Dry electrode and preparation method thereof

A dry electrode and conductive agent technology, which is applied in electrode manufacturing, electrode rolling/calendering, battery electrodes, etc., can solve the problems affecting the power performance of the battery cell, limiting the amount of active material, and the content of binders, etc., to achieve the appearance of molding Good, prevent powder dropping and cracking, high peel strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

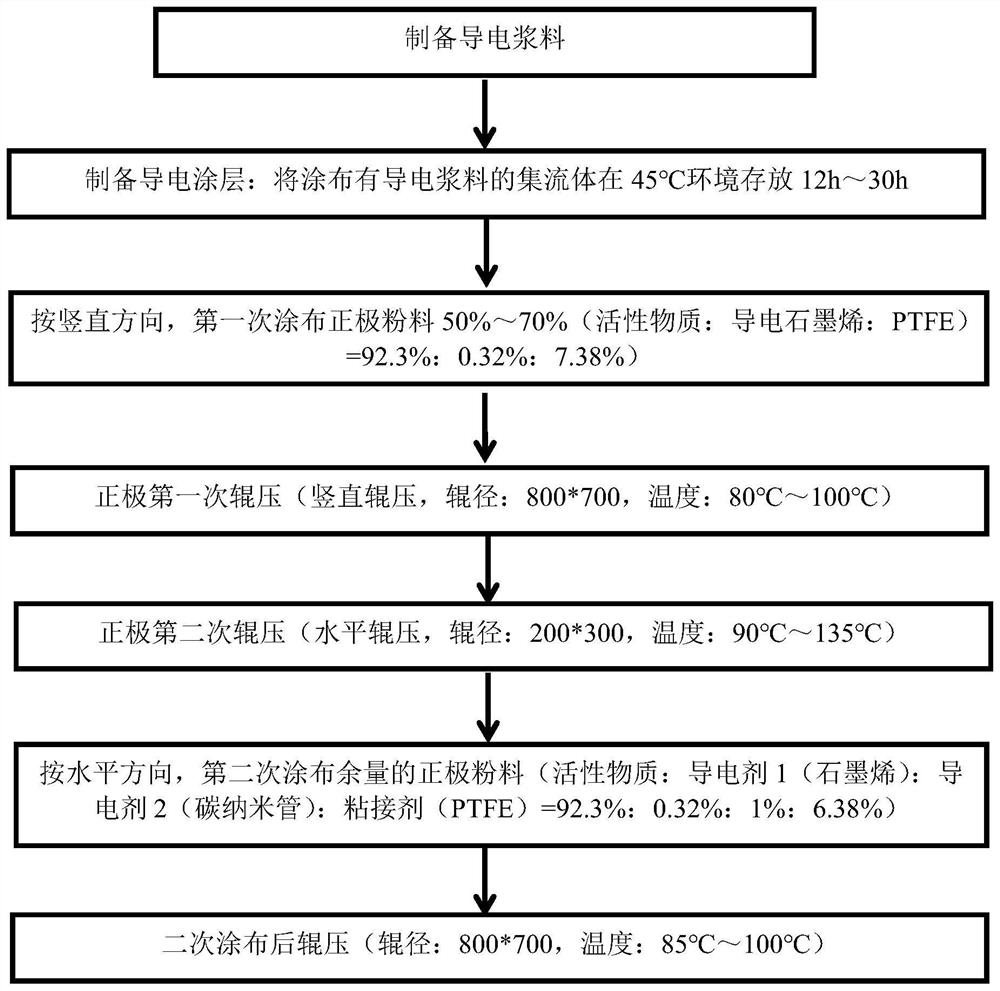

[0062] A preparation method for a dry electrode, comprising the steps of:

[0063] Step 1: preparing powder, which at least includes the following raw materials in mass percentage:

[0064] Active substance 90%~97%,

[0065] Conductive agent 0.1%~2%,

[0066] Adhesive 2.9%~9.9%;

[0067] Step 2: Coating powder accounting for 10% to 90% of the total mass of the powder on the current collector, performing multiple rolling treatments, and preparing an intermediate;

[0068] During the preparation of the intermediate, at least one rolling treatment has a pressure roller traveling direction parallel to the coating direction;

[0069] Step 3: Coating the rest of the powder on the intermediate, and performing rolling treatment to prepare a dry electrode.

