Integrated self-crosslinking fracturing method, applied fracturing fluid, and preparation method and application thereof

A fracturing fluid and self-crosslinking technology, applied in chemical instruments and methods, production fluids, earthwork drilling, etc., can solve the problems of poor temperature and shear resistance, poor stimulation effect, formation damage, etc. The effect of convenient preparation, measurement and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] As a preference, the thickener can be selected from the thickener formula disclosed in the invention patent application with the application number 201811402402.9 and the invention title "Integrated Self-Crosslinking Emulsion Type Fracturing Fluid Thickener, Its Preparation Method and Application" , the raw materials of the thickener include the following raw material components in terms of mass percentage:

[0039] Oil-soluble solvent 35-50%;

[0040] Deionized water 26-30%;

[0041] Viscosifying monomer 12-15%;

[0042] Modified monomer 5-8%;

[0043] Anionic emulsifying active monomer 2~3%;

[0044] Cationic quaternary ammonium salt type monomer 2~3%;

[0045] Anionic emulsifier 0.5-1%;

[0046] Non-ionic emulsifier 2.5-4%;

[0047] Preferably, the oil-soluble solvent includes any one or a combination of two or more of white oil, silicone oil and petroleum ether;

[0048] As preferably, the tackifying monomer comprises any one or two or more of acrylamide, sod...

Embodiment 1

[0083] Laboratory application and performance testing of the integrated self-crosslinking fracturing method:

[0084] Keep the water temperature at 10°C, add 298.8g of tap water to the liquid preparation equipment, keep stirring, and at the same time add 1.2g of integrated self-crosslinking fracturing fluid thickener, 0.15g of ammonium persulfate and 120cm 3 After the ceramsite is evenly mixed with sand, it becomes an integrated self-crosslinking fracturing fluid. Put it into an aging tank, raise the temperature to 180°C, and break the gel completely after 2 hours to complete the indoor evaluation process.

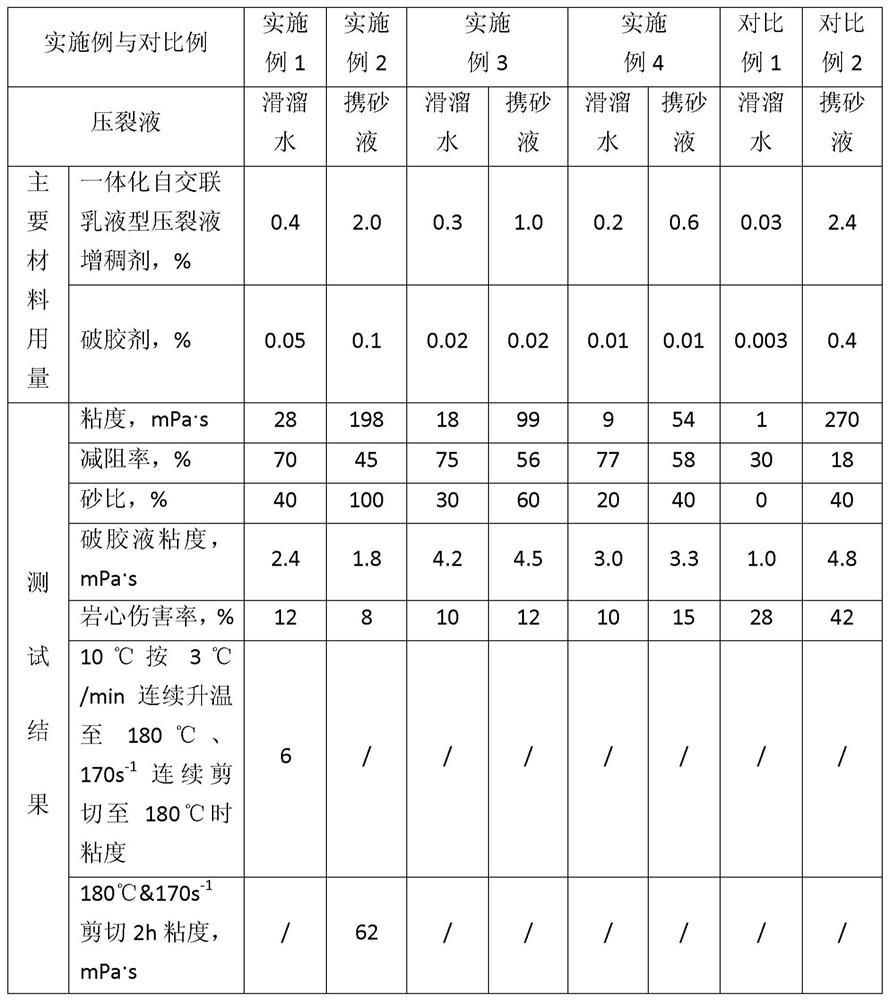

[0085] The integrated self-crosslinking fracturing fluid prepared above is used as slick water. After testing, the viscosity is 28mPa·s, the drag reduction rate is 70%, the sand ratio is 40%, the gel breaking fluid viscosity is 2.4mPa·s, and the core damage rate is 12%. , temperature resistance 180 ° C, 10 ° C at 3 ° C / min continuous heating to 180 ° C, 170s -1 The visco...

Embodiment 2

[0087] Laboratory application and performance testing of the integrated self-crosslinking fracturing method:

[0088] Keep the water temperature at 40°C, add 490.0g of surface water to the liquid preparation equipment, keep stirring, and at the same time add 10.0g of integrated self-crosslinking fracturing fluid thickener, 0.5g of capsule breaker and 500cm 3 Quartz sand, mixed evenly, becomes an integrated self-crosslinking fracturing fluid. Put it into an aging tank, raise the temperature to 180°C, and break the gel completely after 2 hours to complete the indoor evaluation process.

[0089] The integrated self-crosslinking fracturing fluid prepared above is used as a sand-carrying fluid. After testing, the viscosity is 198mPa s, the drag reduction rate is 45%, the sand ratio is 100%, the gel breaking fluid viscosity is 1.8mPa s, and the core damage rate is 8 %, temperature resistance 180°C, 180°C, 170s -1 Shear 90min viscosity 62.0mPa·s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com