A method for separating a mixture of carbon-pentadienes

A separation method and technology for diolefins, which are applied in organic chemical methods, chemical instruments and methods, adsorption purification/separation, etc., can solve the problem of low separation selectivity of C5 diolefin system, low adsorption and separation selectivity, and inability to achieve sieving. Separation and other problems, to achieve the effect of high capacity and selectivity, environmental friendliness, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

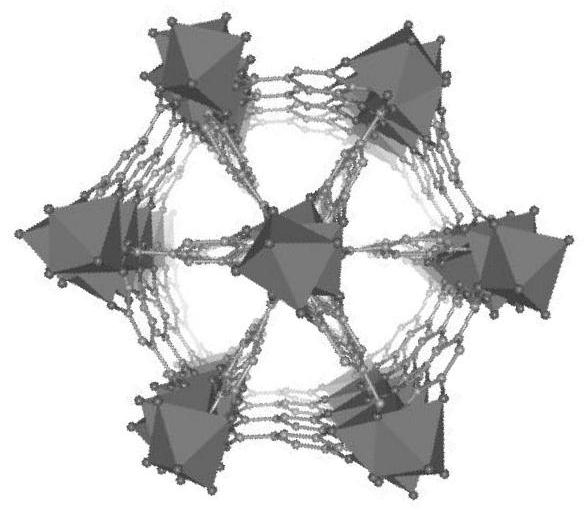

[0072] Mix 2mmol of anhydrous magnesium chloride, 4mmol of gallic acid, 5mmol of potassium hydroxide, and 10mL of deionized water, put them into a 25mL hydrothermal reaction kettle, stir for half an hour, put them in an oven, and react at 120°C for 24 hours. After the reaction, it was naturally cooled to room temperature, and the solid obtained in the reaction was washed with water and ethanol several times in sequence to obtain the purified metal-organic framework material Mg-gallate. The purified adsorbent was vacuum degassed at 120 °C for 24 hours to obtain the desolventized adsorbent, and then the next gas adsorption experiment and breakthrough experiment were performed.

