A flexible conductive metal pattern and its preparation method, application and conductive material

A conductive metal and pattern technology, which is applied in the manufacture of conductive/semiconductive layer equipment, conductive layers on insulating carriers, cable/conductor manufacturing, etc., can solve the problems of poor conductivity and damage of patterns, and achieve good flexibility, The effect of simple and time-saving process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

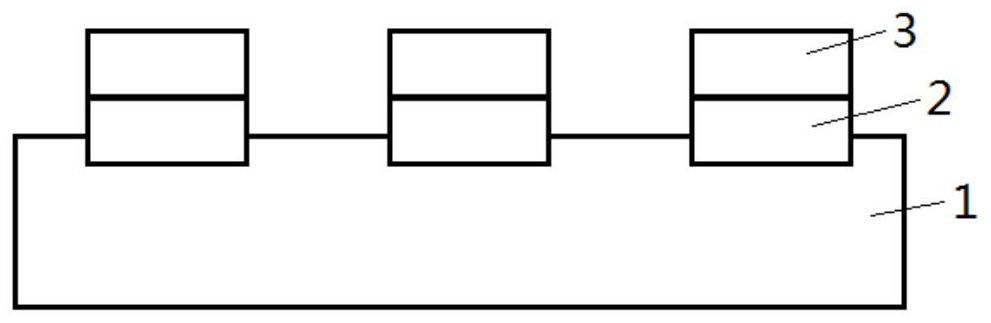

[0045] This embodiment provides a method for preparing a flexible conductive metal pattern, which includes the following steps:

