Preparation method of gradient structure copper-based composite electric contact material

An electrical contact material, copper-based composite technology, which is used in equipment for manufacturing conductive/semiconducting layers, cable/conductor manufacturing, circuits, etc., can solve the problem of limited surface hardness of titanium bronze materials The application range of high-conductivity and high-elasticity components can achieve the effect of reducing friction coefficient, improving comprehensive performance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

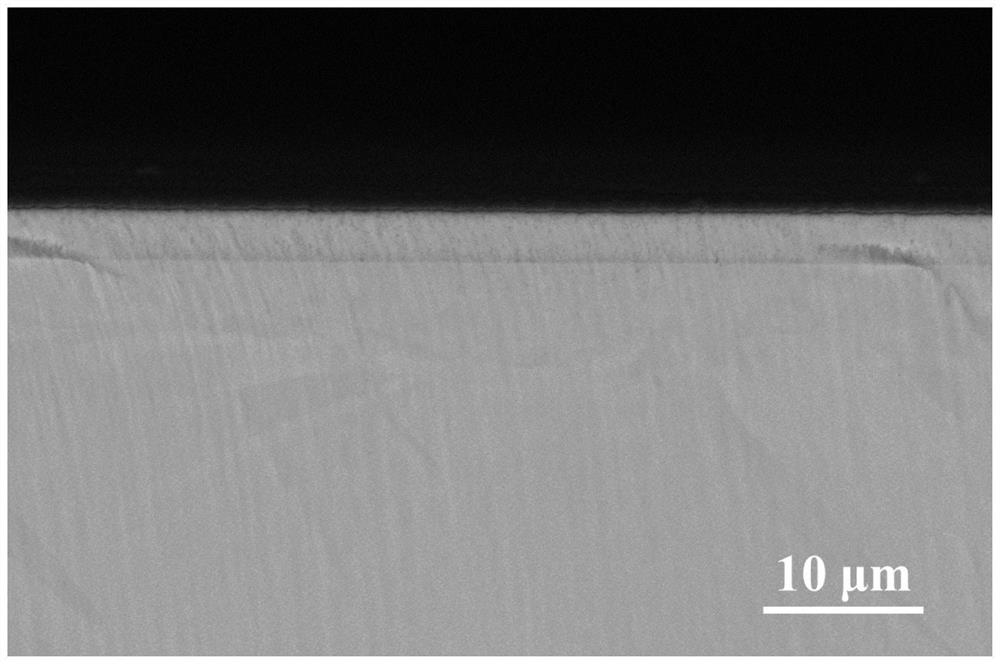

[0027] A method for preparing a gradient structure copper-based composite electrical contact material: the step of selecting the copper alloy is QTI3.5 substrate (Ti3.5-4.0 wt%, the sum of the total impurities ≤ 0.5%, the margin is Cu), QTI3.5 matrix conducts mechanical polishing treatment and washing 10 minutes in acetone solution, and is easily washed in anhydrous ethanol solution for 10 min, and the pretreatment QTI3.5 substrate is placed on top of the closed cavity for mechanical polishing treatment, and the bottom is placed oxidation The number of zirconium balls is 180, the steel ball is 4 mm, the treatment time is 30 min, the vibration frequency is 45 Hz, and the mechanically polished QTI3.5 matrix is placed in acetone solution to ultrasonically cleaning 10 min, and cleaning 5S in a mixed acid solution, mix Acid solution quality ratio H 2 SO 4 : Hno 3 : Ultra-pure water is 5: 3: 2; the handled QTI3.5 matrix is sandwiched on the reaction magnetopolymer sputter system sam...

