Inorganic perovskite material, photoelectric detector and preparation method of inorganic perovskite material

A photodetector, inorganic calcium technology, applied in chemical instruments and methods, polycrystalline material growth, metal material coating technology, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Preparation of CsPbBr by anti-solvent diffusion method 3 Single crystal: weigh 3.3g of PbBr 2 and 1.4 g of CsBr were dissolved in 15 ml of DMSO and stirred for more than one hour. Then filter the precursor solution with an organic syringe filter, filter to obtain a clear solution, and filter the clear solution with CH 3 Titrate with OH until an orange-yellow precipitate precipitates, and filter again to obtain a clear solution, which is moved to a place filled with CH 3 In the environment of OH vapor, the ambient temperature was kept at 20 °C, and CsPbBr was obtained after a week of growth. 3 single crystal.

[0027] (2) CsPbBr 3 Preparation of powder: weigh 1.3g of CsPbBr 3 The single crystal is ground into powder in an agate mortar.

[0028] (3) Hot isostatic pressing of CsPbBr 3 Preparation of polycrystalline bulk: CsPbBr 3 The powder was placed in a hot isostatic press, the pressure was set at 20MPa, the temperature was 200°C, and the heating time was 8h...

Embodiment 2

[0031] (1) CsPbBr 3 Laser surface modification of polycrystalline bulk materials: use a 248nm KrF excimer laser, and set the energy density of the laser to 10mJ / cm2 , the laser operating frequency is set to 10Hz, the CsPbBr prepared by step (3) in Example 1 3 The polycrystalline block was irradiated, and the number of irradiation pulses was 30 to obtain laser-modified CsPbBr 3 polycrystalline blocks;

[0032] (2) CsPbBr 3 Fabrication of photodetectors: CsPbBr after laser surface modification 3 Evaporation of Au interdigitated electrodes on polycrystalline bulk to obtain CsPbBr 3 Photodetector.

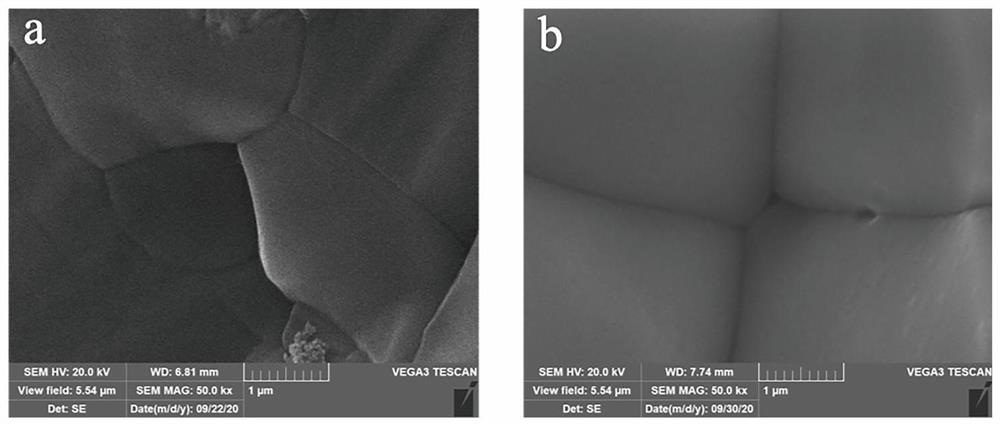

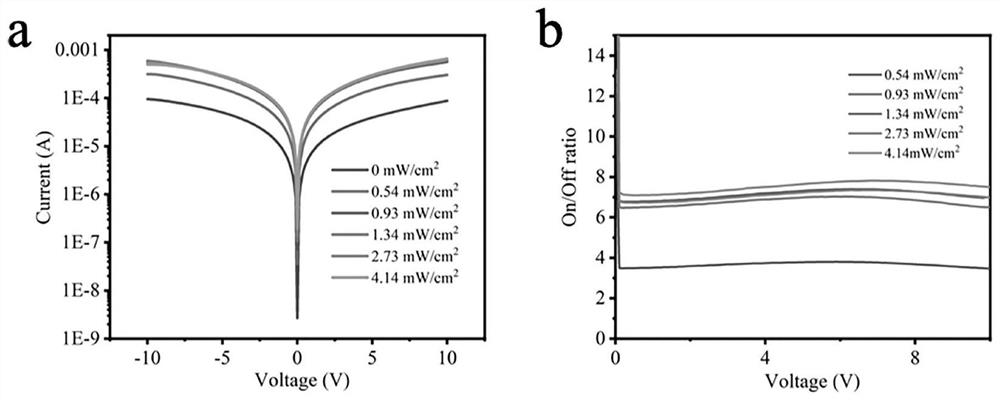

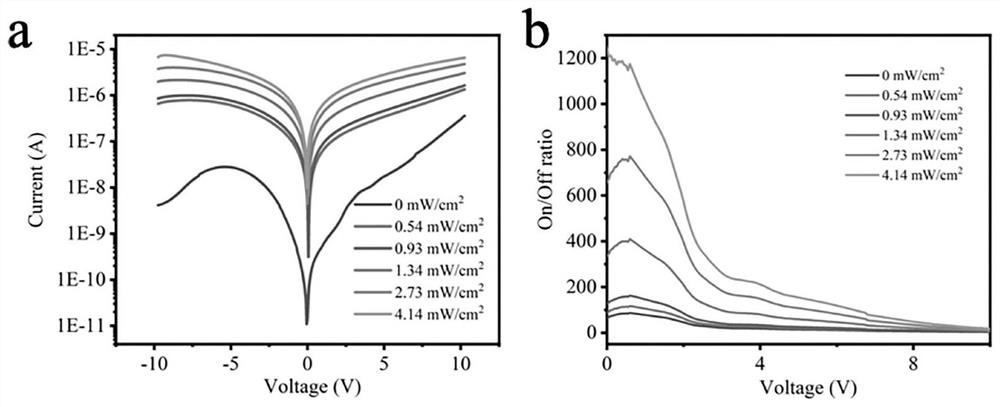

[0033] CsPbBr before and after laser modification in embodiment 1 and 2 3 The cross-sectional scanning SEM image of the polycrystalline bulk material, the results are as follows figure 1 a and figure 1 b shown by figure 1 It can be seen that, compared with before laser modification, CsPbBr after laser modification 3 There are no small particles of CsPbBr on the surface of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com