etc. The effect of high difficulty in control, high production cost, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

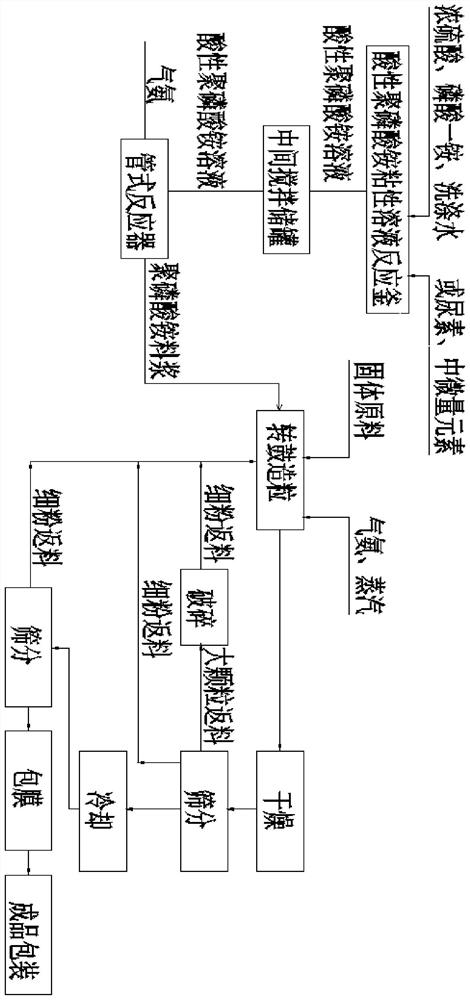

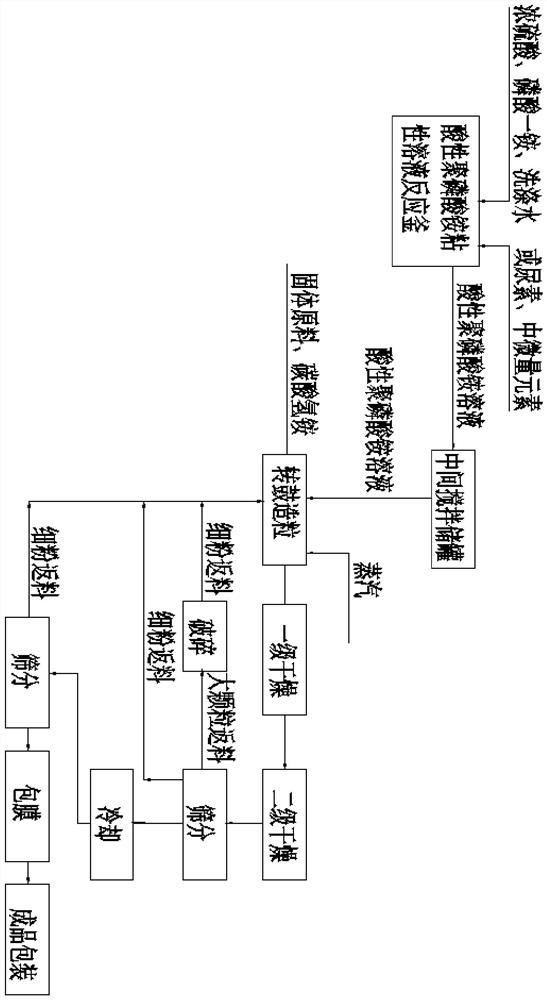

[0071] like figure 2 As shown, another preparation method comprises the following steps:

[0072] S1. Preparation of acidic ammonium polyphosphate viscous solution: Add the raw materials for preparing the acidic ammonium polyphosphate viscous solution in the formula amount into the reactor, stir and react in the reactor to form an acidic ammonium polyphosphate viscous solution, and transport it to the intermediate storage tank with stirring for waiting use;

[0073] S2. Preparation of low-polymerization-degree ammonium polyphosphate granule multivariate compound fertilizer: transport the acidic ammonium polyphosphate viscous solution into the drum granulator, and spray it on the inner material layer of the drum granulator through an atomizing nozzle. The mass ratio of acidic ammonium polyphosphate viscous solution to solid raw materials, system return material, ammonium bicarbonate polymerization granulation, and steam is added to the material layer of the granulator to adju...

Embodiment 1

[0076] A kind of low polymerization degree ammonium polyphosphate granular zinc-containing multiple compound fertilizer, comprising solid monoammonium phosphate (11-44-0) 80kg / t, solid urea (46.4-0-0) 265kg / t, solid ammonium chloride (25.4 -0-0) 400kg / t, solid potassium chloride (0-0-60) 100kg / t, acidic ammonium polyphosphate viscous solution 182kg / t, gas ammonia 17kg / t. The mass ratio of solid raw material, acidic solution, and gas ammonia is 4.64:1.0:0.09, and the mass ratio of acidic ammonium polyphosphate viscous solution to gas ammonia added to the tubular reactor is 1.0:0.05.

[0077] The preparation method of the low-polymerization-degree ammonium polyphosphate particle zinc-containing multivariate compound fertilizer comprises the following steps:

[0078] S1. Prepare an acidic ammonium polyphosphate viscous solution, stir and react according to the mass ratio of concentrated sulfuric acid, monoammonium phosphate, water, urea, and zinc sulfate as 1.0:2.0:1.0:2.0:0.07, ...

Embodiment 2

[0082] A low-polymerization degree ammonium polyphosphate granule multivariate compound fertilizer, comprising solid monoammonium phosphate (11-47-0) 235kg / t, solid ammonium chloride (25.4-0-0) 360kg / t, solid potassium chloride (0 -0-60) 250kg / t, acidic ammonium polyphosphate solution (concentrated sulfuric acid, monoammonium phosphate, water mass ratio 1.0:2.0:2.0) 225kg / t, ammonia gas 31kg / t. The mass ratio of solid raw material, acidic solution, and ammonia gas is 3.75:1.0:0.14, and the mass ratio of acidic ammonium polyphosphate viscous solution to ammonia gas added to the tubular reactor is 1.0:0.08.

[0083] The preparation method of the low-polymerization-degree ammonium polyphosphate granule multivariate compound fertilizer comprises the following steps:

[0084] S1. Prepare an acidic ammonium polyphosphate viscous solution, stir and react according to the mass ratio of concentrated sulfuric acid, monoammonium phosphate, and water at a ratio of 1.0; use.

[0085] S2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain strength | aaaaa | aaaaa |

| Grain strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com