Embodiment 2

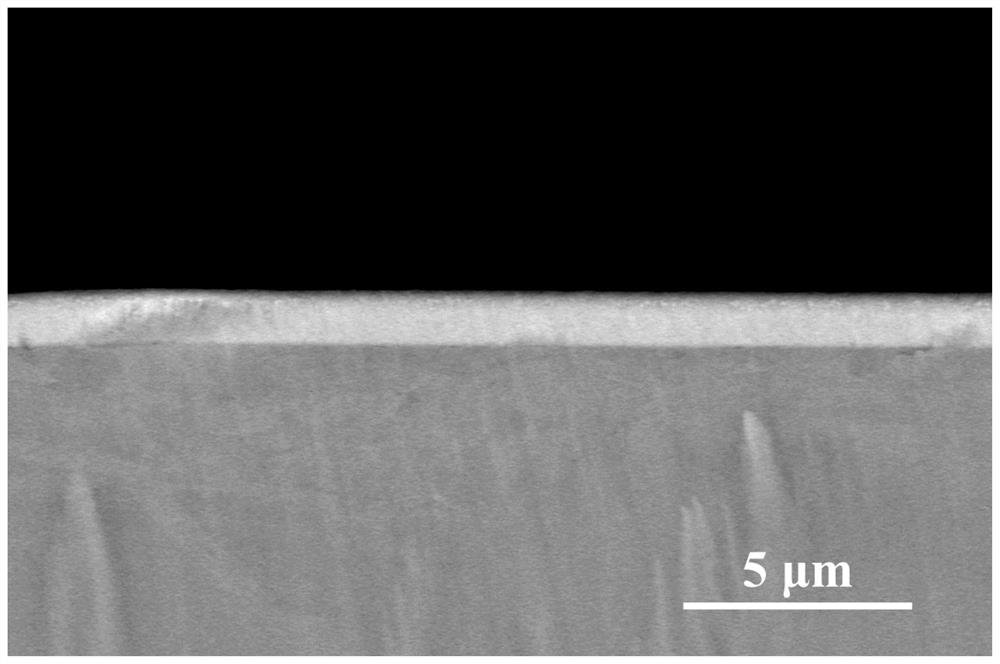

[0031] A method for preparing a gradient structure copper-based composite electrical contact material, using the same raw materials and preparation processes in Example 1, the industrial pure titanium TA1 target radio power supply and the Ni-Cu-RE target radio power supply Changed to 100 min; take a cross-sectional analysis of gradient composite coating, its thickness of 3 μm.

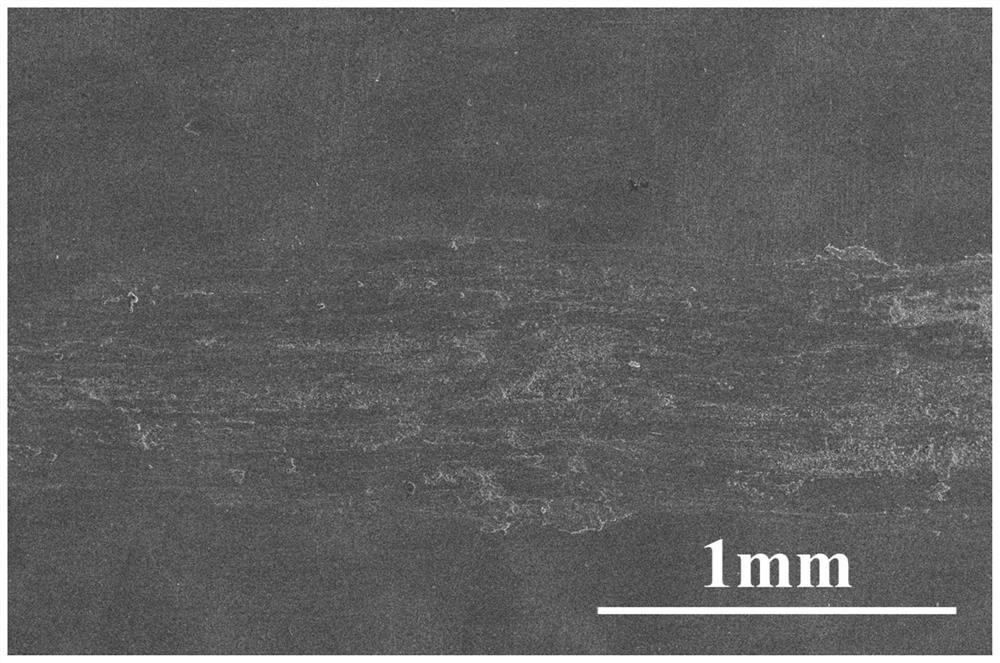

[0032] With the multi-function friction wear, the friction conditions are dry friction, the wear method is a one-way circulation slide, and the friction pair is 4mm G10 steel ball. Under the 5N load, the line speed is 10mm / s, the total motion distance is 18m, and the average friction is measured. The coefficient is 0.37, the wear rate is 0.42mm 3 / (N · m).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com