A method for improving the performance of organic-inorganic composite materials

An inorganic composite material and composite material technology, applied in the field of composite material preparation, can solve problems such as insufficient exposure of inorganic nanoparticles, and achieve the effects of simple and environmentally friendly preparation process, improved function, and increased area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] 1. Use a permeable low-pressure plasma reactor (such as Figure 5 shown), the top is a flat electrode, and the bottom is two sets of grid electrodes, the grid electrodes have a width of 8mm-10mm, and a spacing of 1mm-2mm. The distance between the upper and lower electrodes is 2 cm, and the electrodes are covered with an insulating medium with a thickness of 0.1 to 0.2 mm. The cavity is evacuated to a background pressure of 5Pa, and the flowmeter is turned on to begin to flow Ar / O into the discharge cavity. 2 Mixed gas, Ar / O 2 The volume ratio is 1: (0.1~0.2), the total flow is 100-300sccm, and after the pressure in the discharge chamber is stabilized to 30-100Pa, set the parameters of the plasma discharge: between the upper plate electrode and the lower group of grid electrodes Apply 10MHz ~ 13.56MHz radio frequency source, power 300-400W. The discharge is regulated by a pulse switch, the frequency of the pulse switch is 80-100kHz, the width is 80us-100us, and the du...

Embodiment 2

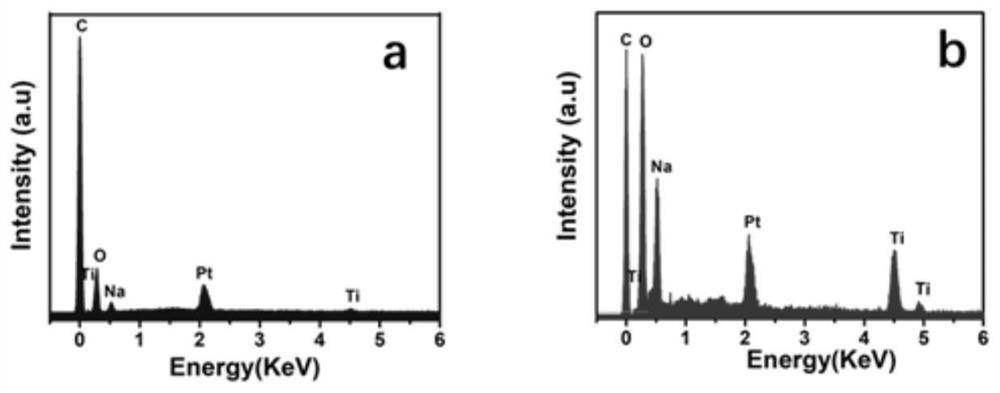

[0042] 1. The untreated and plasma treated fully matte polyester PET / TiO in Example 1 2 , after dipping and coating with 30% by weight of perfluoromethacrylate waterproof finishing agent at room temperature for 10min, and drying at 160°C for 90s. Then the fabric water and oil repellency performance test was carried out.

