Method for extracting nickel from nickel-containing iron powder and preparing iron phosphate and application

A technology of ferronickel powder and ferric phosphate is applied in the field of extracting nickel and preparing ferric phosphate, which can solve the problems of high production cost and equipment maintenance cost, unsuitable promotion and the like, and achieve the effects of low cost, great economic benefit and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

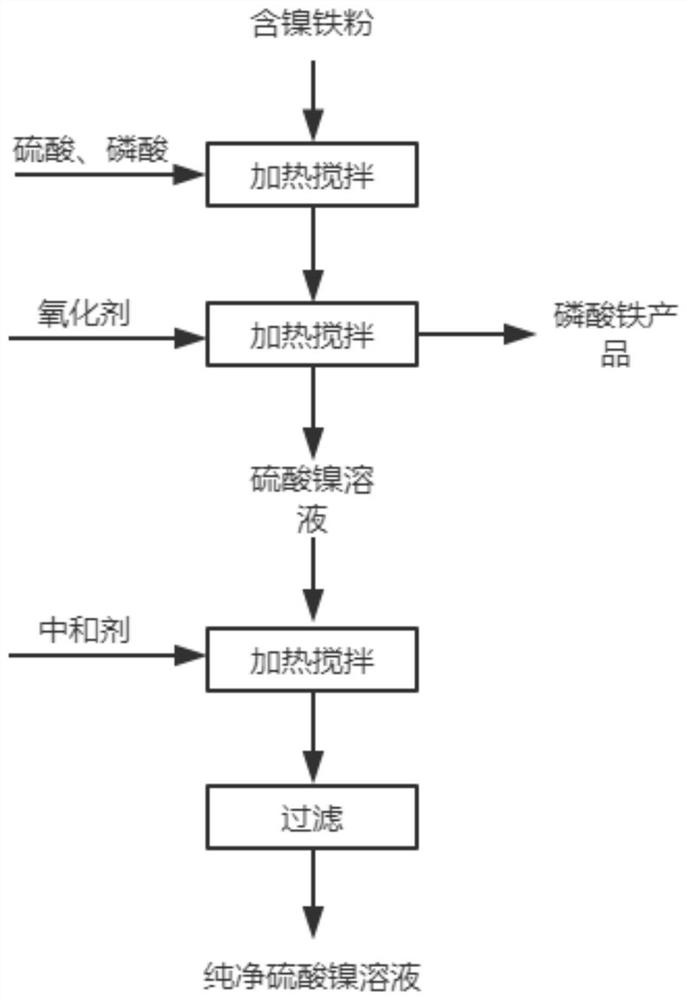

Method used

Image

Examples

Embodiment 1

[0041] A method for extracting nickel from nickel-containing iron powder and preparing iron phosphate, comprising the following steps:

[0042] (1) prepare respectively the sulfuric acid of 2mol / L and the phosphoric acid of 14mol / L, standby;

[0043] (2) Weigh 50g of nickel-containing iron powder, wherein the iron content is 64.13%, the nickel content is 35.67%, add the above-mentioned phosphoric acid of 37mL, then add the above-mentioned sulfuric acid of 250mL, the slurry water bath is heated to 80 ℃, and the stirring time is 3h;

