PMC solid fuel preparation method

A solid fuel, fuel technology, applied in the direction of solid fuel, fuel, biofuel, etc., can solve the problems of difficult to completely burn the central area of the fuel, consume more time, and burn for a long time, so as to improve the decomposition performance, improve the sufficient , the effect of improving combustion ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A kind of PMC solid fuel preparation method, comprises the following steps:

[0035] S1. Mix the fuel raw materials in the raw material bin 1 and send them to the screening machine 2, and then send them to the grinding and drying machine 5 after being screened;

[0036] S2. Connect the grinding and drying machine 5 to the bag-type powder collector 6, and supply heat to it by the hot blast stove 4. After the fuel raw material is ground and dried, it is sent into the bag-type powder collector 6 through the wind separator;

[0037] S3. The fuel raw material is sent to the screw conveyor 8 through the air lock 7 in the bag-type powder collector 6, and the blending additive is quantitatively added to the screw conveyor 8 from the blending and adding bin 9 through the quantitative feeder 91, and conveyed from the screw The tail of the device 8 is sent into the dust collector 10;

[0038] S4. After being dedusted by the dust collector 10, it is sent out by the screw loader 11...

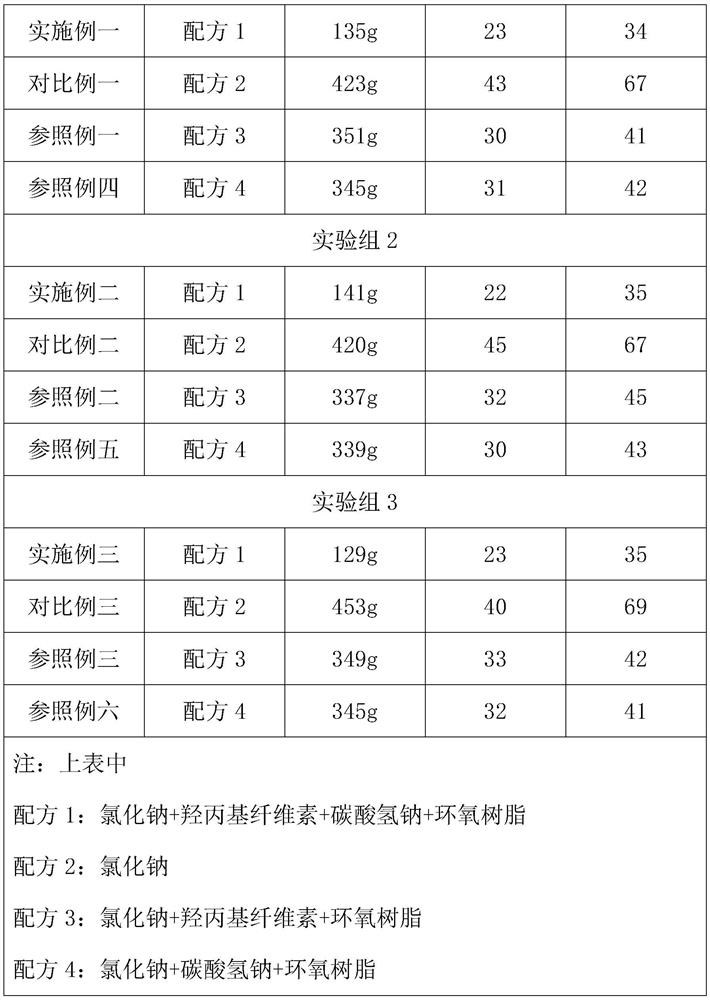

Embodiment 1

[0041] A PMC solid fuel, comprising the following fuel raw materials in parts by mass: 50 parts of charcoal powder, 10 parts of sawdust, 15 parts of paraffin, 6 parts of 95% alcohol, 10 parts of enhanced leavening agent, 10 parts of oxidant, 6 parts of catalyst 5 parts of modified sulfur-fixing additive, 10-12 parts of smoke suppressant and 35 parts of water.

Embodiment 2

[0043] A PMC solid fuel, comprising the following fuel raw materials in parts by mass: 60 parts of charcoal powder, 12 parts of sawdust, 20 parts of paraffin, 8 parts of 95% alcohol, 12 parts of enhanced leavening agent, 11 parts of oxidant, 7 parts of catalyst 6 parts, 6 parts of modified sulfur-fixing additives, 11 parts of smoke suppressant and 45 parts of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com