Filler type biological rotating disc and method for ammonia nitrogen conversion based on filler type biological rotating disc

A biological turntable, filler technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems of short service life, low treatment efficiency, poor film hanging performance, etc. Life, improve processing efficiency, increase the effect of filling amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

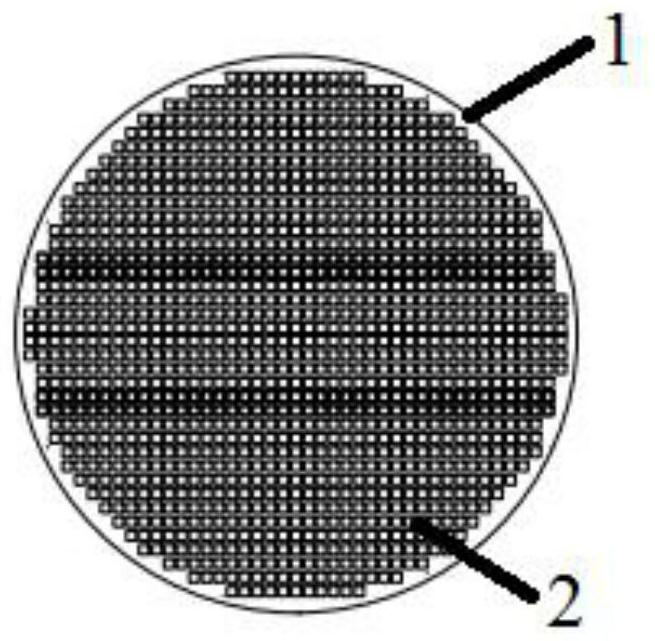

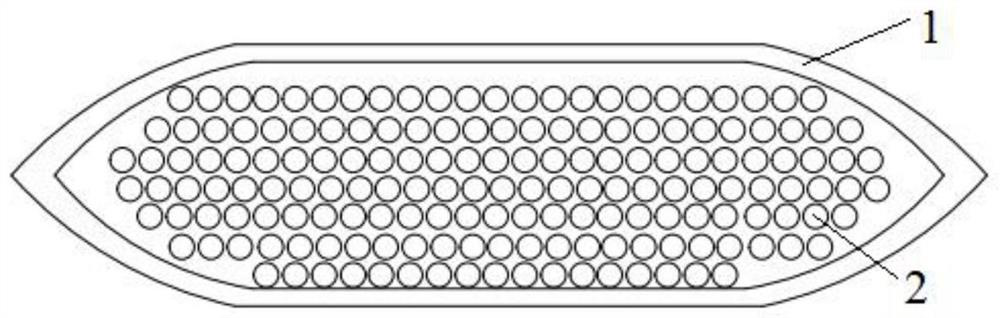

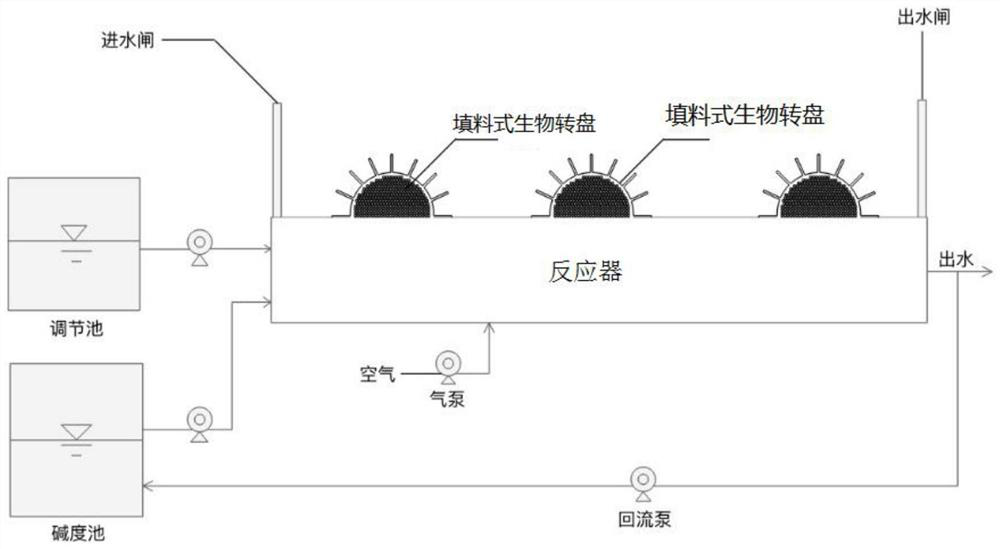

[0064] The packing type biological turntable includes a rotating shaft, a pumping plate and a packing frame; the packing frame is formed by interlocking two discs containing meshes; the packing frame has a hollow structure; the rotating shaft passes through the packing frame center, and drive the stuffing frame to rotate around the axis of rotation.

[0065] Filler is filled in the hollow structure of described filler frame; Described filler is natural zeolite, and the particle diameter of described natural clinoptilolite is 4mm; The diameter of the mesh of described disk is 0.85mm; The setting of described mesh The density is 20 mesh; the packing density of the filler is 80%.

[0066] 1. The natural clinoptilolite is added to the packed biological turntable, and the total volume of the filler accounts for 30% of the volume of the reaction tank; the packed biological turntable is cultivated by continuous water inflow, the ammonia nitrogen concentration of the simulated water i...

Embodiment 2

[0071] The packing type biological turntable includes a rotating shaft, a pumping plate and a packing frame; the packing frame is formed by interlocking two discs containing meshes; the packing frame has a hollow structure; the rotating shaft passes through the packing frame center, and drive the stuffing frame to rotate around the axis of rotation.

[0072] The filler is filled in the hollow structure of the packing frame; the filler is natural clinoptilolite, and the particle diameter of the natural clinoptilolite is 4mm; the diameter of the mesh of the disc is 0.85mm; The setting density of the mesh is 20 meshes; the filling density of the filler is 80%.

[0073]1. The natural clinoptilolite is added to the packed biological turntable, and the total volume of the filler accounts for 30% of the volume of the reaction tank; the packed biological turntable is cultivated by continuous water inflow, the ammonia nitrogen concentration of the simulated water is 50mg / L, and the HRT...

Embodiment 3

[0078] The packing type biological turntable includes a rotating shaft, a pumping plate and a packing frame; the packing frame is formed by interlocking two discs containing meshes; the packing frame has a hollow structure; the rotating shaft passes through the packing frame center, and drive the stuffing frame to rotate around the axis of rotation.

[0079] The hollow structure of the filler frame is filled with filler; the filler is natural clinoptilolite, and the particle diameter of the natural clinoptilolite is 4mm; the diameter of the mesh of the disc is 0.85mm; the disc The setting density of the mesh is 20 meshes; the packing density of the filler is 80%.

[0080] 1. The natural clinoptilolite is added to the packed biological turntable, and the total volume of the filler accounts for 30% of the volume of the reaction tank; the packed biological turntable is cultivated by continuous water inflow, the ammonia nitrogen concentration of the simulated water is 50mg / L, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com