Electrostatic spinning gel fiber membrane as well as preparation method and application thereof

A silk gel fiber, electrospinning technology, applied in textiles and papermaking, fiber chemical characteristics, conjugated rayon, etc., can solve the problems of complex preparation method, complex process, high cost of large-scale production, etc. Effects of adhesion wound healing, promotion of adhesion, good hydrophilicity and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

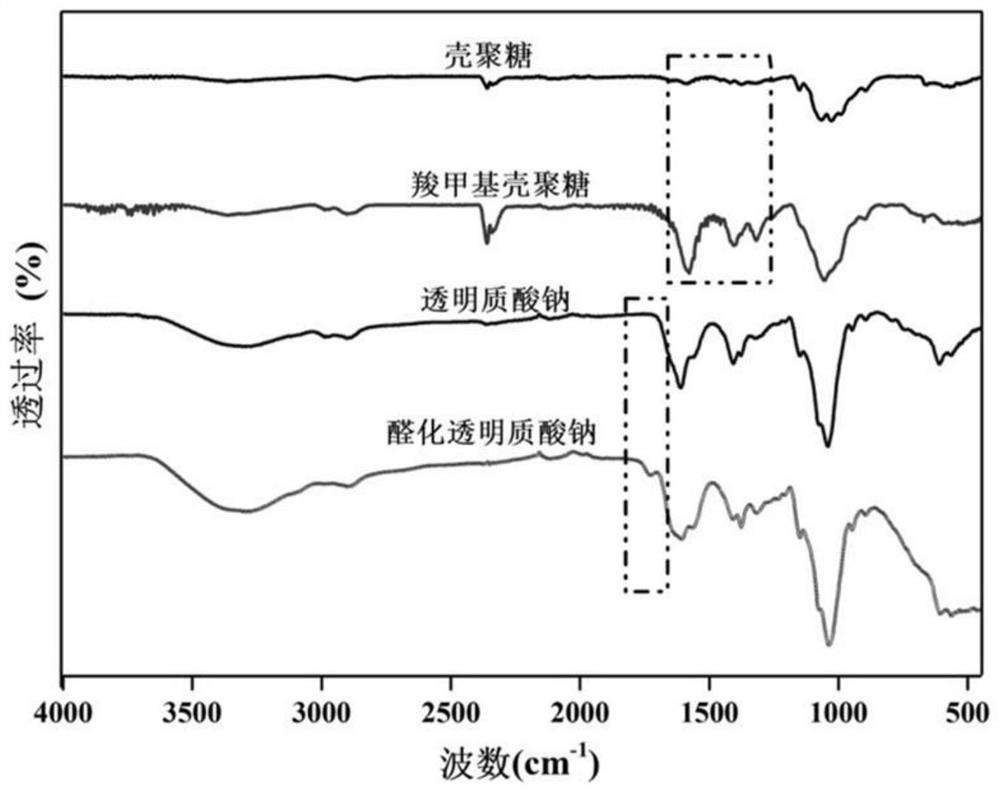

[0071] In this embodiment, an electrospinning gel fiber membrane is provided, and the preparation raw materials of the electrospinning gel fiber membrane include an electrospinning solution A and an electrospinning solution B, and the electrospinning solution A is carboxylated A mixed solution of methyl chitosan, polyvinyl alcohol and deionized water, the electrospinning solution B is a mixed solution of sodium hyaluronate, polyvinyl alcohol and deionized water.

[0072] Wherein, the carboxymethyl substitution degree of carboxymethyl chitosan is 85%, the degree of hydroformylation of sodium hyaluronate is 80%; the mass fraction of carboxymethyl chitosan in electrospinning solution A is 0.05% , the mass fraction of polyvinyl alcohol is 5%, and the rest is deionized water; the mass fraction of sodium hyaluronate hyaluronate in electrospinning solution B is 10%, the mass fraction of polyvinyl alcohol is 5%, and the rest is deionized water Water; the volume ratio of electrospinnin...