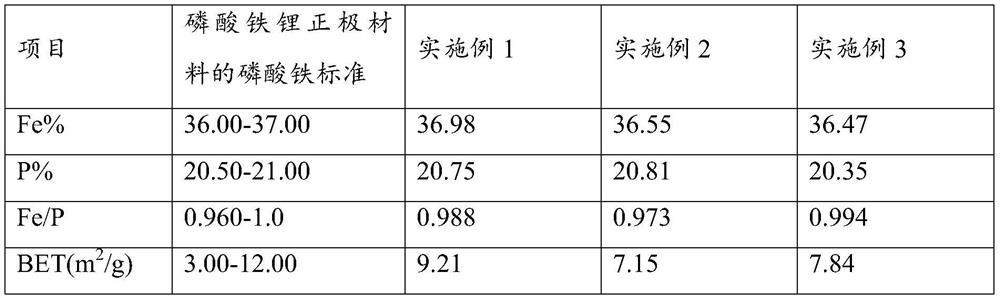

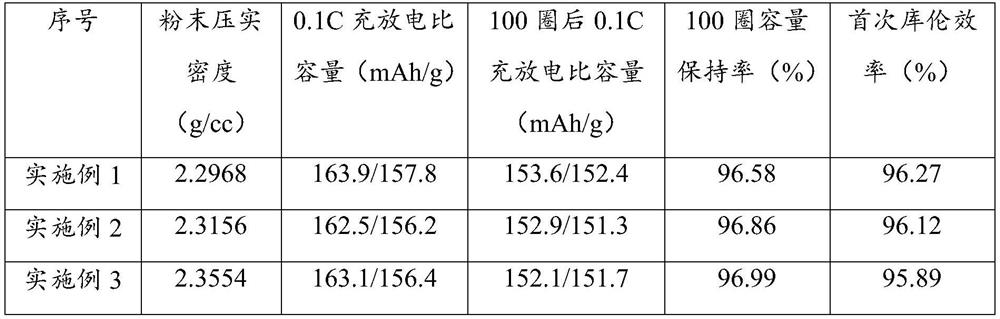

[0044] (3) Add 50 mL of hydrogen peroxide, stir for 1 h, then add 7 g of aluminum hydroxide and ferric phosphate into the solution, heat up to 90° C., stir for 10 h, and filter to obtain ferric phosphate and nickel sulfate solution;

[0045](4) Slurry and wash ferric phosphate with water at a liquid-solid ratio of 5:1mL / g for 1 hour, and dry the ferric phosphate at 105°C after filtering to obtain the ferric phosphate product;

[0046] (5) Add a 2...

Embodiment 2

[0048] A method for extracting nickel from nickel-containing iron powder and preparing iron phosphate, comprising the following steps:

[0049] (1) prepare respectively the sulfuric acid of 1.5mol / L and the phosphoric acid of 13.5mol / L, standby;

[0050] (2) Weigh 100g of nickel-iron powder, wherein the iron content is 69.28%, the nickel content is 30.29%, add the above-mentioned phosphoric acid of 85mL, then add the above-mentioned sulfuric acid of 520mL, the slurry water bath is heated to 85 ℃, stirring time is 4h;

[0051] (3) Add 40mL of hydrogen peroxide, and at the same time pass through 2h of aeration oxygen, then add 15g of titanium dioxide and ferric phosphate dihydrate into the solution, heat up to 80°C, stir for 8h, and filter to obtain ferric phosphate and nickel sulfate solution;

[0052] (4) Slurry and wash ferric phosphate with water at a liquid-solid ratio of 10:1mL / g for 2 hours, filter and dry ferric phosphate at 90°C to obtain ferric phosphate product;

[...

Embodiment 3

[0055] A method for extracting nickel from nickel-containing iron powder and preparing iron phosphate, comprising the following steps:

[0056] (1) prepare respectively the sulfuric acid of 2.5mol / L and the phosphoric acid of 14.5mol / L, standby;

[0057] (2) Weigh 100g of nickel-iron powder, wherein the iron content is 85.42%, the nickel content is 13.95%, add the above-mentioned phosphoric acid of 95mL, then add the above-mentioned sulfuric acid of 200mL, the slurry water bath is heated to 75 ℃, stirring time is 6h;

[0058] (3) Add 100mL of hydrogen peroxide, stir for 0.5h, then add 20g of alumina and titanium dioxide to the solution, heat up to 85°C, stir for 6h, and filter to obtain iron phosphate and nickel sulfate solutions;

[0059] (4) Slurry and wash ferric phosphate with water at a liquid-solid ratio of 8:1mL / g for 0.5h, filter and dry ferric phosphate at 105°C to obtain ferric phosphate product;

[0060] (5) Add 5% sodium hydroxide solution to the nickel sulfate s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com