[0070] The preparation method of the dry electrode provided by the invention includes a specific powder composition, a step-by-step feeding method and a specific rolling treatment method. Specifically, in terms of mass percent...

Embodiment 1

[0148] This embodiment provides a conductive rubber material, a preparation method thereof, and a current collector aluminum foil coated with a conductive coating.

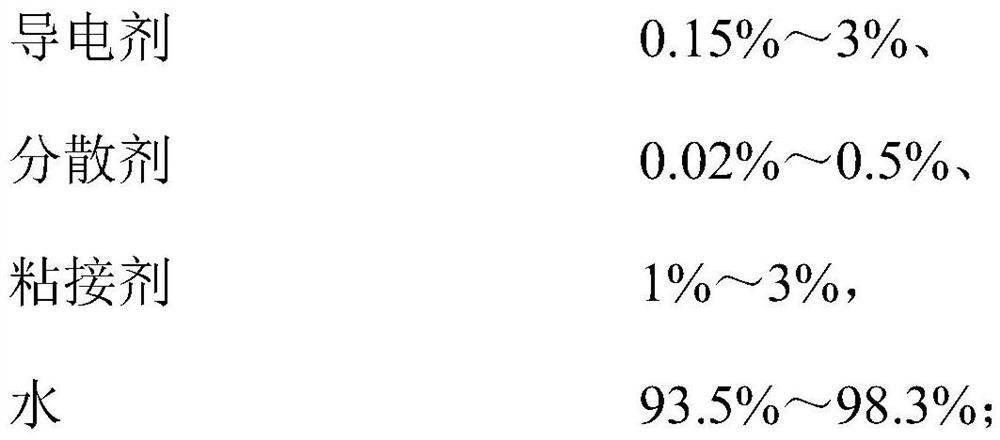

[0149] (1) The conductive adhesive is prepared from the following raw materials in mass percentage:

[0150]

[0151]

[0152] Wherein the sheet diameter of the graphene is 30 μm, the diameter of the multi-walled carbon nanotube is 5 nm to 70 nm, and the aspect ratio is 1000 to 1500.

[0153] (2) Prepare conductive paste:

[0154] Ultrasonic dispersion of graphene, multi-walled carbon nanotubes and sodium dodecylbenzenesulfonate in deionized water with an ultrasonic instrument to obtain a mixed solution A, the ultrasonic power is 1500W, and the ultrasonic time is 80min;

[0155] Mixing the adhesive and deionized water to obtain a mixed solution B;

[0156] The mixed solution A and the mixed solution B were stirred and mixed uniformly for 100 min to obtain a conductive paste.

[0157] (3) Preparation of po...

Embodiment 2

[0160] This embodiment provides positive electrode powder and a preparation method thereof.

[0161] (1) The positive electrode powder 1 is prepared from the following raw materials in mass percentage:

[0162] Lithium iron phosphate 92.3%;

[0163] Graphene 0.32%;

[0164] PTFE 7.38%.

[0165] The positive electrode powder 2 is prepared from the following raw materials in mass percentage:

[0166]

[0167] (2) Preparation of powder:

[0168] Preparation of powder 1: Using a three-dimensional dry-process high-speed dispersion equipment, the lithium iron phosphate, carbon black and PTFE were uniformly mixed and fibrillated to obtain positive electrode powder 1, which was set aside.

[0169] Preparation of powder 2: Using a three-dimensional dry-process high-speed dispersion equipment, the lithium iron phosphate, graphene, carbon nanotubes, and PTFE were uniformly mixed and fibrillated to obtain positive electrode powder 2, which was set aside.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com