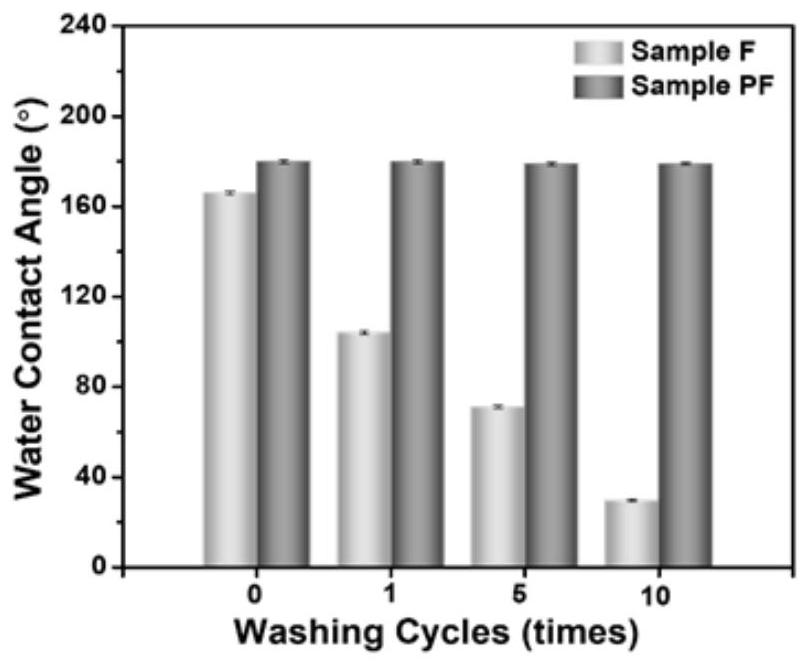

[0043] 2. According to the AATCC20 fabric spray hydrophobicity test standard method, configure standard soap solution for 10 consecutive cycles of washing at room temperature, and test the static contact angle and spray characteristics after 1, 5, and 10 cycles. The static water contact angle varies with the number of washings. Changed test results such as figure 2 shown.

[0044] 3. Fully matte polyester PET / TiO coated without plasma treatment 2 (sample F), the static contact angle to water is 160°, and the spray level is 90°. After 10 cycles of washing, the static contact angle of water drops to 40°, and the water spray level is 0°.

[0045] 4. Fully m...

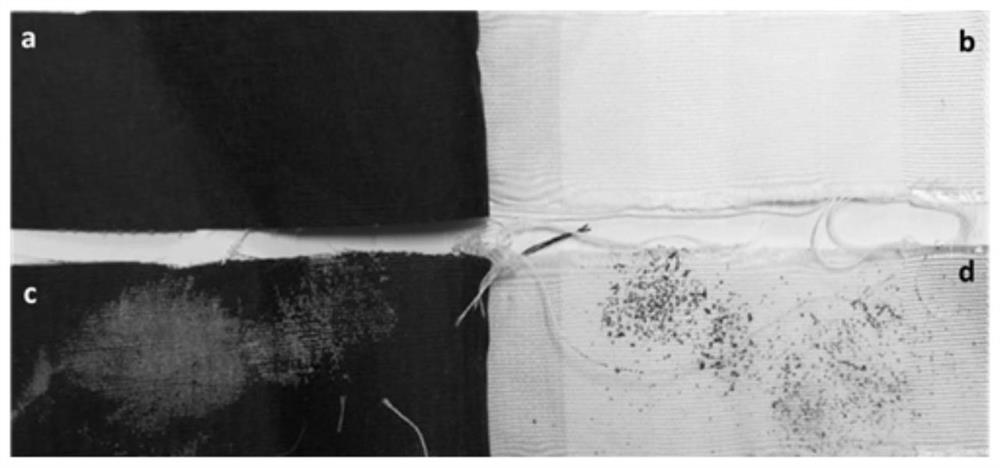

Embodiment 3

[0047] 1. The selective plasma etching treatment is specifically as follows: a low-pressure plasma reactor is used, the upper part is a flat electrode, the lower part is two sets of grid electrodes, the distance between the upper and lower electrodes is 1cm, and the width of the lower grid electrode is 6mm to 7mm. The electrodes with a spacing of 2 mm to 3 mm are covered with insulating medium with a thickness of 0.4 to 0.5 mm. The cavity is evacuated to a background pressure of 5Pa, and the flowmeter is turned on to begin to flow Ar / O into the discharge cavity. 2 Mixed gas, Ar / O 2 The volume ratio is 1:(0.3~0.5), the total flow is 130-150sccm, and after the pressure in the discharge chamber is stabilized at 50-80Pa, the plasma with a frequency of 2-5MHz and a power of 100-300W is applied to the upper parallel plate electrode and the lower On a set of grid electrodes, pure PET polyester fabric and semi-matte polyester PET / TiO 2The fabrics were processed through the plasma di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com