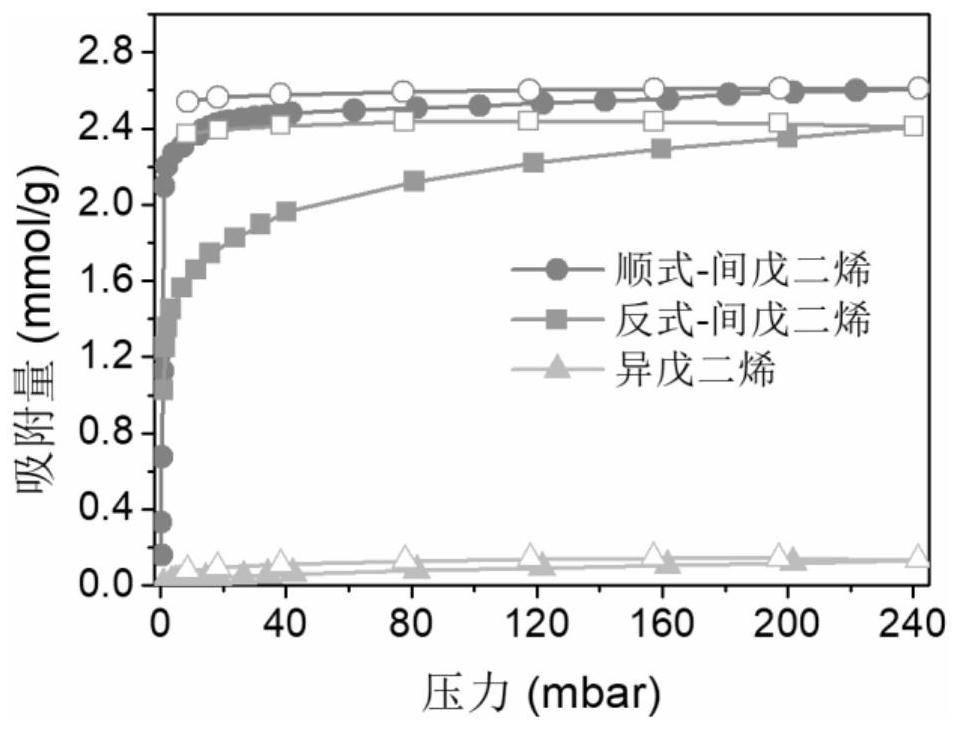

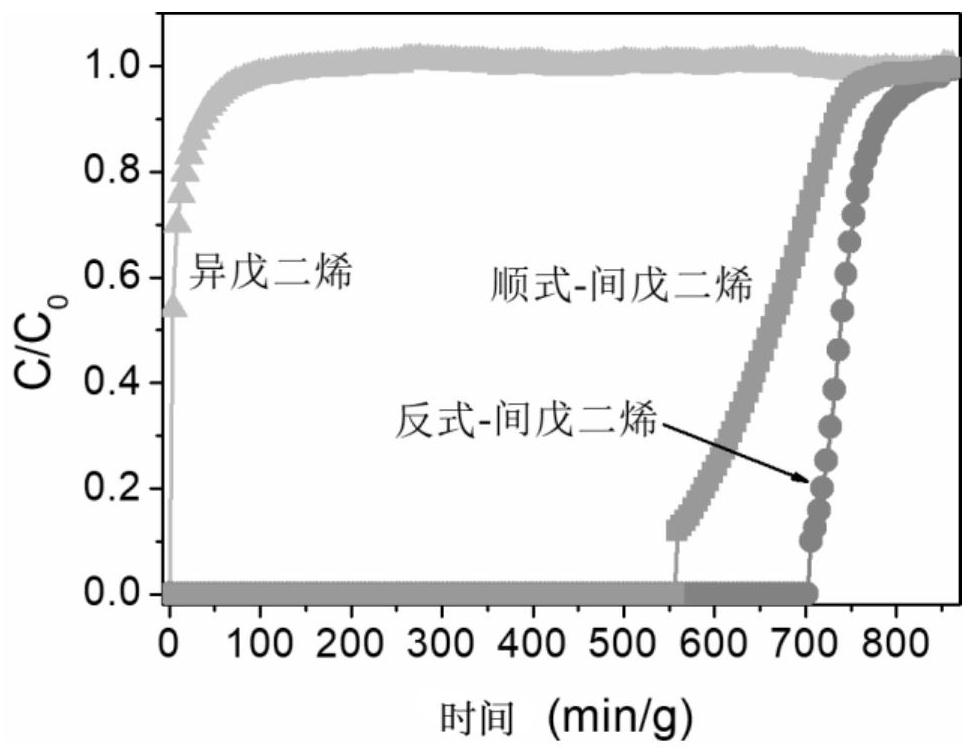

[0073] To test the adsorption-separation performance of the above-synthesized MOFs, single-component adsorption isotherms of trans-piperylene, cis-piperylene, and isoprene were carried out using the above-mentioned adsorbents. The single-component adsorption isotherms of the three gases of this material ...

Embodiment 2

[0076] Mix 2mmol cobalt chloride hexahydrate, 4mmol gallic acid, 1.6mmol potassium hydroxide, and 10mL deionized water, put it into a 25mL hydrothermal reaction kettle, stir for half an hour, put it in an oven, and react at 120°C for 24 hours. After the reaction, it was naturally cooled to room temperature, and the solid obtained in the reaction was washed with water and ethanol several times in sequence to obtain the purified metal organic framework material Co-gallate. The purified adsorbent was vacuum degassed at 120 °C for 24 hours to obtain the desolventized adsorbent, and then the next gas adsorption experiment and breakthrough experiment were performed.

[0077] To test the adsorption-separation performance of the above-synthesized MOFs, single-component adsorption isotherms of trans-piperylene, cis-piperylene, and isoprene were carried out using the above-mentioned adsorbents. The single-component adsorption isotherms of the three gases of this material are shown in ...

Embodiment 3

[0080] Mix 2mmol nickel chloride hexahydrate, 4mmol gallic acid, 1.6mmol potassium hydroxide, and 10mL deionized water, put them into a 25mL hydrothermal reaction kettle, stir for half an hour, put them in an oven, and react at 120°C for 24 hours. After the reaction, it was naturally cooled to room temperature, and the solid obtained in the reaction was washed with water and ethanol several times in sequence to obtain the purified metal organic framework material Ni-gallate. The purified adsorbent was vacuum degassed at 120 °C for 24 hours to obtain the desolventized adsorbent, and then the next gas adsorption experiment and breakthrough experiment were performed.

[0081] To test the adsorption-separation performance of the above-synthesized MOFs, single-component adsorption isotherms of trans-piperylene, cis-piperylene, and isoprene were carried out using the above-mentioned adsorbents. The single-component adsorption isotherms of the three gases of this material are shown i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com