Embodiment 2

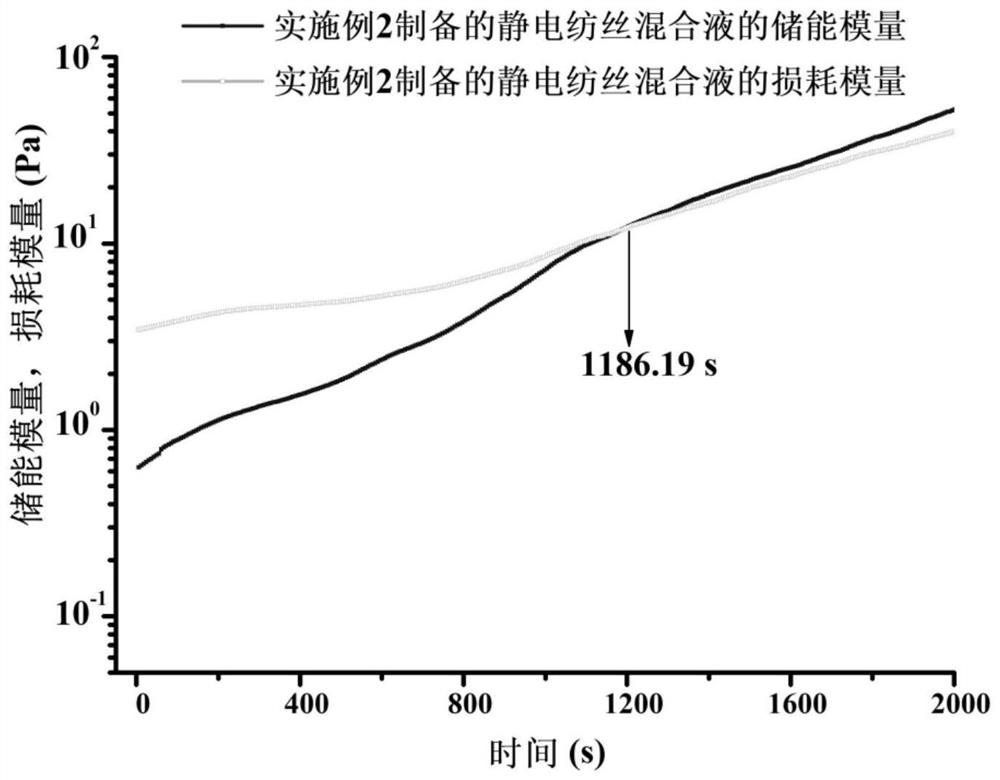

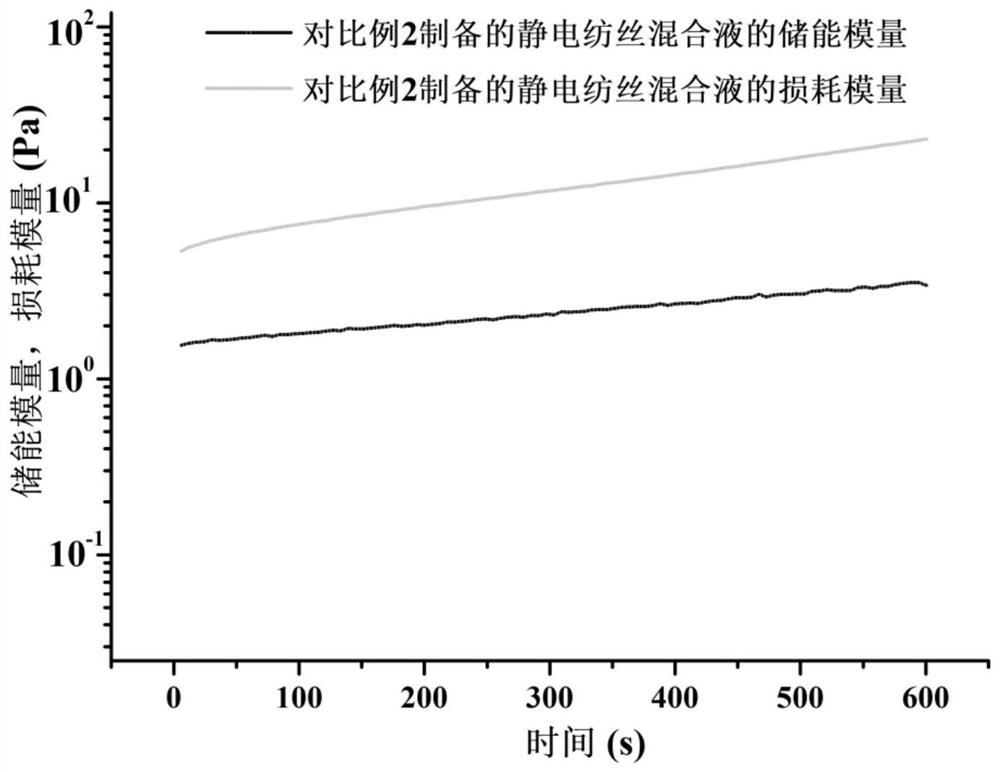

[0088] In this embodiment, an electrospinning gel fiber membrane is provided, and the preparation raw materials of the electrospinning gel fiber membrane include an electrospinning solution A and an electrospinning solution B, and the electrospinning solution A is carboxylated A mixed solution of methyl chitosan, polyvinyl alcohol and deionized water, the electrospinning solution B is a mixed solution of sodium hyaluronate, polyvinyl alcohol and deionized water.

[0089] Wherein, the carboxymethyl substitution degree of carboxymethyl chitosan is 25%, the degree of hydroformylation of sodium hyaluronate is 60%; the mass fraction of carboxymethyl chitosan in electrospinning solution A is 5%. , the mass fraction of polyvinyl alcohol is 10%, and the rest is deionized water; the mass fraction of sodium hyaluronate hyaluronate in electrospinning solution B is 5%, the mass fraction of polyvinyl alcohol is 8%, and the rest is deionized water Water; the volume ratio of electrospinning ...

Embodiment 3

[0104] In this embodiment, an electrospinning gel fiber membrane is provided, and the preparation raw materials of the electrospinning gel fiber membrane include an electrospinning solution A and an electrospinning solution B, and the electrospinning solution A is carboxylated A mixed solution of methyl chitosan, polyethylene oxide and deionized water, the electrospinning solution B is a mixed solution of sodium carboxymethyl cellulose, polyvinyl alcohol and deionized water.

[0105] Wherein, the degree of substitution of carboxymethyl chitosan of carboxymethyl chitosan is 50%, the degree of hydroformylation of sodium carboxymethyl cellulose is 40%; the mass fraction of carboxymethyl chitosan in electrospinning solution A is 10%, the mass fraction of polyethylene oxide is 15%, and the rest is deionized water; the mass fraction of sodium carboxymethylcellulose in electrospinning solution B is 10%, and the mass fraction of polyvinyl alcohol is 20%, The rest is deionized water; t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com