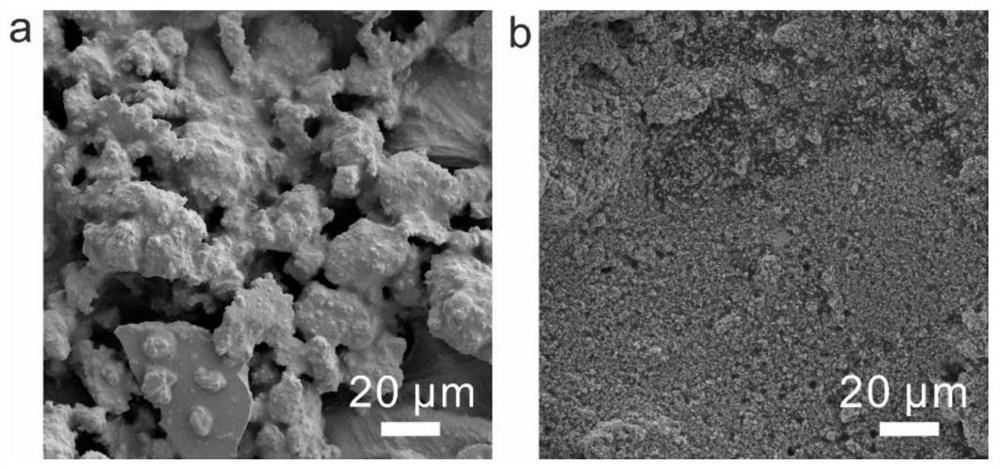

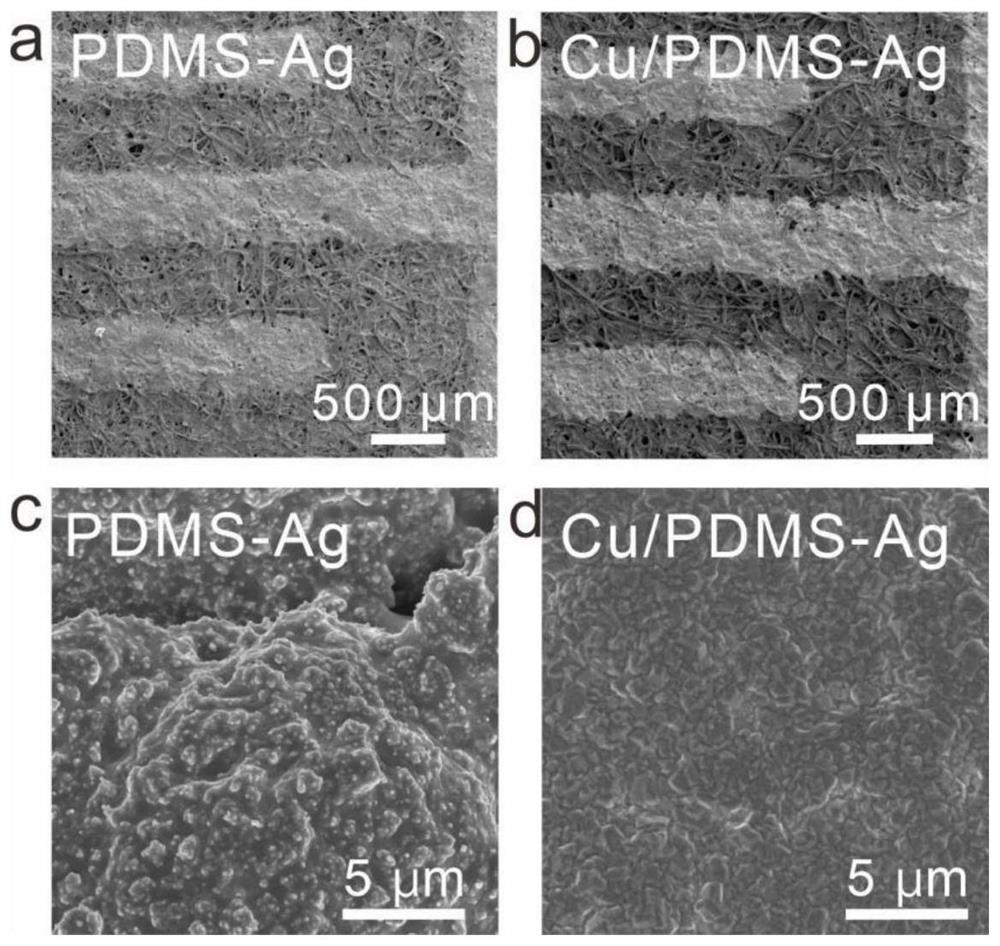

[0046] Ag nanoparticles capped with rosin are mixed and stirred with 3-aminopropyltriethoxysilane solution accounting for 5% of the mass of Ag to form a silane molecular film by self-assembly on the surface of the Ag particles. The polydimethylsiloxane prepolymer (Dow Corning, sylgard 184) and the curing agent (small molecule silane) were mixed in a mass ratio of 10:1, and the above-treated silver nanoparticles (particle size 50% of the total mass) were added. 60-100 nanometers), the mixture of the three is fully stirred until the mixture is uniform to obtain ink. The ink with a certain pattern is printed on the surface of the qualitative filter paper by the screen printing process (the width of the hollow line is 500 microns and the line spacing is 500 microns), and the thickness is about 8 microns, and it is dried at 80 ° C for 2 hours; Immerse i...

Embodiment 2

[0051] Ag nanoparticles capped with rosin are mixed and stirred with 3-aminopropyltriethoxysilane solution accounting for 5% of the mass of Ag to form a silane molecular film by self-assembly on the surface of the Ag particles. Mix the polydimethylsiloxane prepolymer and the curing agent (small molecular silane) in a mass ratio of 10:1, and add the above-treated silver nanoparticles (with a particle size of 60 to 100 nanometers) that account for 50% of the total mass. ), the mixture of the three is fully stirred until the mixture is uniform to obtain ink. A large-area ink pattern with a length of 10 cm and a width of 10 cm was printed on the surface of the qualitative filter paper by a large-area screen printing process, with a thickness of about 8 microns, and dried at 80 °C for 2 hours; the filter paper printed with PDMS-Ag ink was immersed in Swell in tetrahydrofuran solution for 15 minutes; then immerse the swollen substrate in electroless copper plating solution for 30 mi...

Embodiment 3

[0058] This embodiment provides a method for preparing a flexible conductive metal pattern, which includes the following steps:

[0059] Mix the polydimethylsiloxane prepolymer with the curing agent (small molecular silane) in a mass ratio of 10:1, add 60% of the total mass of nickel nanoparticles (the particle size is less than 100 nanometers), and mix the three The mixture was sonicated for 30 minutes and stirred well to obtain ink. The ink with a certain pattern is printed on the surface of the dust-free paper by the screen printing process (the width of the hollow line is 500 microns and the line spacing is 500 microns), and the thickness is about 9 microns. The filter paper was immersed in the acetone solution to swell for 10 minutes; then the swollen substrate was immersed in the electroless nickel plating solution for 1 hour, and the A component of the electroless nickel plating solution was: Ni 2 SO 4 ·5H 2 O (40 g / L), sodium citrate (20 g / L), lactic acid (10 g / L); ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com